Page 39: of Maritime Reporter Magazine (July 15, 1969)

Read this page in Pdf, Flash or Html5 edition of July 15, 1969 Maritime Reporter Magazine

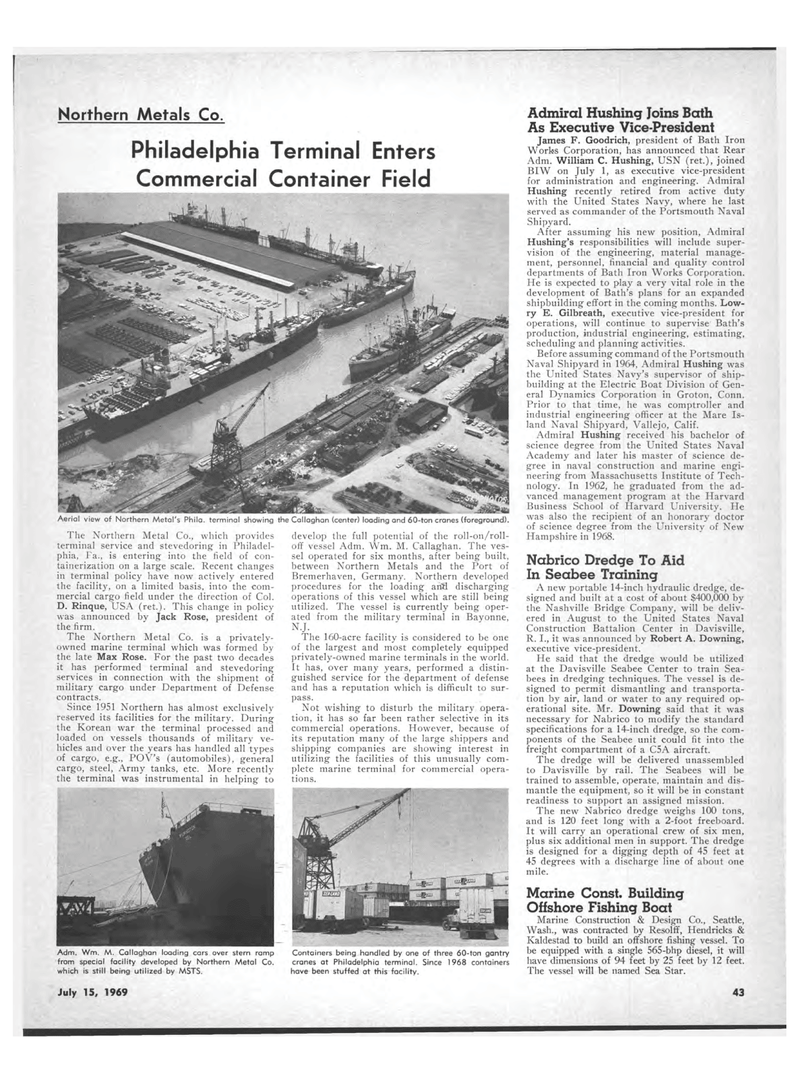

Admiral Hushing Joins Bath As Executive Vice-President James F. Goodrich, president of Bath Iron Works Corporation, has announced that Rear Adm. William C. Hushing, USN (ret.), joined BIW on July 1, as executive vice-president for administration and engineering. Admiral Hushing recently retired from active duty with the United States Navy, where he last served as commander of the Portsmouth Naval Shipyard. After assuming his new position, Admiral Hushing's responsibilities will include super-vision of the engineering, material manage-ment, personnel, financial and quality control departments of Bath Iron Works Corporation. He is expected to play a very vital role in the development of Bath's plans for an expanded shipbuilding effort in the coming months. Low-ry E. Gilbreath, executive vice-president for operations, will continue to supervise Bath's production, industrial engineering, estimating, scheduling and planning activities. Before assuming command of the Portsmouth Naval Shipyard in 1964, Admiral Hushing was the United States Navy's supervisor of ship-building at the Electric Boat Division of Gen-eral Dynamics Corporation in Groton, Conn. Prior to that time, he was comptroller and industrial engineering officer at the Mare Is-land Naval Shipyard, Vallejo, Calif. Admiral Hushing received his bachelor of science degree from the United States Naval Academy and later his master of science de-gree in naval construction and marine engi-neering from Massachusetts Institute of Tech-nology. In 1962, he graduated from the ad-vanced management program at the Harvard Business School of Harvard University. He was also the recipient of an honorary doctor of science degree from the University of New Hampshire in 1968. Nabrico Dredge To Aid In Seabee Training A new portable 14-inch hydraulic dredge, de-signed and built at a cost of about $400,000 by the Nashville Bridge Company, will be deliv-ered in August to the United States Naval Construction Battalion Center in Davisville, R. I., it was announced by Robert A. Downing, executive vice-president. He said that the dredge would be utilized at the Davisville Seabee Center to train Sea-bees in dredging techniques. The vessel is de-signed to permit dismantling and transporta-tion by air, land or water to any required op-erational site. Mr. Downing said that it was necessary for Nabrico to modify the standard specifications for a 14-inch dredge, so the com-ponents of the Seabee unit could fit into the freight compartment of a C5A aircraft. The dredge will be delivered unassembled to Davisville by rail. The Seabees will be trained to assemble, operate, maintain and dis-mantle the equipment, so it will be in constant readiness to support an assigned mission. The new Nabrico dredge weighs 100 tons, and is 120 feet long with a 2-foot freeboard. It will carry an operational