Page 6: of Maritime Reporter Magazine (April 1970)

Read this page in Pdf, Flash or Html5 edition of April 1970 Maritime Reporter Magazine

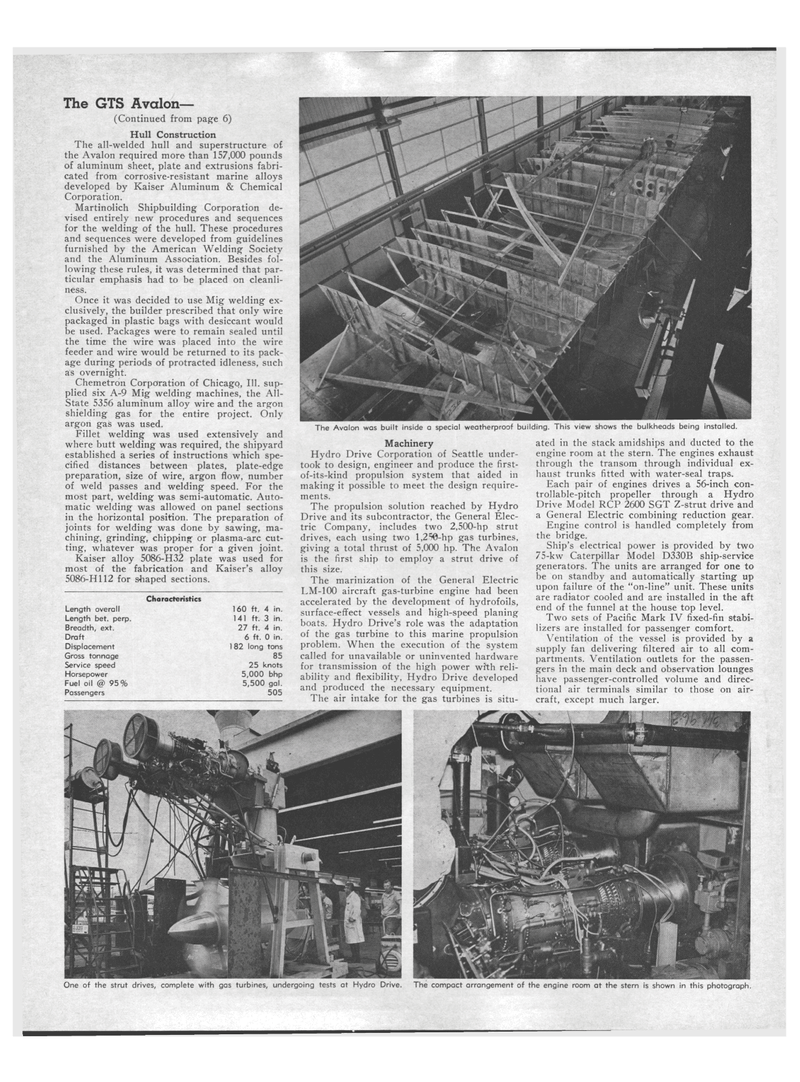

One of the strut drives, complete with gos turbines, undergoing tests at Hydro Drive. The compact arrangement of the engine room at the stern is shown in this photograph.

The GTS Avalon— (Continued from page 6)

Hull Construction

The all-welded hull and superstructure of. the Avalon required more than 157,000 pounds of aluminum sheet, plate and extrusions fabri- cated from corrosive-resistant marine alloys developed by Kaiser Aluminum & Chemical

Corporation.

Martinolich Shipbuilding Corporation de- vised entirely new procedures and sequences for the welding of the hull. These procedures and sequences were developed from guidelines furnished by the American Welding Society and the Aluminum Association. Besides fol- lowing these rules, it was determined that par- ticular emphasis had to be placed on cleanli- ness.

Once it was decided to use Mig welding ex- clusively, the builder prescribed that only wire packaged in plastic bags with desiccant would be used. Packages were to remain sealed until the time the wire was placed into the wire feeder and wire would be returned to its pack- age during periods of protracted idleness, such as overnight.

Chemetron Corporation of Chicago, 111. sup- plied six A-9 Mig welding machines, the All-

State 5356 aluminum alloy wire and the argon shielding gas for the entire project. Only argon gas was used.

Fillet welding was used extensively and where butt welding was required, the shipyard established a series of instructions which spe- cified distances between plates, plate-edge preparation, size of wire, argon flow, number of weld passes and welding speed. For the most part, welding was semi-automatic. Auto- matic welding was allowed on panel sections in the horizontal position. The preparation of joints for welding was done by sawing, ma- chining, grinding, chipping or plasma-arc cut- ting, whatever was proper for a given joint.

Kaiser alloy 5086-H32 plate was used for most of the fabrication and Kaiser's alloy 5086-H112 for shaped sections.

Length overall

Length bet. perp.

Breadth, ext.

Draft

Displacement

Gross tonnage

Service speed

Horsepower

Fuel oil @ 95%

Passengers

Characteristics 160 ft. 4 in. 141 ft. 3 in. 27 ft. 4 in. 6 ft. 0 in. 182 long tons 85 25 knots 5,000 bhp 5,500 gal. 505

Machinery

Hydro Drive Corporation of Seattle under- took to design, engineer and produce the first- of-its-kind propulsion system that aided in making it possible to meet the design require- ments.

The propulsion solution reached by Hydro

Drive and its subcontractor, the General Elec- tric Company, includes two 2,500-hp strut drives, each using two l,25G-hp gas turbines, giving a total thrust of 5,000 hp. The Avalon is the first ship to employ a strut drive of this size.

The marinization of the General Electric

LM-100 aircraft gas-turbine engine had been accelerated by the development of hydrofoils, surface-effect vessels and high-speed planing boats. Hydro Drive's role was the adaptation of the gas turbine to this marine propulsion problem. When the execution of the system called for unavailable or uninvented hardware for transmission of the high power with reli- ability and flexibility, Hydro Drive developed and produced the necessary equipment.

The air intake for the gas turbines is situ- ated in the stack amidships and ducted to the engine room at the stern. The engines exhaust through the transom through individual ex- haust trunks fitted with water-seal traps.

Each pair of engines drives a 56-inch con- trollable-pitch propeller through a Hydro

Drive Model RCP 2600 SGT Z-strut drive and a General Electric combining reduction gear.

Engine control is handled completely from the bridge.

Ship's electrical power is provided by two 75-kw Caterpillar Model D330B ship-service generators. The units are arranged for one to be on standby and automatically starting up upon failure of the "on-line" unit. These units are radiator cooled and are installed in the aft end of the funnel at the house top level.

Two sets of Pacific Mark IV fixed-fin stabi- lizers are installed for passenger comfort.

Ventilation of the vessel is provided by a supply fan delivering filtered air to all com- partments. Ventilation outlets for the passen- gers in the main deck and observation lounges have passenger-controlled volume and direc- tional air terminals similar to those on air- craft, except much larger.

The Avalon was built inside a special weatherproof building. This view shows the bulkheads being installed.

5

5

7

7