Page 12: of Maritime Reporter Magazine (July 1969)

Read this page in Pdf, Flash or Html5 edition of July 1969 Maritime Reporter Magazine

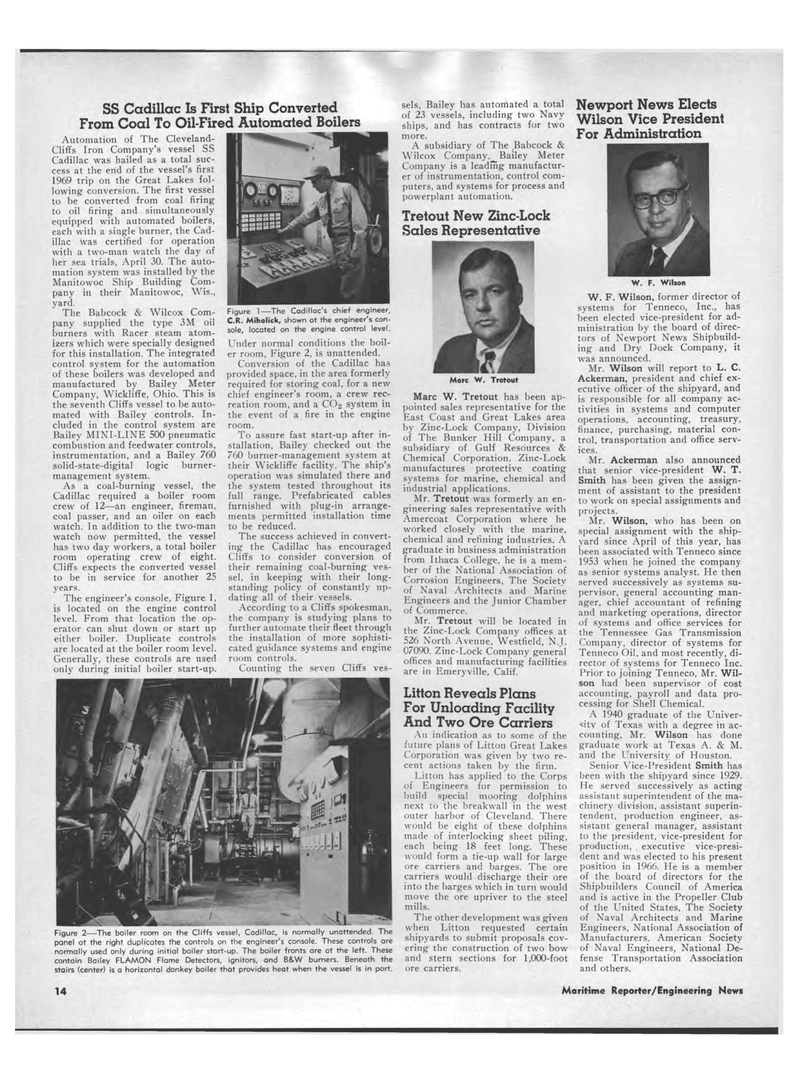

SS Cadillac Is First Ship Converted From Coal To Oil-Fired Automated Boilers Automation of The Cleveland-Cliffs Iron Company's vessel SS Cadillac was hailed as a total suc-cess at the end of the vessel's first 1969 trip on the Great Lakes fol-lowing conversion. The first vessel to be converted from coal firing to oil firing and simultaneously equipped with automated boilers, each with a single burner, the Cad-illac was certified for operation with a two-man watch the day of her sea trials, April 30. The auto-mation system was installed by the Manitowoc Ship Building Com-pany in their Manitowoc, Wis., yard. The Babcock & Wilcox Com-pany supplied the type 3M oil burners with Racer steam atom-izers which were specially designed for this installation. The integrated control system for the automation of these boilers was developed and manufactured by Bailey Meter Company, Wickliffe, Ohio. This is the seventh Cliffs vessel to be auto-mated with Bailey controls. In-cluded in the control system are Bailey MINI-LINE 500 pneumatic combustion and feedwater controls, instrumentation, and a Bailey 760 solid-state-digital logic burner-management system. As a coal-burning vessel, the Cadillac required a boiler room crew of 12?an engineer, fireman, coal passer, and an oiler on each watch. In addition to the two-man watch now permitted, the vessel has two day workers, a total boiler room operating crew of eight. Cliffs expects the converted vessel to be in service for another 25 years. The engineer's console, Figure 1, is located on the engine control level. From that location the op-erator can shut down or start up either boiler. Duplicate controls are located at the boiler room level. Generally, these controls are used only during initial boiler start-up. Figure 1?The Cadillac's chief engineer, C.R. Miholick, shown at the engineer's con-sole, located on the engine control level. Under normal conditions the boil-er room, Figure 2, is unattended. Conversion of the Cadillac has provided space, in the area formerly required for storing coal, for a new chief engineer's room, a crew rec-reation room, and a CO2 system in the event of a fire in the engine room. To assure fast start-up after in-stallation, Bailey checked out the 760 burner-management system at their Wickliffe facility. The ship's operation was simulated there and the system tested throughout its full range. Prefabricated cables furnished with plug-in arrange-ments permitted installation time to be reduced. The success achieved in convert-ing the Cadillac has encouraged Cliffs to consider conversion of their remaining coal-burning ves-sel, in keeping with their long-standing policy of constantly up-dating all of their vessels. According to a Cliffs spokesman, the company is studying plans to further automate their fleet through the installation of more sophisti-cated guidance systems and engine room controls. Counting the seven Cliffs ves-sels, Bailey has automated a total of 23 vessels, including two Navy ships, and has contracts for two more. A subsidiary of The Babcock & Wilcox Company, Bailey Meter Company is a leading manufactur-er of instrumentation, control com-puters, and systems for process and powerplant automation. Tretout New Zinc-Lock Sales Representative Marc W. Tretout Marc W. Tretout has been ap-pointed sales representative for the East Coast and Great Lakes area by Zinc-Lock Company, Division of The Bunker Hill Company, a subsidiary of Gulf Resources & Chemical Corporation. Zinc-Lock manufactures protective coating systems for marine, chemical and industrial applications. Mr. Tretout was formerly an en-gineering sales representative with Amercoat Corporation where he worked closely with the marine, chemical and refining industries. A