Page 48: of Maritime Reporter Magazine (June 1969)

Read this page in Pdf, Flash or Html5 edition of June 1969 Maritime Reporter Magazine

Billion Dollar Shipbuilding Contract

Awarded Litton By Navy For Nine LHAs

Artist's concept of the LHA which will be built at Litton's new Ingalls shipyard.

The U.S. Navy has awarded Lit- ton Industries a potential billion- dollar contract, the largest ship- building order ever received by one company, Ellis B. Gardner, senior vice-president in charge of Litton's

Marine Group, announced.

Under the contract Litton will produce the first of the Navy's gen- eral purpose, amphibious assault ships (designated LHA), a new- class of combatant vessel which will increase the readiness and ef- fectiveness of Navy and Marine

Corps amphibious forces.

Litton has received a fixed-price incentive contract in the potential amount of $1,012,500,000 for con- struction of nine LHA ships. The contract which was signed is for an increment of $113.9-million pro- viding funds for the first ship ($112,500,000) and long lead-time equipment for the second and third ships ($1,400,000). Construction of all nine ships is contingent upon continued Congressional approval of the program.

Designed by Litton's Advanced

Marine Technology division. El

Segundo, Calif., the LHA will be produced by Litton's Ingalls Ship- building division in a new $130- million mechanized ship manufac- turing facility in Pascagoula, Miss.

The new ship production plant, in- corporating the world's most ad- vanced marine production techno- logy, will produce the LHA's on an assembly-line basis using modu- lar construction techniques.

LHA is unique by many stand- ards, according to Capt. R. F.

Wilkinson, the Navy's LHA pro- ject manager. He noted that it will be the first combatant ship to be designed and manufactured under the new Department of Defense ac- quisition process, Concept Formu- lation/Contract Definition, where the entire construction contract is awarded to a single firm as a Total

Package Procurement.

R. R. Gunter, Litton LHA pro- gram manager, said the complex ship and the support systems were evolved together to insure the ship has the optimum amount of auto- mation at the least cost over its lifetime. The complex command, communication and control system for directing single or multi-ship assault was principally designed by

Litton's Data Systems division, which will continue its participa- tion in the project throughout the entire LHA production. "Further cost reductions will be realized by the assembly-line type of production possible in Litton's new 600-acre shipyard," Mr. Gard- ner said. The LHA will be the first naval vessels manufactured in Lit- ton's new shipyard where commer- cial ship production will begin in

December of this year.

These LHA's will be faster and more powerful than any modern amphibious ships now in the Navy and will perform a mission which now requires four different types of assault vessels. This "four-ship- in-one" capability offered by LHA will preserve the tactical integrity of combat units since the amphibi- ous landing force and their re- quired equipment (including com- bat cargo, tanks and trucks) will be carried in a single ship. LHA is similar to an aircraft carrier in size and appearance, being 820 feet long, with a 106-foot beam, full flight deck and side superstructure.

A large open well at the stern per- mits rapid entry and exit of large landing craft.

The general purpose amphibious assault ship offers troop comforts far surpassing those of World War

II troop carriers. Accommodations were designed to encourage high troop morale as well as fitness en route to combat. These include air conditioning, hot showers, ice cream bar, hobby shop and 40 closed circuit television units for movies, taped TV programs, brief- ings and training programs. Trop- ic-bound marines will have the benefit of working out each day in an acclimatization gymasium.

Steam will propel the amphibi- ous assault ship. Litton Industries chose geared steam turbines after determining the comparative life- cycle costs of operating the mam- moth ship.

An expandable flight deck will be incorporated on the LHA since it must be narrow enough to pass through the Panama Canal. At sea, a deck extension folds out to pro- vide a 12-foot-wide passage to star- board of the superstructure. Troops waiting to board helicopters will be marshalled on walkways and pas- sages just under the flight deck for protection and to screen them from activities on the flight deck, but still close enough for rapid debark- ation.

Newly Created Post

To Edward B. Colby

At GM Detroit Diesel

Edward B. Colby

C. W. Truxell, general manager of Detroit Diesel Engine Division,

General Motors Corporation, has announced the appointment of Ed- ward B. Colby to the newly created staff position of general manufac- turing manager.

In making the announcement,

Mr. Truxell stated, "This appoint- ment is being made to provide an expanded organization to help han- dle the problems associated with our explosive growth of today and to prepare for our continuing growth of tomorrow."

As general manufacturing man- ager, Mr. Colby will be responsible for coordinating the efforts of man- ufacturing, material control, pur- chasing, and reliability. Mr. Colby comes to Detroit Diesel from Ro- chester Products Division, where he was works manager.

Prior to his assignment at Ro- chester Products Division, he was with the Saginaw Steering Gear

Division, where his assignments in- cluded material and production control, labor relations, assistant chief engineer, and manager of sev- eral plants.

