Page 20: of Maritime Reporter Magazine (April 15, 1969)

Read this page in Pdf, Flash or Html5 edition of April 15, 1969 Maritime Reporter Magazine

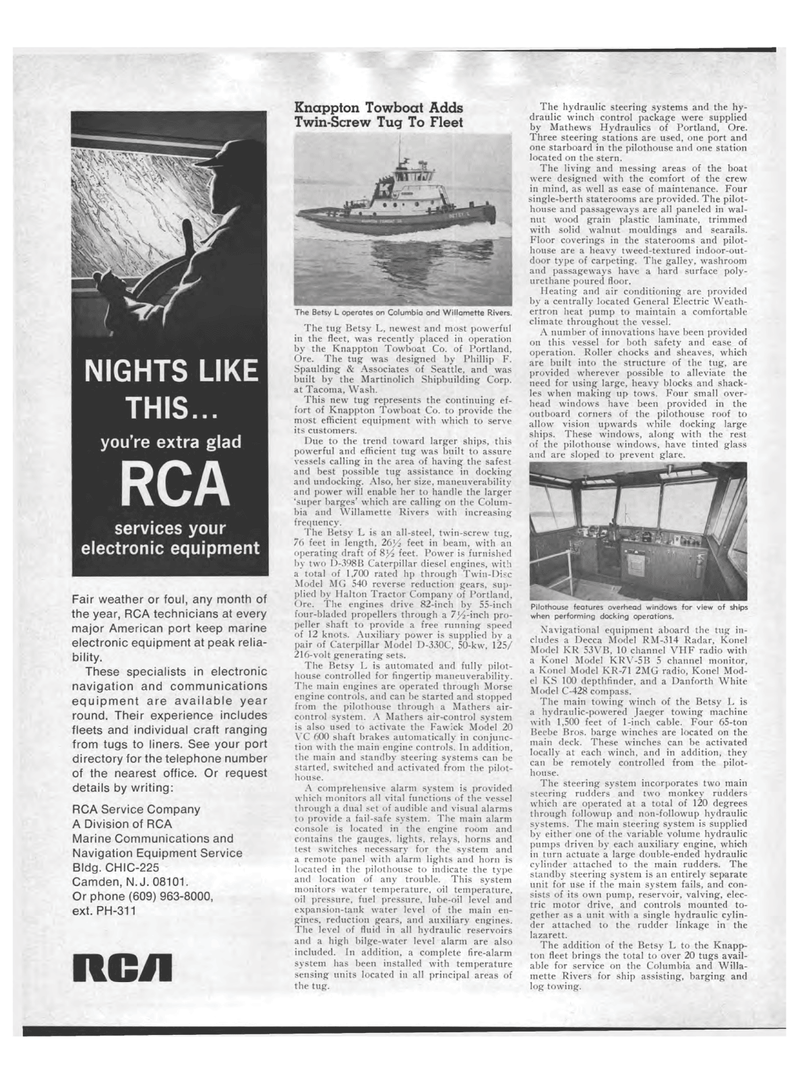

/ Vf NIGHTS LIKE THIS... you're extra glad RCA services your electronic equipment Fair weather or foul, any month of the year, RCA technicians at every major American port keep marine electronic equipment at peak relia-bility. These specialists in electronic navigation and communications equipment are available year round. Their experience includes fleets and individual craft ranging from tugs to liners. See your port directory for the telephone number of the nearest office. Or request details by writing: RCA Service Company A Division of RCA Marine Communications and Navigation Equipment Service Bldg. CHIC-225 Camden, N.J. 08101. Or phone (609) 963-8000, ext. PH-311 VtCJl Knappton Towboat Adds Twin-Screw Tug To Fleet The Betsy L operates on Columbia and Willamette Rivers. The tug Betsy L, newest and most powerful in the fleet, was recently placed in operation by the Knappton Towboat Co. of Portland, Ore. The tug was designed by Phillip F. Spaulding & Associates of Seattle, and was built by the Martinolich Shipbuilding Corp. at Tacoma, Wash. This new tug represents the continuing ef-fort of Knappton Towboat Co. to provide the most efficient equipment with which to serve its customers. Due to the trend toward larger ships, this powerful and efficient tug was built to assure vessels calling in the area of having the safest and best possible tug assistance in docking and undocking. Also, her size, maneuverability and power will enable her to handle the larger 'super barges' which are calling on the Colum-bia and Willamette Rivers with increasing frequency. The Betsy L is an all-steel, twin-screw tug, 76 feet in length. 26Yz feet in beam, with an operating draft of 8^2 feet. Power is furnished by two D-398B Caterpillar diesel engines, with a total of 1,700 rated hp through Twin-Disc Model MG 540 reverse reduction gears, sup-plied by Halton Tractor Company of Portland, Ore. The engines drive 82-inch by 55-inch four-bladed propellers through a inch pro-peller shaft to provide a free running speed of 12 knots. Auxiliary power is supplied by a pair of Caterpillar Model D-330C, 50-kw, 125/ 216-volt generating sets. The Betsy L is automated and fully pilot-house controlled for fingertip maneuverability. The main engines are operated through Morse engine controls, and can be started and stopped from the pilothouse through a Mathers air-control system. A Mathers air-control system is also used to activate the Fawick Model 20 YC 600 shaft brakes automatically in conjunc-tion with the main engine controls. In addition, the main and standby steering systems can be started, switched and activated from the pilot-house. A comprehensive alarm system is provided which monitors all vital functions of the vessel through a dual set of audible and visual alarms to provide a fail-safe system. The main alarm console is located in the engine room and contains the gauges, lights, relays, horns and test switches necessary for the system and a remote panel with alarm lights and horn is located in the pilothouse to indicate the type and location of any trouble. This system monitors water temperature, oil temperature, oil pressure, fuel