Page 44: of Maritime Reporter Magazine (August 1969)

Read this page in Pdf, Flash or Html5 edition of August 1969 Maritime Reporter Magazine

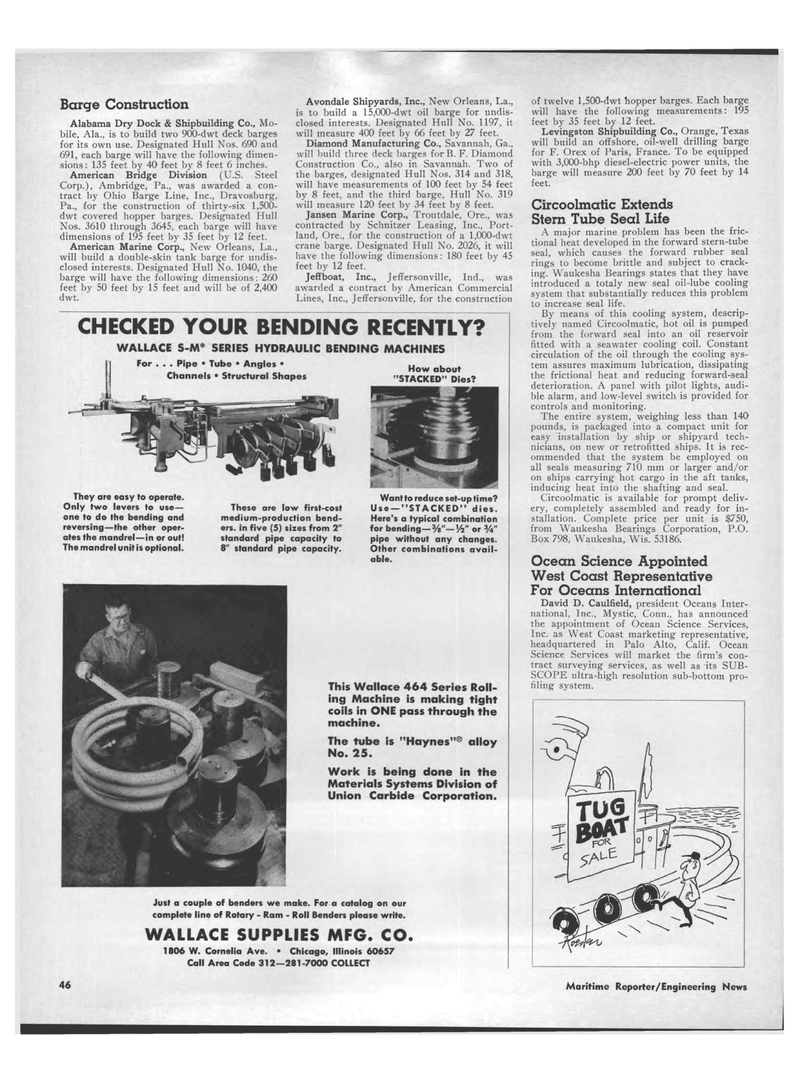

Barge Construction Alabama Dry Dock & Shipbuilding Co., Mo-bile, Ala., is to build two 900-dwt deck barges for its own use. Designated Hull Nos. 690 and 691, each barge will have the following dimen-sions < 135 feet by 40 feet by 8 feet 6 inches. American Bridge Division (U.S. Steel Corp.), Ambridge, Pa., was awarded a con-tract by Ohio Barge Line, Inc., Dravosburg, Pa., for the construction of thirty-six 1,500-dwt covered hopper barges. Designated Hull Nos. 3610 through 3645, each barge will have dimensions of 195 feet by 35 feet by 12 feet. American Marine Corp., New Orleans, La., will build a double-skin tank barge for undis-closed interests. Designated Hull No. 1040, the barge will have the following dimensions: 260 feet by 50 feet by 15 feet and will be of 2,400 dwt. Avondale Shipyards, Inc., New Orleans, La., is to build a 15,000-dwt oil barge for undis-closed interests. Designated Hull No. 1197, it will measure 400 feet by 66 feet by 27 feet. Diamond Manufacturing Co., Savannah, Ga., will build three deck barges forB. F. Diamond Construction Co., also in Savannah. Two of the barges, designated Hull Nos. 314 and 318, will have measurements of 100 feet by 54 feet by 8 feet, and the third barge, Hull No. 319 will measure 120 feet by 34 feet by 8 feet. Jansen Marine Corp., Troutdale, Ore., was contracted by Schnitzer Leasing, Inc., Port-land, Ore., for the construction of a 1,000-dwt crane barge. Designated Hull No. 2026, it will have the following dimensions: 180 feet by 45 feet by 12 feet. Jeffboat, Inc., Jeffersonville, Ind., was awarded a contract by American Commercial Lines, Inc., Jeffersonville, for the construction How about "STACKED" Dies? of twelve 1,500-dwt hopper barges. Each barge will have the following measurements: 195 feet by 35 feet by 12 feet. Levingston Shipbuilding Co., Orange, Texas will build an offshore, oil-well drilling barge for F. Orex of Paris, France. To be equipped with 3,000-bhp diesel-electric power units, the barge will measure 200 feet by 70 feet by 14 feet. Circoolmatic Extends Stern Tube Seal Life A major marine problem has been the fric-tional heat developed in the forward stern-tube seal, which causes the forward rubber seal rings to become brittle and subject to crack-ing. Waukesha Bearings states that they have introduced a totaly new seal oil-lube cooling system that substantially