Page 31: of Maritime Reporter Magazine (May 1969)

Read this page in Pdf, Flash or Html5 edition of May 1969 Maritime Reporter Magazine

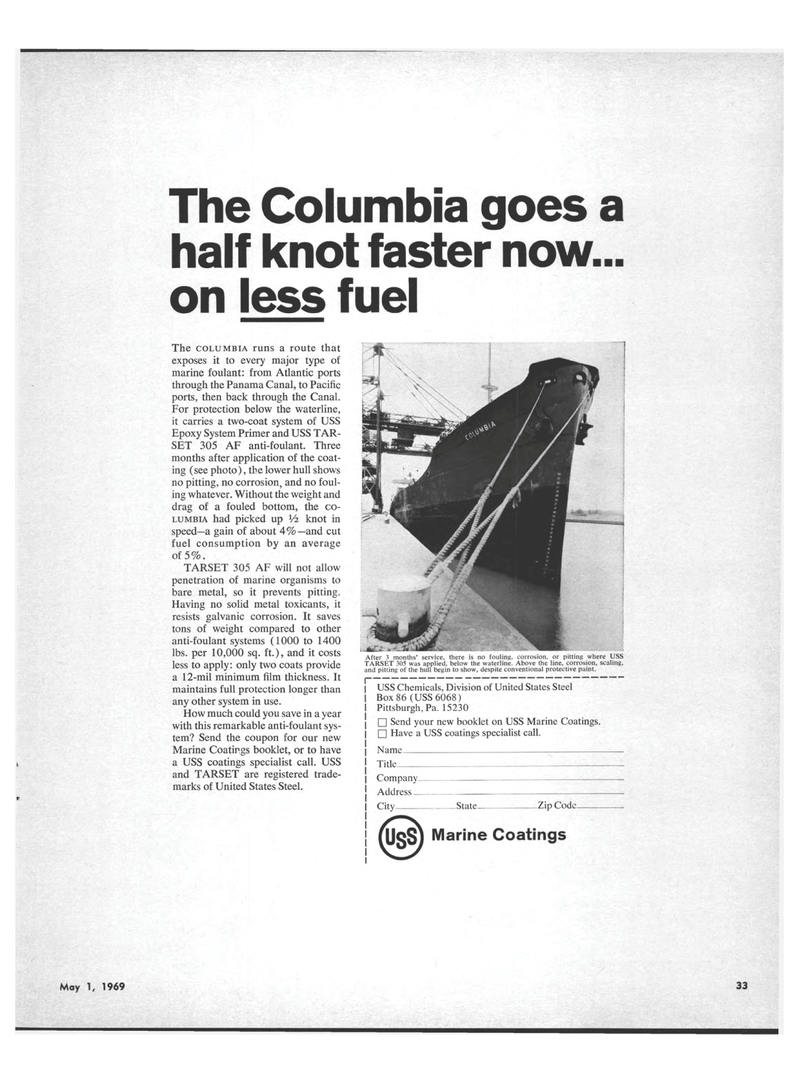

The Columbia goes a half knot faster now... on less fuel The COLUMBIA runs a route that exposes it to every major type of marine foulant: from Atlantic ports through the Panama Canal, to Pacific ports, then back through the Canal. For protection below the waterline, it carries a two-coat system of USS Epoxy System Primer and USS TAR-SET 305 AF anti-foulant. Three months after application of the coat-ing (see photo), the lower hull shows no pitting, no corrosion, and no foul-ing whatever. Without the weight and drag of a fouled bottom, the CO-LUMBIA had picked up Vi knot in speed?a gain of about 4%? and cut fuel consumption by an average of 5%. TARSET 305 AF will not allow penetration of marine organisms to bare metal, so it prevents pitting. Having no solid metal toxicants, it resists galvanic corrosion. It saves tons of weight compared to other anti-foulant systems (1000 to 1400 lbs. per 10,000 sq. ft.), and it costs less to apply: only two coats provide a 12-mil minimum film thickness. It maintains full protection longer than any other system in use. How much could you save in a year with this remarkable anti-foulant sys-tem? Send the coupon for our new Marine Coatings booklet, or to have a USS coatings specialist call. USS and TARSET are registered trade-marks of United States Steel. After 3 months' service, there is no fouling, corrosion, or pitting where USS TARSET 305 was applied, below the waterline. Above the line, corrosion, scaling, and pitting of the hull begin to show, despite conventional protective paint. USS Chemicals, Division of United States Steel Box 86 (USS 6068) I Pittsburgh, Pa. 15230 ? Send your new booklet on USS Marine Coatings. ? Have a USS coatings specialist call. Name ?? Title -? | Company Address City State Zip Code? Marine Coatings @

30

30

32

32