Page 37: of Maritime Reporter Magazine (August 1969)

Read this page in Pdf, Flash or Html5 edition of August 1969 Maritime Reporter Magazine

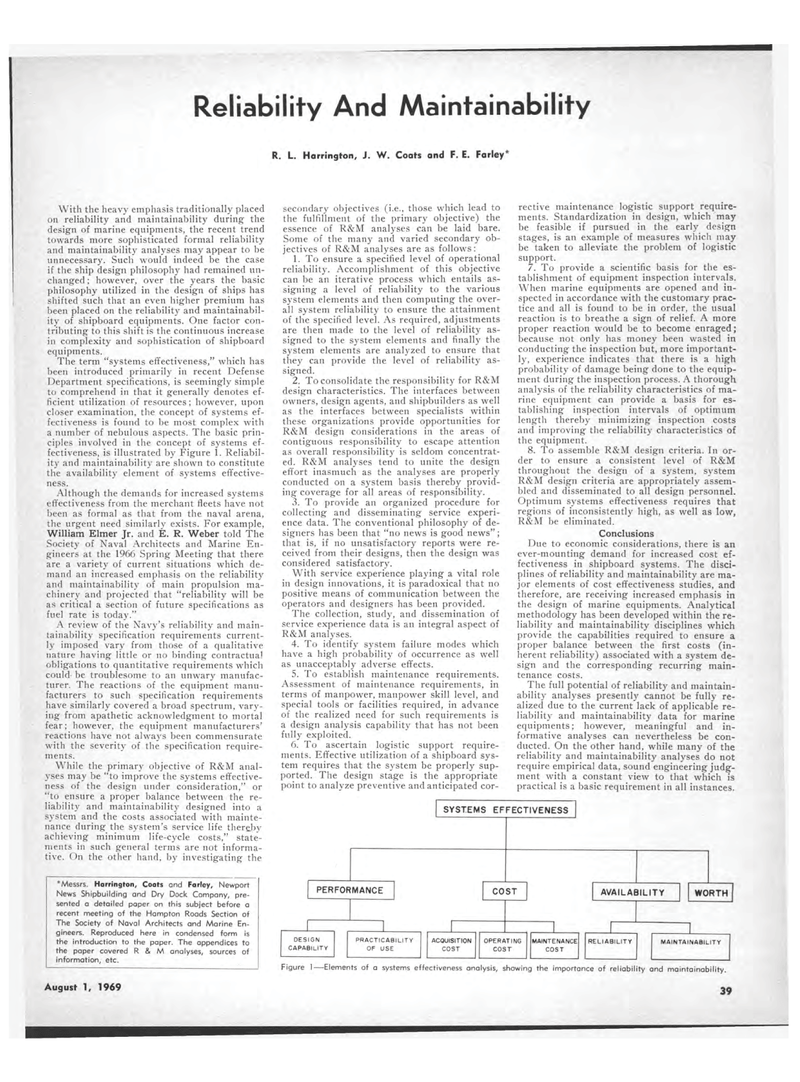

Reliability And Maintainability R. L. Harrington, J. W. Coats and F. E. Farley* With the heavy emphasis traditionally placed on reliability and maintainability during the design of marine equipments, the recent trend towards more sophisticated formal reliability and maintainability analyses may appear to be unnecessary. Such would indeed be the case if the ship design philosophy had remained un-changed ; however, over the years the basic philosophy utilized in the design of ships has shifted such that an even higher premium has been placed on the reliability and maintainabil-ity of shipboard equipments. One factor con-tributing to this shift is the continuous increase in complexity and sophistication of shipboard equipments. The term "systems effectiveness," which has been introduced primarily in recent Defense Department specifications, is seemingly simple to comprehend in that it generally denotes ef-ficient utilization of resources; however, upon closer examination, the concept of systems ef-fectiveness is found to be most complex with a number of nebulous aspects. The basic prin-ciples involved in the concept of systems ef-fectiveness, is illustrated by Figure 1. Reliabil-ity and maintainability are shown to constitute the availability element of systems effective-ness. Although the demands for increased systems effectiveness from the merchant fleets have not been as formal as that from the naval arena, the urgent need similarly exists. For example, William Elmer Jr. and E. R. Weber told The Society of Naval Architects and Marine En-gineers at the 1966 Spring Meeting that there are a variety of current situations which de-mand an increased emphasis on the reliability and maintainability of main propulsion ma-chinery and projected that "reliability will be as critical a section of future specifications as fuel rate is today." A review of the Navy's reliability and main-tainability specification requirements current-ly imposed vary from those of a qualitative nature having little or no binding contractual obligations to quantitative requirements which could be troublesome to an unwary manufac-turer. The reactions of the equipment manu-facturers to such specification requirements have similarly covered a broad spectrum, vary-ing from apathetic acknowledgment to mortal fear; however, the equipment manufacturers' reactions have not always been commensurate with the severity of the specification require-ments. While the primary objective of R&M anal-yses may be "to improve the systems effective-ness of the design under consideration," or secondary objectives (i.e., those which lead to the fulfillment of the primary objective) the essence of R&M analyses can be laid bare. Some of the many and varied secondary ob-jectives of R&M analyses are as follows: 1. To ensure a specified level of operational reliability. Accomplishment of this objective can be an iterative process which entails as-signing a level of reliability to the various system elements and then computing the over-all system reliability to ensure the attainment of the specified level. As required, adjustments are then made to the level of reliability as-signed to the system elements and finally the system elements are analyzed to ensure that they can provide the level of reliability as-signed. 2. To consolidate the responsibility for R&M design characteristics. The interfaces between owners, design agents, and shipbuilders as well as the interfaces between specialists within these organizations provide opportunities for R&M design considerations in the areas of contiguous responsibility to escape attention as overall responsibility is seldom concentrat-ed. R&M analyses tend to unite the design effort inasmuch as the analyses are properly conducted on a system basis thereby provid-ing coverage for all areas of responsibility. 