Page 67: of Maritime Reporter Magazine (March 15, 1969)

Read this page in Pdf, Flash or Html5 edition of March 15, 1969 Maritime Reporter Magazine

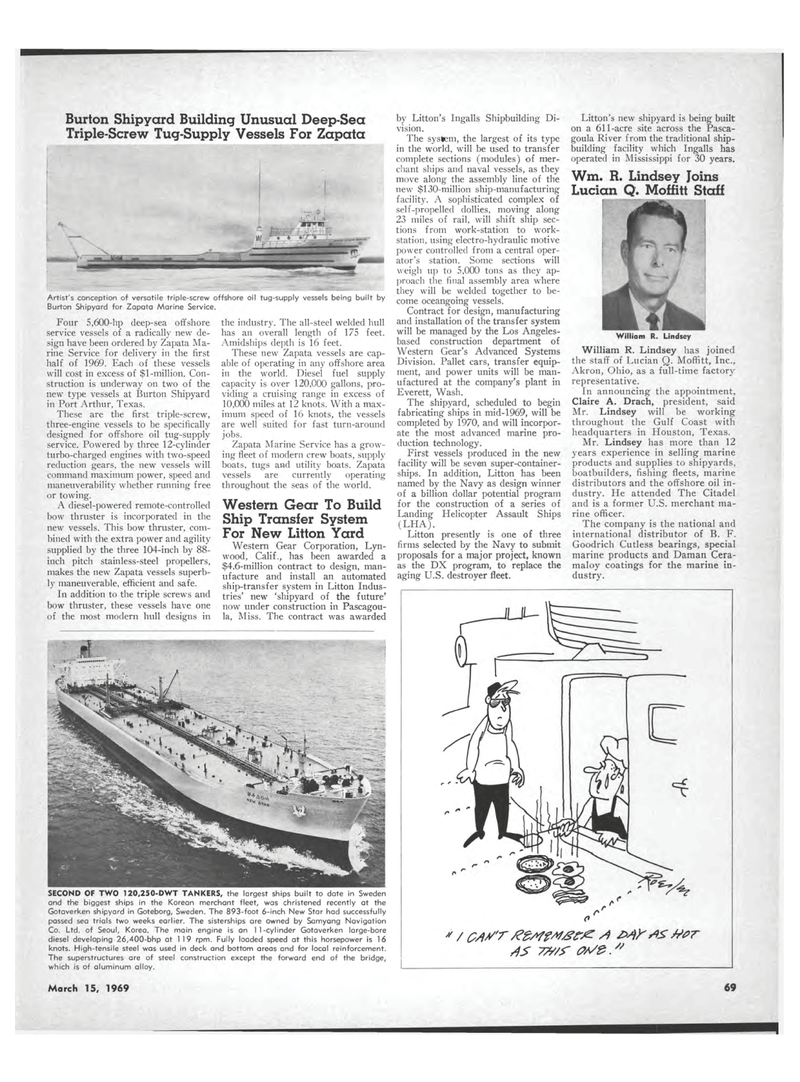

Burton Shipyard Building Unusual Deep-Sea Triple-Screw Tug-Supply Vessels For Zapata I « fc Artist's conception of versatile triple-screw offshore oil tug-supply vessels being built by Burton Shipyard for Zapata Marine Service. Four 5,600-hp deep-sea offshore service vessels of a radically new de-sign have been ordered by Zapata Ma-rine Service for delivery in the first half of 1969. Each of these vessels will cost in excess of $l-million. Con-struction is underway on two of the new type vessels at Burton Shipyard in Port Arthur. Texas. These are the first triple-screw, three-engine vessels to be specifically designed for offshore oil tug-supply service. Powered by three 12-cylinder turbo-charged engines with two-speed reduction gears, the new vessels will command maximum power, speed and maneuverability whether running free or towing. A diesel-powered remote-controlled bow thruster is incorporated in the new vessels. This bow thruster, com-bined with the extra power and agility supplied by the three 104-inch by 88-inch pitch stainless-steel propellers, makes the new Zapata vessels superb-ly maneuverable, efficient and safe. In addition to the triple screws and bow thruster, these vessels have one of the most modern hull designs in the industry. The all-steel welded hull has an overall length of 175 feet. Amidships depth is 16 feet. These new Zapata vessels are cap-able of operating in any offshore area in the world. Diesel fuel supply capacity is over 120,000 gallons, pro-viding a cruising range in excess of 10,000 miles at 12 knots. With a max-imum speed of 16 knots, the vessels are well suited for fast turn-around jobs. Zapata Marine Service has a grow-ing fleet of modern crew boats, supply boats, tugs and utility boats. Zapata vessels are currently operating throughout the seas of the world. Western Gear To Build Ship Transfer System For New Litton Yard Western Gear Corporation, Lyn-wood, Calif., has been awarded a $4.6-million contract to design, man-ufacture and install an automated ship-transfer system in Litton Indus-tries' new 'shipyard of the future' now under construction in Pascagou-la, Miss. The contract was awarded by Litton's Ingalls Shipbuilding Di-vision. The system, the largest of its type in the world, will be used to transfer complete sections (modules) of mer-chant ships and naval vessels, as they move along the assembly line of the new $130-million ship-manufacturing facility. A sophisticated complex of self-propelled dollies, moving along 23 miles of rail, will shift ship sec-tions from work-station to work-station, using electro-hydraulic motive