Page 9: of Maritime Reporter Magazine (May 1971)

Read this page in Pdf, Flash or Html5 edition of May 1971 Maritime Reporter Magazine

MV FALCON LADY— (Continued from page 9)

Normally, both engines run in the same di- rection, and are operated from the bridge.

When required, one engine can run ahead, one astern, by engaging the clutches to move the ship ahead or astern in maneuvering, operated at the local station. The remote controls were supplied by WABCO and the mountings by

Honeywell.

Auxiliary Machinery

A Maxim waste-heat boiler, Model MFT 4000-32, utilizing the heat from the engines' exhaust can supply 5,000 pounds per hour of steam at 50 psi.

An Aqua-Chem flash-type evaporator, with a capacity of 8,000 gallons per day, utilizes the steam from the waste-heat boiler to provide potable and make-up fresh water.

A Foster Wheeler packaged marine boiler,

Type AGP, with Monowall-Waterwall con- struction is installed to provide steam for tank cleaning. It is fitted with a Coen Fyr-Utilipak packaged steam-atomizing oil burner and au- tomatic combustion controls. This boiler is rated at 70,000 pounds per hour at 600 psi.

Ship's service electric power is supplied by two Caterpillar, Model-D398B, turbo-charged, air-starting, marine diesel engines, rated at 795 bhp at 1,200 rpm, driving EM-700-series, 500- kw alternators. Emergency electric power is handled by one Caterpillar, Model D334, turbo- charged, battery-starting, marine diesel en- gine, rated at 200 bhp at 1,800 rpm, driving an

EM alternator, rated at 150 kw.

The deck machinery includes a Clarke-Chap- man anchor windlass with two vertical wild- cats and two vertical winch drums above deck.

It is driven by a steam reciprocating engine located under the deck. The Falcon Lady is also equipped with steam-driven, automatic - tensioning mooring winches. The steering gear is of the four-ram, electro-hydraulic type.

Cargo System

The cargo system is subdivided into five groups of tanks in order to handle the split cargoes that MSC ships are required to trans- port. There is no central pump room—cargo pumping is handled by five deep-well pumps with the drive units mounted on the deck.

The deep-well cargo pumps, supplied by

Worthington, are self-priming, three-stage, vertical turbine pumps, rated at 5,000-gpm each against a head of 334 feet when operating at 1,760 rpm. They are driven by Worthington steam turbines through Philadelphia Gear

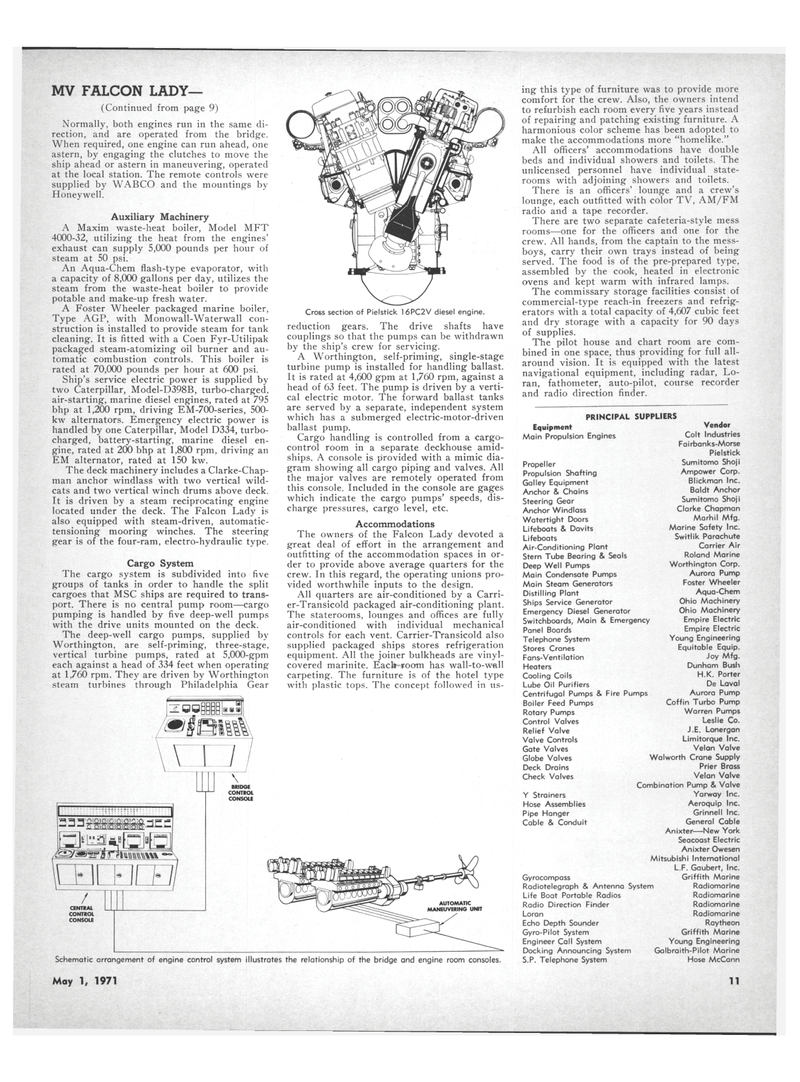

Cross section of Pielstick 16PC2V diesel engine. reduction gears. The drive shafts have couplings so that the pumps can be withdrawn by the ship's crew for servicing.

