Page 10: of Maritime Reporter Magazine (April 1971)

Read this page in Pdf, Flash or Html5 edition of April 1971 Maritime Reporter Magazine

American Ship Building Summer Program On

Names Gordon Stafford Transportation Systems

AmShip Div. President At M.I.T. August 16-27

Massachusetts Institute of Tech- nology has announced a special two-week summer program on

Analysis of Transportation Sys- tems, which Professors A.S. Lang,

E.G. Frankel, M.L. Manheim and

R.W. Simpson will be offering Au- gust 16 through August 27, 1971.

This special summer program presents the basic concepts and techniques of transportation sys- tems analysis and engineering.

Problems of policy, planning, de- sign, and operations will be treat- ed in an integrated manner. The perspective will be multi-modal, with treatment of problems in all modes of transportation, as well as intermodal systems.

Basic concepts and techniques will be covered in the first week.

In the second week, case studies will illustrate the application of these concepts and techniques to specific problem areas. Each of the two weeks may be taken separate- ly, or they may be taken as a two- week sequence.

For further information, please write to: Director of the Summer

Session, Room E19-356, M.I.T.,

Cambridge, Mass. 02139.

Gordon Stafford

Gordon Stafford has been named president of the AmShip Division of The American Ship Building

Co., it was announced by George

M. Steinbrenner III, chairman and chief executive officer. Mr. Staf- ford succeeds Walter J. Knapp, who has headed the division since its formation nearly three years ago.

Mr. Stafford, one of the more popular men in Great Lakes ma- rine circles, has been president of the BIOGEST Division, the cor- poration's marine technology and pollution control arm. Prior to that, he served as vice president, sales. As president of the AmShip

Division, Mr. Stafford will head shipbuilding and repair operations at the company's yards in Lorain,

Toledo and Chicago.

He began his career with Ameri- can Ship as a storeroom boy in the old Cleveland yard after graduat- ing from John Marshall High

School in 1937. He quickly rose to the position of foreman in the mold loft before being transferred to New Orleans as superintendent for Delta Ship Building Co., a war- time operation staffed by Ameri- can Ship personnel. There he par- ticipated in the construction of 188

Liberty ships, coal colliers and tankers.

After the war, Mr. Stafford filled a variety of supervisory as- signments for American Ship in both Toledo and Lorain before be- coming manager of the Lorain yard in 1954. Three years later he was promoted to assistant to the vice president of operations, and in 1963 was promoted to sales man- ager. In 1967, Mr. Stafford was named vice president, sales, and a year ago, president of the BIO-

GEST Division.

A veteran of 34 years with the company, Mr. Stafford is continu- ing the family shipbuilding tradi- tion started by his late father,

Charles N. Stafford, who first join- ed American Ship as a cabinetmak- er in 1910, and remained with the firm for over half a century.

Marine Construction

To Build 75-Foot Tug

Puget Sound Freight Lines, Seat- tle, Wash., has ordered a 75-foot tug from Marine Construction & Design

Co., Seattle. The vessel will be pow- ered by a 1,125-hp diesel.

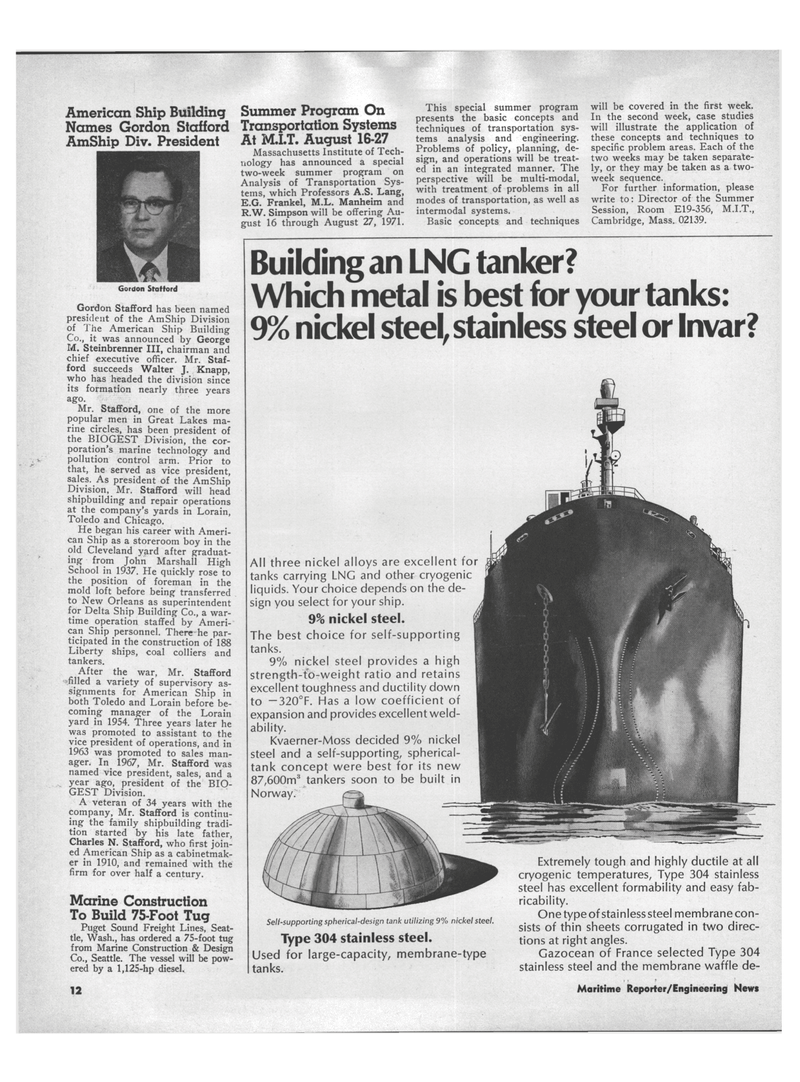

Building an LNG tanker?

Which metal is best for your tanks: 9% nickel steel, stainless steel or Invar?

All three nickel alloys are excellent for tanks carrying LNG and other cryogenic liquids. Your choice depends on the de- sign you select for your ship. 9% nickel steel.

The best choice for self-supporting tanks. 9% nickel steel provides a high strength-to-weight ratio and retains excellent toughness and ductility down to —320°F. Has a low coefficient of expansion and provides excellent weld- ability.

Kvaerner-Moss decided 9% nickel steel and a self-supporting, spherical- tank concept were best for its new 87,600m3 tankers soon to be built in

Norway.

Self-supporting spherical-design tank utilizing 9% nickel steel.

Type 304 stainless steel.

Used for large-capacity, membrane-type tanks.

Extremely tough and highly ductile at all cryogenic temperatures, Type 304 stainless steel has excellent formability and easy fab- ricability.

One type of stainless steel membrane con- sists of thin sheets corrugated in two direc- tions at right angles.

Gazocean of France selected Type 304 stainless steel and the membrane waffle de- 12 Maritime Reporter/Engineering News

9

9

11

11