Page 22: of Maritime Reporter Magazine (July 15, 1969)

Read this page in Pdf, Flash or Html5 edition of July 15, 1969 Maritime Reporter Magazine

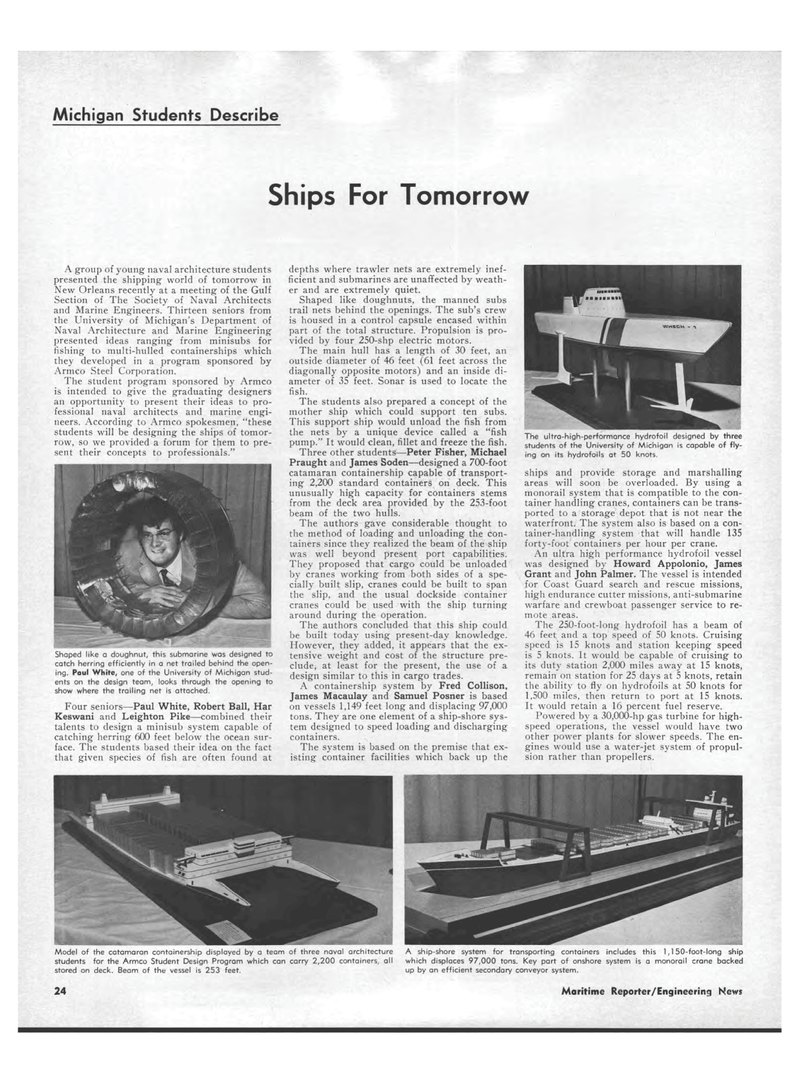

Michigan Students Describe Ships For Tomorrow Model of the catamaran containership displayed by a team of three naval architecture students for the Armco Student Design Program which can carry 2,200 containers, all stored on deck. Beam of the vessel is 253 feet. A ship-shore system for transporting containers includes this 1,150-foot-long ship which displaces 97,000 tons. Key part of onshore system is a monorail crane backed up by an efficient secondary conveyor system. depths where trawler nets are extremely inef-ficient and submarines are unaffected by weath-er and are extremely quiet. Shaped like doughnuts, the manned subs trail nets behind the openings. The sub's crew is housed in a control capsule encased within part of the total structure. Propulsion is pro-vided by four 250-shp electric motors. The main hull has a length of 30 feet, an outside diameter of 46 feet (61 feet across the diagonally opposite motors) and an inside di-ameter of 35 feet. Sonar is used to locate the fish. The students also prepared a concept of the mother ship which could support ten subs. This support ship would unload the fish from the nets by a unique device called a "fish pump." It would clean, fillet and freeze the fish. Three other students?Peter Fisher, Michael Praught and James Soden?designed a 700-foot catamaran containership capable of transport-ing 2,200 standard containers on deck. This unusually high capacity for containers stems from the deck area provided by the 253-foot beam of the two hulls. The authors gave considerable thought to the method of loading and unloading the con-tainers since they realized the beam of the ship was well beyond present port capabilities. They proposed that cargo could be unloaded by cranes working from both sides of a spe-cially built slip, cranes could be built to span the slip, and the usual dockside container cranes could be used with the ship turning around during the operation. The authors concluded that this ship could be built today using present-day knowledge. However, they added, it appears that the ex-tensive weight and cost of the structure pre-clude, at least for the present, the use of a design similar to this in cargo trades. A containership system by Fred Collison, James Macaulay and Samuel Posner is based on vessels 1,149 feet long and displacing 97,000 tons. They are one element of a ship-shore sys-tem designed to speed loading and discharging containers. The system is based on the premise that ex-isting container facilities which back up the The ultra-high-performance hydrofoil designed by three students of the University of Michigan is capable of fly-ing on its hydrofoils at 50 knots. ships and provide storage and marshalling areas will soon be overloaded. By using a monorail system that is compatible to the con-tainer handling cranes, containers can be trans-ported to a storage depot that is not near the waterfront. The system also is based on a con-tainer-handling system that will handle 135 forty-foot containers per hour per crane. An ultra high performance hydrofoil vessel was designed by Howard Appolonio, James Grant and John Palmer. The vessel is intended for Coast Guard search and rescue missions, high endurance cutter missions, anti-submarine warfare and crewboat passenger service to re-mote areas. The 250-foot-long hydrofoil has a beam of 46 feet and a top speed of 50 knots. Cruising speed is 15 knots and station keeping speed is 5 knots. It would be capable of cruising to its duty station 2,000 miles away at 15 knots, remain on station for 25 days at 5 knots, retain the ability to fly on hydrofoils at 50 knots for 1,500 miles, then return to port at 15 knots. It would retain a 16 percent fuel reserve. Powered by a 30,000-hp gas turbine for high-speed operations, the vessel would have two other power plants for slower speeds. The en-gines would use a water-jet system of propul-sion rather than propellers. A group of young naval architecture students presented the shipping world of tomorrow in New Orleans recently at a meeting of the Gulf Section of The Society of Naval Architects and Marine Engineers. Thirteen seniors from the University of Michigan's Department of Naval Architecture and Marine Engineering presented ideas ranging from minisubs for fishing to multi-hulled containerships which they developed in a program sponsored by Armco Steel Corporation. The student program sponsored by Armco is intended to give the graduating designers an opportunity to present their ideas to pro-fessional naval architects and marine engi-neers. According to Armco spokesmen, "these students will be designing the ships of tomor-row, so we provided a forum for them to pre-sent their concepts to professionals." Shaped like a doughnut, this submarine was designed to catch herring efficiently in a net trailed behind the open-ing. Paul White, one of the University of Michigan stud-ents on the design team, looks through the opening to show where the trailing net is attached. Four seniors?Paul White, Robert Ball, Har Keswani and Leighton Pike?combined their talents to design a minisub system capable of catching herring 600 feet below the ocean sur-face. The students based their idea on the fact that given species of fish are often found at 24 Maritime Reporter/Engineering News

21

21

23

23