Page 47: of Maritime Reporter Magazine (June 15, 1969)

Read this page in Pdf, Flash or Html5 edition of June 15, 1969 Maritime Reporter Magazine

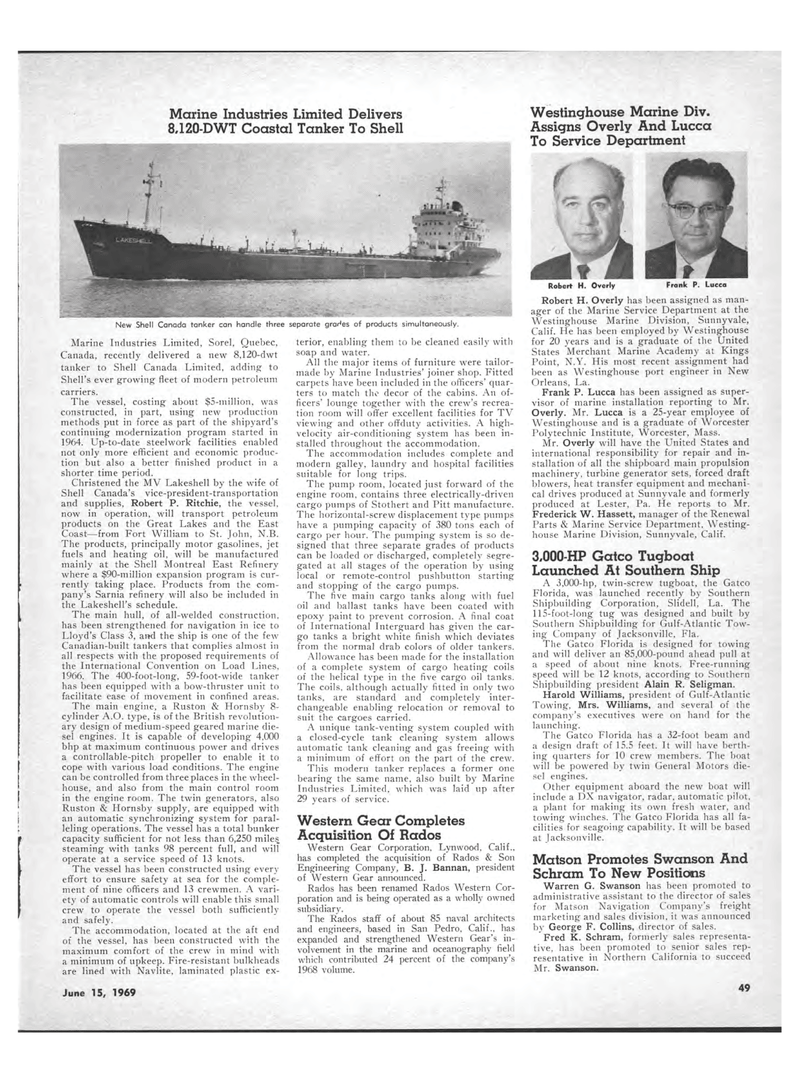

Marine Industries Limited Delivers 8,120-DWT Coastal Tanker To Shell New Shell Canada tanker can handle three separate graHes of products simultaneously. Marine Industries Limited, Sorel, Quebec, Canada, recently delivered a new 8,120-dwt tanker to Shell Canada Limited, adding to Shell's ever growing fleet of modern petroleum carriers. The vessel, costing about $5-million, was constructed, in part, using new production methods put in force as part of the shipyard's continuing modernization program started in 1964. Up-to-date steelwork facilities enabled not only more efficient and economic produc-tion but also a better finished product in a shorter time period. Christened the MV Lakeshell by the wife of Shell Canada's vice-president-transportation and supplies, Robert P. Ritchie, the vessel, now in operation, will transport petroleum products on the Great Lakes and the East Coast?from Fort William to St. John, N.B. The products, principally motor gasolines, jet fuels and heating oil, will be manufactured mainly at the Shell Montreal East Refinery where a $90-million expansion program is cur-rently taking place. Products from the com-pany's Sarnia refinery will also be included in the Lakeshell's schedule. The main hull, of all-welded construction, has been strengthened for navigation in ice to Lloyd's Class 3, and the ship is one of the few Canadian-built tankers that complies almost in all respects with the proposed requirements of the International Convention on Load Lines, 1966. The 400-foot-long, 59-foot-wide tanker has been equipped with a bow-thruster unit to facilitate ease of movement in confined areas. The main engine, a Ruston & Hornsby 8-cylinder A.O. type, is of the British revolution-ary design of medium-speed geared marine die-sel engines. It is capable of developing 4,000 bhp at maximum continuous power and drives a controllable-pitch propeller to enable it to cope with various load conditions. The engine can be controlled from three places in the wheel-house, and also from the main control room in the engine room. The twin generators, also Ruston & Hornsby supply, are equipped with an automatic synchronizing system for paral-leling operations. The vessel has a total bunker capacity sufficient for not less than 6,250 miles steaming with tanks 98 percent full, and will operate at a service speed of 13 knots. The vessel has been constructed using every effort to ensure safety at sea for the comple-ment of nine officers and 13 crewmen. A vari-ety of automatic controls will enable this small crew to operate the vessel both sufficiently and safely. The accommodation, located at the aft end of the vessel, has been constructed with the maximum comfort of the crew in mind with a minimum of upkeep. Fire-resistant bulkheads are lined with Navlite, laminated plastic ex-terior, enabling them to be cleaned easily with soap and water. All the major items of furniture were tailor-made by Marine Industries' joiner shop. Fitted carpets have been included in the officers' quar-ters to match the decor of the cabins. An of-ficers' lounge together with the crew's recrea-tion room will offer excellent facilities for TV viewing and other offduty activities. A high-velocity air-conditioning system has been in-stalled throughout the accommodation. The accommodation includes complete and modern galley, laundry and hospital facilities suitable for long trips. The pump room, located just forward of the engine room, contains three electrically-driven cargo pumps of Stothert and Pitt manufacture. The horizontal-screw displacement type pumps have a pumping capacity of 380 tons each of cargo per hour. The pumping system is so de-signed that three separate grades of products can be loaded or discharged, completely segre-gated at all stages of the operation by using local or remote-control pushbutton starting and stopping of the cargo pumps. The five