power controlled from a central oper-ator's station. Some sections will weigh up to 5,000 tons as they ap-proach the final assembly area where they will be welded together to be-come oceangoing vessels. Contract for design, manufacturing and installation of the transfer system will be managed by the Los Angeles-based construction department of Western Gear's Advanced Systems Division. Pallet cars, transfer equip-ment, and power units will be man-ufactured at the company's plant in Everett, Wash. The shipyard, scheduled to begin fabricating ships in mid-1969, will be completed by 1970, and will incorpor-ate the most advanced marine pro-duction technology. First vessels produced in the new facility will be seven super-container-ships. In addition, Litton has been named by the Navy as design winner of a billion dollar potential program for the construction of a series of Landing Helicopter Assault Ships (LHA). Litton presently is one of three firms selected by the Navy to submit proposals for a major project, known as the DX program, to replace the aging U.S. destroyer fleet. Litton's new shipyard is being built on a 611-acre site across the Pasca-goula River from the traditional ship-building facility which Ingalls has operated in Mississippi for 30 years. Wm. R. Lindsey Joins Lucian Q. Moffitt Staff William R. Lindsey William R. Lindsey has joined the staff of Lucian Q. Moffitt, Inc., Akron, Ohio, as a full-time factory representative. In announcing the appointment, Claire A. Drach, president, said Mr. Lindsey will be working throughout the Gulf Coast with headquarters in Houston, Texas. Mr. Lindsey has more than 12 years experience in selling marine products and supplies to shipyards, boatbuilders, fishing fleets, marine distributors and the offshore oil in-dustry. He attended The Citadel and is a former U.S. merchant ma-rine officer. The company is the national and international distributor of B. F. Goodrich Cutless bearings, special marine products and Daman Cera-maloy coatings for the marine in-dustry. * / o/iyr /ezAffM&r^ ^ MT /)s 7?//$- pa/ SECOND OF TWO 120,250-DWT TANKERS, the largest ships built to date in Sweden and the biggest ships in the Korean merchant fleet, was christened recently at the Gotaverken shipyard in Goteborg, Sweden. The 893-foot 6-inch New Star had successfully passed sea trials two weeks earlier. The sisterships are owned by Samyang Navigation Co. Ltd. of Seoul, Korea. The main engine is an 11-cylinder Gotaverken large-bore diesel developing 26,400-bhp at 1 19 rpm. Fully loaded speed at this horsepower is 16 knots. High-tensile steel was used in deck and bottom areas and for local reinforcement. The superstructures are of steel construction except the forward end of the bridge, which is of aluminum alloy. March 15, 1969

66

66

68

68