graduate in business administration from Ithaca College, he is a mem-ber of the National Association of Corrosion Engineers, The Society of Naval Architects and Marine Engineers and the Junior Chamber of Commerce. Mr. Tretout will be located in the Zinc-Lock Company offices at 526 North Avenue, Westfield, N.j. 07090. Zinc-Lock Company general offices and manufacturing facilities are in Emeryville, Calif. Litton Reveals Plans For Unloading Facility And Two Ore Carriers An indication as to some of the future plans of Litton Great Lakes Corporation was given by two re-cent actions taken by the firm. Litton has applied to the Corps of Engineers for permission to build special mooring dolphins next to the breakwall in the west outer harbor of Cleveland. There would be eight of these dolphins made of interlocking sheet piling, each being 18 feet long. These would form a tie-up wall for large ore carriers and barges. The ore carriers would discharge their ore into the barges which in turn would move the ore upriver to the steel mills. The other development was given when Litton requested certain shipyards to submit proposals cov-ering the construction of two bow and stern sections for 1,000-foot ore carriers. Newport News Elects Wilson Vice President For Administration m-' ^m s Wj W. F. Wilson W. F. Wilson, former director of systems for Tenneco, Inc., has been elected vice-president for ad-ministration by the board of direc-tors of Newport News Shipbuild-ing and Dry Dock Company, it was announced. Mr. Wilson will report to L. C. Ackerman, president and chief ex-ecutive officer of the shipyard, and is responsible for all company ac-tivities in systems and computer operations, accounting, treasury, finance, purchasing, material con-trol, transportation and office serv-ices. Mr. Ackerman also announced that senior vice-president W. T. Smith has been given the assign-ment of assistant to the president to work on special assignments and projects. Mr. Wilson, who has been on special assignment with the ship-yard since April of this year, has been associated with Tenneco since 1953 when he joined the company as senior systems analyst. He then served successively as systems su-pervisor, general accounting man-ager, chief accountant of refining and marketing operations, director of systems and office services for the Tennessee Gas Transmission Company, director of systems for Tenneco Oil, and most recently, di-rector of systems for Tenneco Inc. Prior to joining Tenneco, Mr. Wil-son had been supervisor of cost accounting, payroll and data pro-cessing for Shell Chemical. A 1940 graduate of the Univer-sity of Texas with a degree in ac-counting, Mr. Wilson has done graduate work at Texas A. & M. and the University of Houston. Senior Vice-President Smith has been with the shipyard since 1929. He served successively as acting assistant superintendent of the ma-chinery division, assistant superin-tendent, production engineer, as-sistant general manager, assistant to the president, vice-president for production, executive vice-presi-dent and was elected to his present position in 1966. He is a member of the board of directors for the Shipbuilders Council of America and is active in the Propeller Club of the United States, The Society of Naval Architects and Marine Engineers, National Association of Manufacturers, American Society of Naval Engineers, National De-fense Transportation Association and others. Figure 2?The boiler room on the Cliffs vessel, Cadillac, is normally unattended. The panel at the right duplicates the controls on the engineer's console. These controls are normally used only during initial boiler start-up. The boiler fronts are at the left. These contain Bailey FLAMON Flame Detectors, ignitors, and B&W burners. Beneath the stairs (center) is a horizontal donkey boiler that provides heat when the vessel is in port. 10 Maritime Reporter/Engineering News

11

11

13

13