During World War II, Mr. Col- by served as a pilot with the U.S.

Army Air Force. Following his discharge as a Lieutenant in 1945, he returned to Saginaw where he became a co-op student at General

Motors Institute in Flint, Mich.

He was awarded a bachelor's de- gree in industrial engineering in 1950. In 1956 he received a Sloan

Fellowship to Massachusetts In- stitute of Technology, where he re- ceived a master of science degree in June, 1957.

Maritime Fruit Appoints

Myron A. Gelberg

Owners Representative

Maritime Fruit Carriers Com- pany Limited, a refrigerated ship- ping firm headquartered in Haifa,

Israel, has announced the appoint- ment of Myron A. Gelberg as own- er's representative.

In this capacity he will supervise the operations of Maritime Fruit

Carrier's regular liner service re- cently initiated between the East

Coast of the U.S. and Australia.

Mr. Gelberg has his office at Ches- ter, Blackburn and Roder, Inc., 1

Whitehall Street. New York, N.Y., general agents for the Maritime

Fruit firm.

Prior to joining Maritime, Mr.

Gelberg was traffic manager of the

Pacific Star Line. He is a graduate of the U.S. Merchant Marine Acad- emy, Kings Point, L.I.

KBBfeia; ..-.-,: ,.: •••HSMHI t- llWBHrWWlrer*^^^

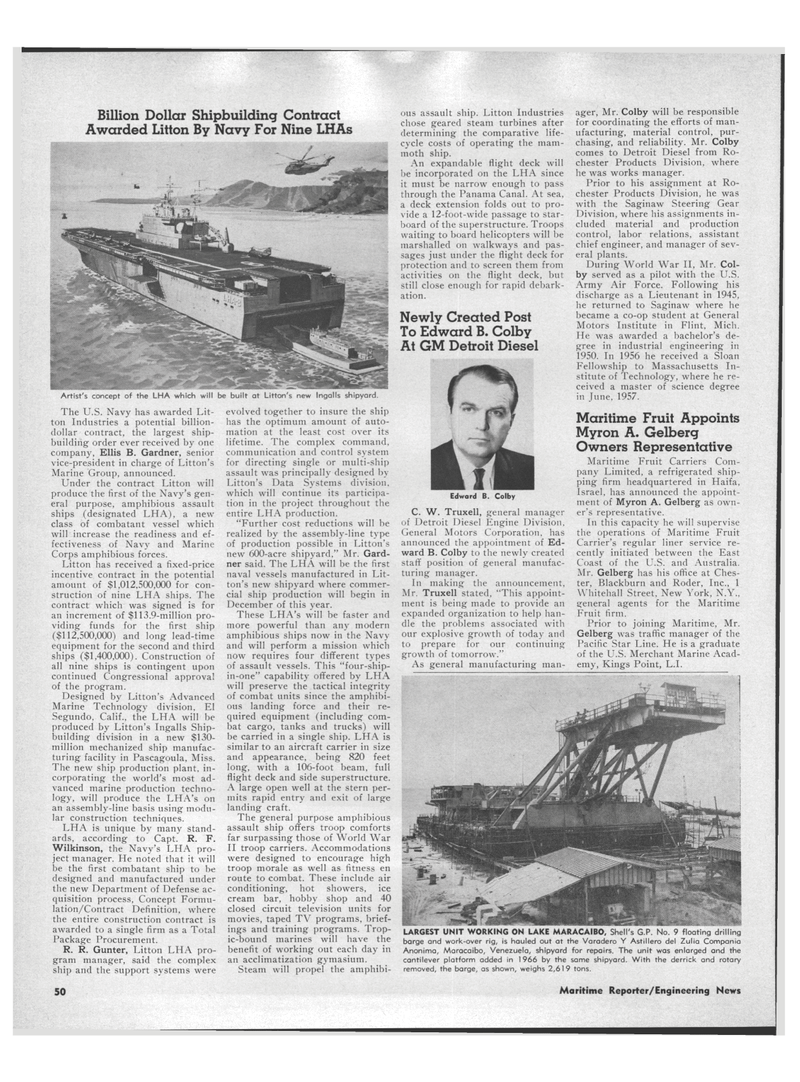

LARGEST UNIT WORKING ON LAKE MARACAIBO, Shell's G.P. No. 9 floating drilling barge and work-over rig, is hauled out at the Varadero Y Astillero del Zulia Compania

Anonima, Maracaibo, Venezuela, shipyard for repairs. The unit was enlarged and the cantilever platform added in 1966 by the same shipyard. With the derrick and rotary removed, the barge, as shown, weighs 2,619 tons. 50 Maritime Reporter/Engineering News

47

47

49

49