Page 21: of Maritime Reporter Magazine (May 15, 1969)

Read this page in Pdf, Flash or Html5 edition of May 15, 1969 Maritime Reporter Magazine

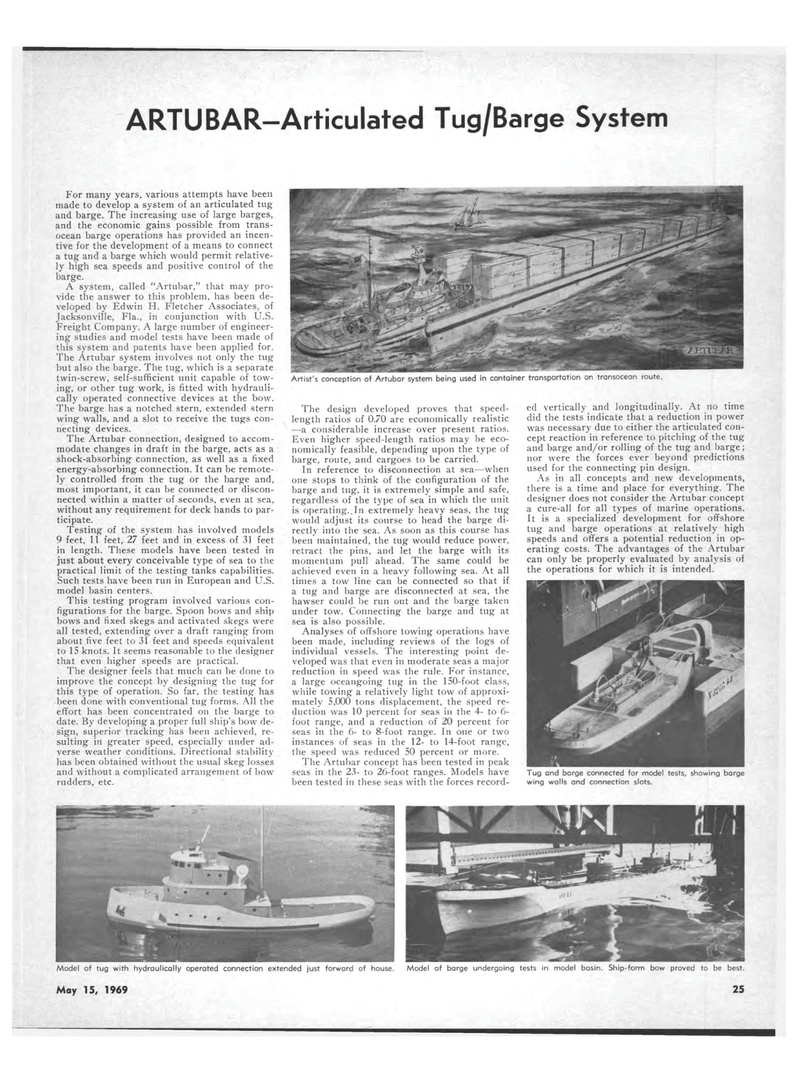

ARTUBAR-Articulated Tug/Barge System For many years, various attempts have been made to develop a system of an articulated tug and barge. The increasing use of large barges, and the economic gains possible from trans-ocean barge operations has provided an incen-tive for the development of a means to connect a tug and a barge which would permit relative-ly high sea speeds and positive control of the barge. A system, called "Artubar," that may pro-vide the answer to this problem, has been de-veloped by Edwin H. Fletcher Associates, of Jacksonville, Fla., in conjunction with U.S. Freight Company. A large number of engineer-ing studies and model tests have been made of this system and patents have been applied for. The Artubar system involves not only the tug but also the barge. The tug, which is a separate twin-screw, self-sufficient unit capable of tow-ing, or other tug work, is fitted with hydrauli-cally operated connective devices at the bow. The barge has a notched stern, extended stern wing walls, and a slot to receive the tugs con-necting devices. The Artubar connection, designed to accom-modate changes in draft in the barge, acts as a shock-absorbing connection, as well as a fixed energy-absorbing connection. It can be remote-ly controlled from the tug or the barge and, most important, it can be connected or discon-nected within a matter of seconds, even at sea, without any requirement for deck hands to par-ticipate. Testing of the system has involved models 9 feet, 11 feet, 27 feet and in excess of 31 feet in length. These models have been tested in just about every conceivable type of sea to the practical limit of the testing tanks capabilities. Such tests have been run in European and U.S. model basin centers. This testing program involved various con-figurations for the barge. Spoon bows and ship bows and fixed skegs and activated skegs were all tested, extending over a draft ranging from about five feet to 3l feet and speeds equivalent to 15 knots. It seems reasonable to the designer that even higher speeds are practical. The designer feels that much can be done to improve the concept by designing the tug for this type of operation. So far, the testing has been done with conventional tug forms. All the effort has been concentrated on the barge to date. By developing a proper full ship's bow de-sign, superior tracking has been achieved, re-sulting in greater speed, especially under ad-verse weather conditions. Directional stability has been obtained without the usual skeg losses and without a complicated arrangement of bow rudders, etc. The design developed proves that speed-length ratios of 0.70 are economically realistic ?a considerable increase over present ratios. Even higher speed-length ratios may be eco-nomically feasible, depending upon the type of barge, route, and cargoes to be carried. In reference to disconnection at sea?when one stops to think of the configuration of the barge and tug, it is extremely simple and safe, regardless of the type of sea in which the unit is operating..In extremely heavy seas, the tug would adjust its course to head the barge di-rectly into the sea. As soon as this course has been maintained, the tug would reduce power, retract the pins, and let the barge with its momentum pull ahead. The same could be achieved even in a heavy following sea. At all times a tow line can be connected so that if a tug and barge are disconnected at sea, the hawser could be run out and the barge taken under tow. Connecting the barge and tug at sea is also possible. Analyses of offshore towing operations have been made, including reviews of the logs of individual vessels. The interesting point de-veloped was that even in moderate seas a major reduction in speed was the rule. For instance, a large oceangoing tug in the 150-foot class, while towing a relatively light tow of approxi-mately 5,000 tons displacement, the speed re-duction was 10 percent for seas in the 4- to 6-foot range, and a reduction of 20 percent for seas in the 6- to 8-foot range. In one or two instances of seas in the 12- to 14-foot range, the speed was reduced 50 percent or more. The Artubar concept has been tested in peak seas in the 23- to 26-foot ranges. Models have been tested in these seas with the forces record-ed vertically and longitudinally. At no time did the tests indicate that a reduction in power was necessary due to either the articulated con-cept reaction in reference to pitching of the tug and barge and/or rolling of the tug and barge; nor were the forces ever beyond predictions used for the connecting pin design. As in all concepts and new developments, there is a time and place for everything. The designer does not consider the Artubar concept a cure-all for all types of marine operations. It is a specialized development for offshore tug and barge operations at relatively high speeds and offers a potential reduction in op-erating costs. The advantages of the Artubar can only be properly evaluated by analysis of the operations for which it is intended. Tug and barge connected for model tests, showing barge wing walls and connection slots. Model of tug with hydroulically operated connection extended just forward of house. Model of barge undergoing tests in model basin. Ship-form bow proved to be best. May 25, 1969 13

20

20

22

22