3. To provide an organized procedure for collecting and disseminating service experi-ence data. The conventional philosophy of de-signers has been that "no news is good news"; that is, if no unsatisfactory reports were re-ceived from their designs, then the design was considered satisfactory. With service experience playing a vital role in design innovations, it is paradoxical that no positive means of communication between the operators and designers has been provided. The collection, study, and dissemination of service experience data is an integral aspect of R&M analyses. 4. To identify system failure modes which have a high probability of occurrence as well as unacceptably adverse effects. 5. To establish maintenance requirements. Assessment of maintenance requirements, in terms of manpower, manpower skill level, and special tools or facilities required, in advance of the realized need for such requirements is a design analysis capability that has not been fully exploited. 6. To ascertain logistic support require-ments. Effective utilization of a shipboard sys-tem requires that the system be properly sup-ported. The design stage is the appropriate point to analyze preventive and anticipated cor-rective maintenance logistic support require-ments. Standardization in design, which may be feasible if pursued in the early design stages, is an example of measures which may be taken to alleviate the problem of logistic support. 7. To provide a scientific basis for the es-tablishment of equipment inspection intervals. When marine equipments are opened and in-spected in accordance with the customary prac-tice and all is found to be in order, the usual reaction is to breathe a sign of relief. A more proper reaction would be to become enraged; because not only has money been wasted in conducting the inspection but, more important-ly, experience indicates that there is a high probability of damage being done to the equip-ment during the inspection process. A thorough analysis of the reliability characteristics of ma-rine equipment can provide a basis for es-tablishing inspection intervals of optimum length thereby minimizing inspection costs and improving the reliability characteristics of the equipment. 8. To assemble R&M design criteria. In or-der to ensure a consistent level of R&M throughout the design of a system, system R&M design criteria are appropriately assem-bled and disseminated to all design personnel. Optimum systems effectiveness requires that regions of inconsistently high, as well as low, R&M be eliminated. Conclusions Due to economic considerations, there is an ever-mounting demand for increased cost ef-fectiveness in shipboard systems. The disci-plines of reliability and maintainability are ma-jor elements of cost effectiveness studies, and therefore, are receiving increased emphasis in the design of marine equipments. Analytical methodology has been developed within the re-liability and maintainability disciplines which provide the capabilities required to ensure a proper balance between the first costs (in-herent reliability) associated with a system de-sign and the corresponding recurring main-tenance costs. The full potential of reliability and maintain-ability analyses presently cannot be fully re-alized due to the current lack of applicable re-liability and maintainability data for marine equipments; however, meaningful and in-formative analyses can nevertheless be con-ducted. On the other hand, while many of the reliability and maintainability analyses do not require empirical data, sound engineering judg-ment with a constant view to that which is practical is a basic requirement in all instances. August 1, 1969 39

36

36

38

38