pressure, lube-oil level and expansion-tank water level of the main en-gines, reduction gears, and auxiliary engines. The level of fluid in all hydraulic reservoirs and a high bilge-water level alarm are also included. I11 addition, a complete fire-alarm system has been installed with temperature sensing units located in all principal areas of the tug. The hydraulic steering systems and the hy-draulic winch control package were supplied by Mathews Hydraulics of Portland, Ore. Three steering stations are used, one port and one starboard in the pilothouse and one station located on the stern. The living and messing areas of the boat were designed with the comfort of the crew in mind, as well as ease of maintenance. Four single-berth staterooms are provided. The pilot-house and passageways are all paneled in wal-nut wood grain plastic laminate, trimmed with solid walnut mouldings and searails. Floor coverings in the staterooms and pilot-house are a heavy tweed-textured indoor-out-door type of carpeting. The galley, washroom and passageways have a hard surface poly-urethane poured floor. Heating and air conditioning are provided by a centrally located General Electric Weath-ertron heat pump to maintain a comfortable climate throughout the vessel. A number of innovations have been provided on this vessel for both safety and ease of operation. Roller chocks and sheaves, which are built into the structure of the tug, are provided wherever possible to alleviate the need for using large, heavy blocks and shack-les when making up tows. Four small over-head windows have been provided in the outboard corners of the pilothouse roof to allow vision upwards while docking large ships. These windows, along with the rest of the pilothouse windows, have tinted glass and are sloped to prevent glare. Pilothouse features overhead windows for view of ships when performing docking operations. Navigational equipment aboard the tug in-cludes a Decca Model RM-314 Radar, Konel Model KR 53YB, 10 channel VHF radio with a Konel Model KRV-5B 5 channel monitor, a Konel Model KR-71 2MG radio, Konel Mod-el KS 100 depthfinder, and a Danforth White Model C-428 compass. The main towing winch of the Betsy L is a hydraulic-powered Jaeger towing machine with 1,500 feet of l-inch cable. Four 65-ton Beebe Bros, barge winches are located on the main deck. These winches can be activated locally at each winch, and in addition, they can be remotely controlled from the pilot-house. The steering system incorporates two main steering rudders and two monkey rudders which are operated at a total of 120 degrees through followup and non-followup hydraulic systems. The main steering system is supplied by either one of the variable volume hydraulic pumps driven by each auxiliary engine, which in turn actuate a large double-ended hydraulic cylinder attached to the main rudders. The standby steering system is an entirely separate unit for use if the main system fails, and con-sists of its own pump, reservoir, valving, elec-tric motor drive, and controls mounted to-gether as a unit with a single hydraulic cylin-der attached to the rudder linkage in the lazarett. The addition of the Betsy L to the Knapp-ton fleet brings the total to over 20 tugs avail-able for service on the Columbia and Willa-mette Rivers for ship assisting, barging and log towing.

19

19

21

21