Page 4: of Maritime Reporter Magazine (April 15, 1969)

Read this page in Pdf, Flash or Html5 edition of April 15, 1969 Maritime Reporter Magazine

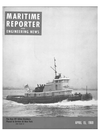

Twin-Screw Diesel Tug For Unlimited Operations The MT Gillen Brothers Wheelhouse has equipment conveniently located for easy use by the tug's master. Combined galley and messroom is equipped for long voyages with freezer and storerooms. Engine room provides ample work area around Caterpillar engines and Lufkin reverse/reduction gears. When the MT Gillen Brothers recently joined the fleet of Henry Gillen's Sons Lighterage, Inc., it marked an expansion move that added considerably to the poten-tial of this over 100-year-old firm. This tug is classed by the Ameri-can Bureau of Shipping for ocean service. This addition to the fleet expands the firm's facilities for all types of towing operations ? harbor, coastal and ocean. The Gillen Brothers was built by Jakobson Shipyard, Inc. at Oys-ter Bay, Long Island, N.Y. It has an overall length of 100 feet, a beam of 28 feet 9 inches and a depth of 13 feet 6 inches. Twin-screw propulsion is provid-ed by two Caterpillar, Model D399, 16-cylinder turbocharged diesel en-gines. Each engine is rated at 1,225 hp, having a full-load rpm of 1,225. The engines drive the propellers through Lufkin reverse-reduction gears, with a reduction ratio of 5.25 to 1. The exhaust from each engine is led through a Baird-Max-im spark arresting silencer. Air for engine starting is provided by two Quincy, Model D325-12 com-pressors. The compressors are op-erated automatically by a Square D pressure switch set to start the compressors at 120 psi and to shut off at 150 psi. The main engines and the clutch-es are controlled from either the engine room or the wheelhouse by means of a Westinghouse Air Brake engine control system. Electric power is supplied by two 40-kw, 240/480 volt, three-phase, 60-cycle General Electric genera-tors driven by Caterpillar, Model D320 diesel engines. Each engine exhausts through its own Baird-Maxim muffler. The electrical sys-tem includes an H.O. Penn genera-tor switch panel, Empire Electric distribution switch panel and Gen-eral Electric 10-kva transformer. The steering gear was supplied complete by Propulsion Systems Inc. Following the present-day trend, the helmsman's wheel has been replaced by a lever. The sys-tem includes full follow-up in the pilothouse and a non-follow-up af-ter deck steering unit. Quarters have been provided for ten men. However, the normal operating crew consists of six men. The vessel is equipped with a cen-tral ventilation system for the quarters, using a Buffalo Forge fan. The engine room has two separate Buffalo Forge air-supply fans. Heat for the tug is supplied by a Crane boiler, Model 82-396, with a maxi-mum working pressure of 15 psi and equipped with an Automatic Burner Corp. oil burner. Hot water is supplied by a Crane, 82-gallon electric heater. The combined galley and mess-room is modern in all respects. The electric range is an Akron Model G-436K1R. There is a large Foster refrigerator/freezer installed in the galley along with stainless-steel sinks, racks, etc. Deck equipment, besides the effi-ciently located bitts and cleats, con-sists of a New England Trawler capstan on the aft deck which is driven by an Imperial Electric two-speed, 20-hp motor. All rope was supplied by Cating Rope Works, Inc. of Maspeth, L.I., N.Y. The wheelhouse provides for a clear view in all directions. The large Kearfott window in front of the helmsman is electrically heated and fitted with a Sprague air wind-shield wiper. It is completely out-fitted for harbor, coastal and ocean service. There is installed a Sperry Mark XIV, Model 1 master gyro compass, a Kelvin White 7-inch Constellation magnetic compass, a Decca radar, and an Apelco Model DFR-200 direction finder. Radio communication is provid-ed by a Kaar Electronics Model TR222A radio telephone and Clip-per II YHF marine radio. For in-terior communication there is a Hose-McCann sound-powered tele-phone system connecting the pilot-house, engine room, chief engi-neer's room, control room and the galley. Navigation lights are con-trolled from a Hose-McCann panel. Portable Light Company supplied Radio equipment and automation panel is located on aft bulkhead of wheelhouse. 1,000-watt searchlights for the pilothouse top and the boat deck, while the floodlights were supplied by Pyle-National. The MT Gillen Brothers is a worthy successor to the first vessel with the same name. The original Gillen Brothers was a wooden-hulled steam lighter built in 1909. It saw service around New York Harbor for over 30 years. Electrical switchboard contains distribution panel (left), generator panel (center), and capstan control (right). Automation control is located in control room on the main deck. 6 Maritime Reporter/Engineering News

3

3

5

5