Page 32: of Maritime Reporter Magazine (August 1971)

Read this page in Pdf, Flash or Html5 edition of August 1971 Maritime Reporter Magazine

Intergard Tank Coaling Systems can save you as much as 35% in material costs.

Their high-volume solids are the reason why.

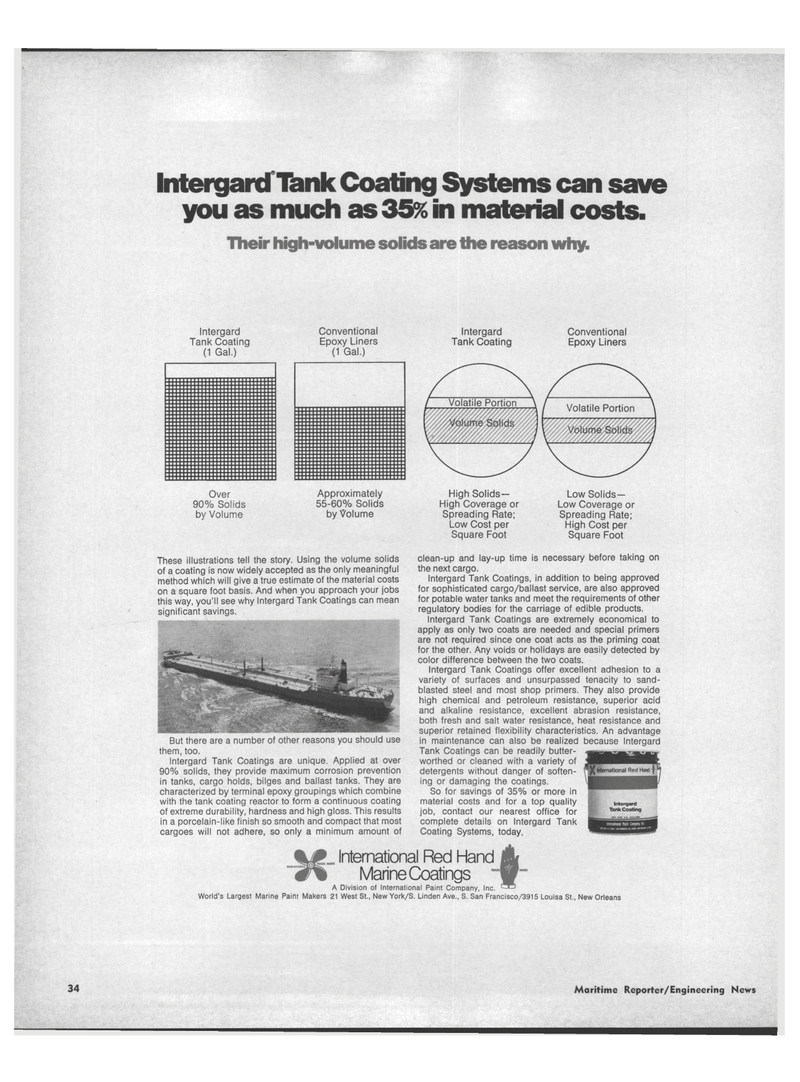

Intergard Conventional Intergard Conventional

Tank Coating Epoxy Liners Tank Coating Epoxy Liners (1 Gal.) (1 Gal.)

Over 90% Solids by Volume

Approximately 55-60% Solids by Volume

High Solids-

High Coverage or

Spreading Rate;

Low Cost per

Square Foot

Low Solids-

Low Coverage or

Spreading Rate;

High Cost per

Square Foot

These illustrations tell the story. Using the volume solids of a coating is now widely accepted as the only meaningful method which will give a true estimate of the material costs on a square foot basis. And when you approach your jobs this way, you'll see why Intergard Tank Coatings can mean significant savings.

But there are a number of other reasons you should use them, too.

Intergard Tank Coatings are unique. Applied at over 90% solids, they provide maximum corrosion prevention in tanks, cargo holds, bilges and ballast tanks. They are characterized by terminal epoxy groupings which combine with the tank coating reactor to form a continuous coating of extreme durability, hardness and high gloss. This results in a porcelain-like finish so smooth and compact that most cargoes will not adhere, so only a minimum amount of clean-up and lay-up time is necessary before taking on the next cargo.

Intergard Tank Coatings, in addition to being approved for sophisticated cargo/ballast service, are also approved for potable water tanks and meet the requirements of other regulatory bodies for the carriage of edible products.

Intergard Tank Coatings are extremely economical to apply as only two coats are needed and special primers are not required since one coat acts as the priming coat for the other. Any voids or holidays are easily detected by color difference between the two coats.

Intergard Tank Coatings offer excellent adhesion to a variety of surfaces and unsurpassed tenacity to sand- blasted steel and most shop primers. They also provide high chemical and petroleum resistance, superior acid and alkaline resistance, excellent abrasion resistance, both fresh and salt water resistance, heat resistance and superior retained flexibility characteristics. An advantage in maintenance can also be realized because Intergard

Tank Coatings can be readily butter- worthed or cleaned with a variety of detergents without danger of soften- ing or damaging the coatings.

So for savings of 35% or more in material costs and for a top quality job, contact our nearest office for complete details on Intergard Tank

Coating Systems, today.

International Red Hand

Marine Coatings

A Division of International Paint Company, Inc.

World's Largest Marine Paint Makers 21 West St., New York/S. Linden Ave., S. San Francisco/3915 Louisa St., New Orleans 34 Maritime Reporter/Engineering News

Volatile Portion

31

31

33

33