crew of six men, plus six additional men in support. The dredge is designed for a digging depth of 45 feet at 45 degrees with a discharge line of about one mile. Marine Const. Building Offshore Fishing Boat Marine Construction & Design Co., Seattle, Wash., was contracted by Resolff, Hendricks & Kaldestad to build an offshore fishing vessel. To be equipped with a single 565-bhp diesel, it will have dimensions of 94 feet by 25 feet by 12 feet. The vessel will be named Sea Star. Northern Metals Co. Philadelphia Terminal Enters Commercial Container Field Aerial view of Northern Metal's Phila. terminal showing the Callaghan (center) loading and 60-ton cranes (foreground). The Northern Metal Co., which provides terminal service and stevedoring in Philadel-phia, Fa., is entering into the field of con-tainerization on a large scale. Recent changes in terminal policy have now actively entered the facility, on a limited basis, into the com-mercial cargo field under the direction of Col. D. Rinque, USA (ret.). This change in policy was announced by Jack Rose, president of the firm. The Northern Metal Co. is a privately-owned marine terminal which was formed by the late Max Rose. For the past two decades it has performed terminal and stevedoring services in connection with the shipment of military cargo under Department of Defense contracts. Since 1951 Northern has almost exclusively reserved its facilities for the military. During the Korean war the terminal processed and loaded on vessels thousands of military ve-hicles and over the years has handled all types of cargo, e.g., PO\ s (automobiles), general cargo, steel, Army tanks, etc. More recently the terminal was instrumental in helping to develop the full potential of the roll-on/roll-off vessel Adm. Wm. M. Callaghan. The ves-sel operated for six months, after being built, between Northern Metals and the Port of Bremerhaven, Germany. Northern developed procedures for the loading arifl discharging operations of this vessel which are still being utilized- The vessel is currently being oper-ated from the military terminal in Bayonne, N.J. The 160-acre facility is considered to be one of the largest and most completely equipped privately-owned marine terminals in the world. It has, over many years, performed a distin-guished service for the department of defense and has a reputation which is difficult to sur-pass. Not wishing to disturb the military opera-tion, it has so far been rather selective in its commercial operations. However, because of its reputation many of the large shippers and shipping companies are showing interest in utilizing the facilities of this unusually com-plete marine terminal for commercial opera-tions. Containers being handled by one of three 60-ton gantry cranes at Philadelphia terminal. Since 1968 containers have been stuffed at this facility. Adm. Wm. M. Callaghan loading cars over stern ramp from special facility developed by Northern Metal Co. which is still being utilized by MSTS. July 43, 1969 13

38

38

40

40