A Worthington, self-priming, single-stage turbine pump is installed for handling ballast.

It is rated at 4,600 gpm at 1,760 rpm, against a head of 63 feet. The pump is driven by a verti- cal electric motor. The forward ballast tanks are served by a separate, independent system which has a submerged electric-motor-driven ballast pump.

Cargo handling is controlled from a cargo- control room in a separate deckhouse amid- ships. A console is pirovided with a mimic dia- gram showing all cargo piping and valves. All the major valves are remotely operated from this console. Included in the console are gages which indicate the cargo pumps' speeds, dis- charge pressures, cargo level, etc.

Accommodations

The owners of the Falcon Lady devoted a great deal of effort in the arrangement and outfitting of the accommodation spaces in or- der to provide above average quarters for the crew. In this regard, the operating unions pro- vided worthwhile inputs to the design.

All quarters are air-conditioned by a Carri- er-Transicold packaged air-conditioning plant.

The staterooms, lounges and offices are fully air-conditioned with individual mechanical controls for each vent. Carrier-Transicold also supplied packaged ships stores refrigeration equipment. All the joiner bulkheads are vinyl- covered marinite. Eacb-room has wall-to-wall carpeting. The furniture is of the hotel type with plastic tops. The concept followed in us- ing this type of furniture was to provide more comfort for the crew. Also, the owners intend to refurbish each room every five years instead of repairing and patching existing furniture. A harmonious color scheme has been adopted to make the accommodations more "homelike."

All officers' accommodations have double beds and individual showers and toilets. The unlicensed personnel have individual state- rooms with adjoining showers and toilets.

There is an officers' lounge and a crew's lounge, each outfitted with color TV, AM/FM radio and a tape recorder.

There are two separate cafeteria-style mess rooms—one for the officers and one for the crew. All hands, from the captain to the mess- boys, carry their own trays instead of being served. The food is of the pre-prepared type, assembled by the cook, heated in electronic ovens and kept warm with infrared lamps.

The commissary storage facilities consist of commercial-type reach-in freezers and refrig- erators with a total capacity of 4,607 cubic feet and dry storage with a capacity for 90 days of supplies.

The pilot house and chart room are com- bined in one space, thus providing for full all- around vision. It is equipped with the latest navigational equipment, including radar, Lo- ran, fathometer, auto-pilot, course recorder and radio direction finder.

PRINCIPAL SUPPLIERS

Equipment Vendor

Main Propulsion Engines Colt Industries

Fairbanks-Morse

Pielstick

Propeller Sumitomo Shoji

Propulsion Shafting Ampower Corp.

Galley Equipment Blickman Inc.

Anchor & Chains Baldt Anchor

Steering Gear Sumitomo Shoji

Anchor Windlass Clarke Chapman

Watertight Doors Marhil Mfg.

Lifeboats & Davits Marine Safety Inc.

Lifeboats Switlik Parachute

Air-Conditioning Plant Carrier Air

Stern Tube Bearing & Seals Roland Marine

Deep Well Pumps Worthington Corp.

Main Condensate Pumps Aurora Pump

Main Steam Generators Foster Wheeler

Distilling Plant Aqua-Chem

Ships Service Generator Ohio Machinery

Emergency Diesel Generator Ohio Machinery

Switchboards, Main & Emergency Empire Electric

Panel Boards Empire Electric

Telephone System Young Engineering

Stores Cranes Equitable Equip.

Fans-Ventilation Joy Mfg.

Heaters Dunham Bush

Cooling Coils H.K. Porter

Lube Oil Purifiers De Laval

Centrifugal Pumps & Fire Pumps Aurora Pump

Boiler Feed Pumps Coffin Turbo Pump

Rotary Pumps Warren Pumps

Control Valves Leslie Co.

Relief Valve J.E. Lonergan

Valve Controls Limitorque Inc.

Gate Valves Velan Valve

Globe Valves Walworth Crane Supply

Deck Drains Prier Brass

Check Valves Velan Valve

Combination Pump & Valve

Y Strainers Yarway Inc.

Hose Assemblies Aeroquip Inc.

Pipe Hanger Grinnell Inc.

Cable & Conduit General Cable

Anixter—New York

Seacoast Electric

Anixter Owesen

Mitsubishi International

L.F. Gaubert, Inc.

Gyrocompass Griffith Marine

Radiotelegraph & Antenna System Radiomarine

Life Boat Portable Radios Radiomarine

Radio Direction Finder Radiomarine

Loran Radiomarine

Echo Depth Sounder Raytheon

Gyro-Pilot System Griffith Marine

Engineer Call System Young Engineering

Docking Announcing System Galbraith-Pilot Marine

S.P. Telephone System Hose McCann 11

Schematic arrangement of engine control system illustrates the relationship of the bridge and engine room consoles.

May 1, 1971

AUTOMATIC

MANEUVERING UNIT

8

8

10

10