Page 5: of Maritime Reporter Magazine (May 1971)

Read this page in Pdf, Flash or Html5 edition of May 1971 Maritime Reporter Magazine

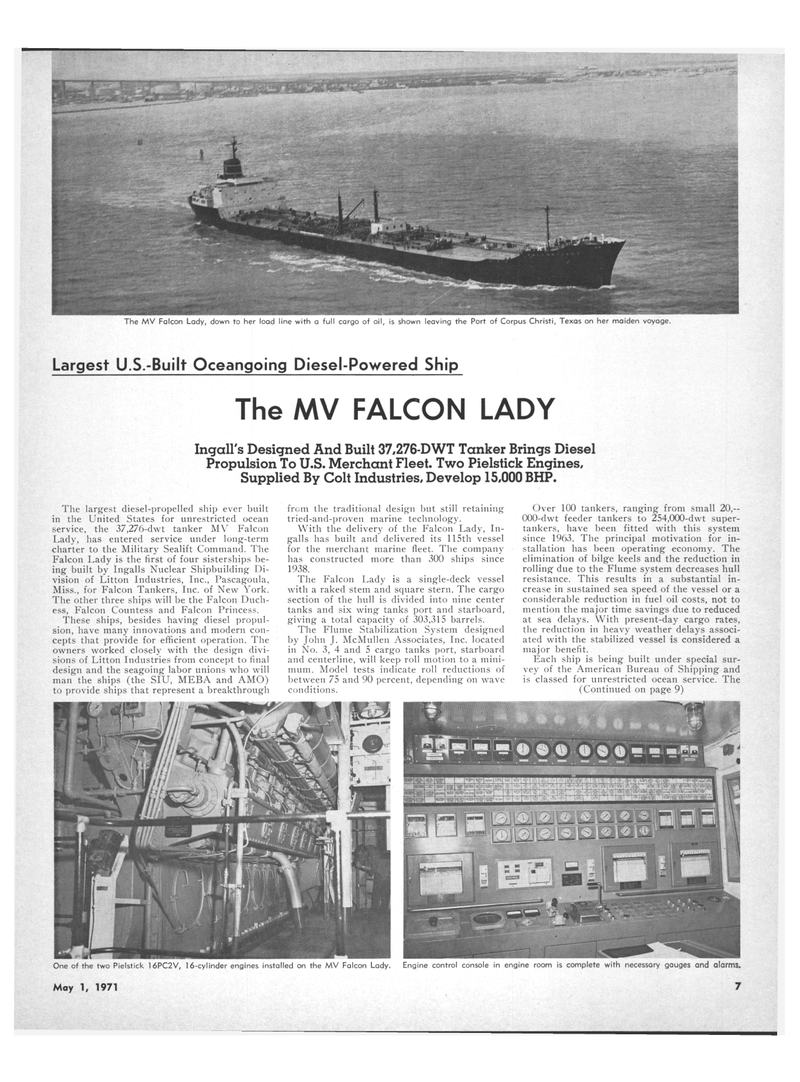

The MV Falcon Lady, down to her load line with a full cargo of oil, is shown leaving the Port of Corpus Christi, Texas on her maiden voyage

Largest U.S.-Built Oceangoing Diesel-Powered Ship

The MV FALCON LADY

Ingall's Designed And Built 37,276-DWT Tanker Brings Diesel

Propulsion To U.S. Merchant Fleet. Two Pielstick Engines,

Supplied By Colt Industries, Develop 15,000 BHP.

The largest diesel-propelled ship ever built in the United States for unrestricted ocean service, the 37,276-dwt tanker MV Falcon

Lady, has entered service under long-term charter to the Military Sealift Command. The

Falcon Lady is the first of four sisterships be- ing built by Ingalls Nuclear Shipbuilding Di- vision of Litton Industries, Inc., Pascagoula,

Miss., for Falcon Tankers, Inc. of New York.

The other three ships will be the Falcon Duch- ess, Falcon Countess and Falcon Princess.

These ships, besides having diesel propul- sion, have many innovations and modern con- cepts that provide for efficient operation. The owners worked closely with the design divi- sions of Litton Industries from concept to final design and the seagoing labor unions who will man the ships (the SIU, MEBA and AMO) to provide ships that represent a breakthrough from the traditional design but still retaining tried-and-proven marine technology.

With the delivery of the Falcon Lady, In- galls has built and delivered its 115th vessel for the merchant marine fleet. The company has constructed more than 300 ships since 1938.

The Falcon Lady is a single-deck vessel with a raked stem and square stern. The cargo section of the hull is divided into nine center tanks and six wing tanks port and starboard, giving a total capacity of 303,315 barrels.

The Flume Stabilization System designed by John J. McMullen Associates, Inc. located in No. 3, 4 and 5 cargo tanks port, starboard and centerline, will keep roll motion to a mini- mum. Model tests indicate roll reductions of between 75 and 90 percent, depending on wave conditions.

Over 100 tankers, ranging from small 20,— 000-dwt feeder tankers to 254,000-dwt super- tankers, have been fitted with this system since 1963. The principal motivation for in- stallation has been operating economy. The elimination of bilge keels and the reduction in rolling due to the Flume system decreases hull resistance. This results in a substantial in- crease in sustained sea speed of the vessel or a considerable reduction in fuel oil costs, not to mention the major time savings due to reduced at sea delays. With present-day cargo rates, the reduction in heavy weather delays associ- ated with the stabilized vessel is considered a major benefit.

Each ship is being built under special sur- vey of the American Bureau of Shipping and is classed for unrestricted ocean service. The (Continued on page 9)

One of the two Pielstick 1 6PC2V, 16-cylinder engines installed on the MV Falcon Lady. Engine control console in engine room is complete with necessary gauges and alarms.

May 1, 1971 7

4

4

6

6