reduces this problem to increase seal life. By means of this cooling system, descrip-tively named Circoolmatic, hot oil is pumped from the forward seal into an oil reservoir fitted with a seawater cooling coil. Constant circulation of the oil through the cooling sys-tem assures maximum lubrication, dissipating the frictional heat and reducing forward-seal deterioration. A panel with pilot lights, audi-ble alarm, and low-level switch is provided for controls and monitoring. The entire system, weighing less than 140 pounds, is packaged into a compact unit for easy "installation by ship or shipyard tech-nicians, on new or retrofitted ships. It is rec-ommended that the system be employed on all seals measuring 710 mm or larger and/or on ships carrying hot cargo in the aft tanks, inducing heat into the shafting and seal. Circoolmatic is available for prompt deliv-ery, completely assembled and ready for in-stallation. Complete price per unit is $750, from Waukesha Bearings Corporation, P.O. Box 798, Waukesha, Wis. 53186. Ocean Science Appointed West Coast Representative For Oceans International David D. Caulfield, president Oceans Inter-national, Inc., Mystic, Conn., has announced the appointment of Ocean Science Services, Inc. as West Coast marketing representative, headquartered in Palo Alto, Calif. Ocean Science Services will market the firm's con-tract surveying services, as well as its SUB-SCOPE ultra-high resolution sub-bottom pro-filing system. CHECKED YOUR BENDING RECENTLY? WALLACE S-M* SERIES HYDRAULIC BENDING MACHINES They are easy to operate. Only two levers to use? one to do the bending and reversing?the other oper-ates the mandrel?in or out! The mandrel unit is optional. These are low first-cost medium-production bend-ers. In five (5) sizes from 2" standard pipe capacity to 8" standard pipe capacity. Want to reduce set-up time? Use ?"STACKED" dies. Here's a typical combination for bending?Vt"?W or 3A" pipe without any changes. Other combinations avail-able. This Wallace 464 Series Roll-ing Machine is making tight coils in ONE pass through the machine. The tube is "Haynes"® alloy No. 25. Work is being done in the Materials Systems Division of Union Carbide Corporation. Just a couple of benders we make. For a catalog on our complete line of Rotary - Ram - Roll Benders please write. WALLACE SUPPLIES MFG. CO. 1806 W. Cornelia Ave. ? Chicago, Illinois 60657 Call Area Code 312-281-7000 COLLECT For . . . Pipe ? Tube ? Angles ? Channels ? Structural Shapes 46 Maritime Reporter/Engineering News

43

43

45

45