main cargo tanks along with fuel oil and ballast tanks have been coated with epoxy paint to prevent corrosion. A final coat of International Interguard has given the car-go tanks a bright white finish which deviates from the normal drab colors of older tankers. Allowance has been made for the installation of a complete system of cargo heating coils of the helical type in the five cargo oil tanks. The coils, although actually fitted in only two tanks, are standard and completely inter-changeable enabling relocation or removal to suit the cargoes carried. A unique tank-venting system coupled with a closed-cycle tank cleaning system allows automatic tank cleaning and gas freeing with a minimum of effort on the part of the crew. This modern tanker replaces a former one bearing the same name, also built by Marine Industries Limited, which was laid up after 29 years of service. Western Gear Completes Acquisition Of Rados Western Gear Corporation, Lynwood, Calif., has completed the acquisition of Rados & Son Engineering Company, B. J. Bannan, president of Western Gear announced. Rados has been renamed Rados Western Cor-poration and is being operated as a wholly owned subsidiary. The Rados staff of about 85 naval architects and engineers, based in San Pedro, Calif., has expanded and strengthened Western Gear's in-volvement in the marine and oceanography field which contributed 24 percent of the company's 1968 volume. Robert H. Overly has been assigned as man-ager of the Marine Service Department at the Westinghouse Marine Division, Sunnyvale, Calif. He has been employed by Westinghouse for 20 years and is a graduate of the United States Merchant Marine Academy at Kings Point, N.Y. His most recent assignment had been as Westinghouse port engineer in New Orleans, La. Frank P. Lucca has been assigned as super-visor of marine installation reporting to Mr. Overly. Mr. Lucca is a 25-year employee of Westinghouse and is a graduate of Worcester Polytechnic Institute, Worcester, Mass. Mr. Overly will have the United States and international responsibility for repair and in-stallation of all the shipboard main propulsion machinery, turbine generator sets, forced draft blowers, heat transfer equipment and mechani-cal drives produced at Sunnyvale and formerly produced at Lester, Pa. He reports to Mr. Frederick W. Hassett, manager of the Renewal Parts & Marine Service Department. Westing-house Marine Division, Sunnyvale, Calif. 3,000-HP Gatco Tugboat Launched At Southern Ship A 3,000-hp, twin-screw tugboat, the Gatco Florida, was launched recently by Southern Shipbuilding Corporation, Slidell, La. The 115-foot-long tug was designed and built by Southern Shipbuilding for Gulf-Atlantic Tow-ing Company of Jacksonville, Fla. The Gatco Florida is designed for towing and will deliver an 85,000-pound ahead pull at a speed of about nine knots. Free-running speed will be 12 knots, according to Southern Shipbuilding president Alain R. Seligman. Harold Williams, president of Gulf-Atlantic Towing. Mrs. Williams, and several of the company's executives were on hand for the launching. The Gatco Florida has a 32-foot beam and a design draft of 15.5 feet. It will have berth-ing quarters for 10 crew members. The boat will be powered by twin General Motors die-sel engines. Other equipment aboard the new boat will include a DX navigator, radar, automatic pilot, a plant for making its own fresh water, and towing winches. The Gatco Florida has all fa-cilities for seagoing capability. It will be based at Jacksonville. Matson Promotes Swanson And Schram To New Positions Warren G. Swanson has been promoted to administrative assistant to the director of sales for Matson Navigation Company's freight marketing and sales division, it was announced by George F. Collins, director of sales. Fred K. Schram, formerly sales representa-tive, has been promoted to senior sales rep-resentative in Northern California to succeed Mr. Swanson. Westinghouse Marine Div. Assigns Overly And Lucca To Service Department Robert H. Overly Frank P. Lucca June 15, 1969 49

46

46

48

48