Page 4: of Maritime Reporter Magazine (August 1971)

Read this page in Pdf, Flash or Html5 edition of August 1971 Maritime Reporter Magazine

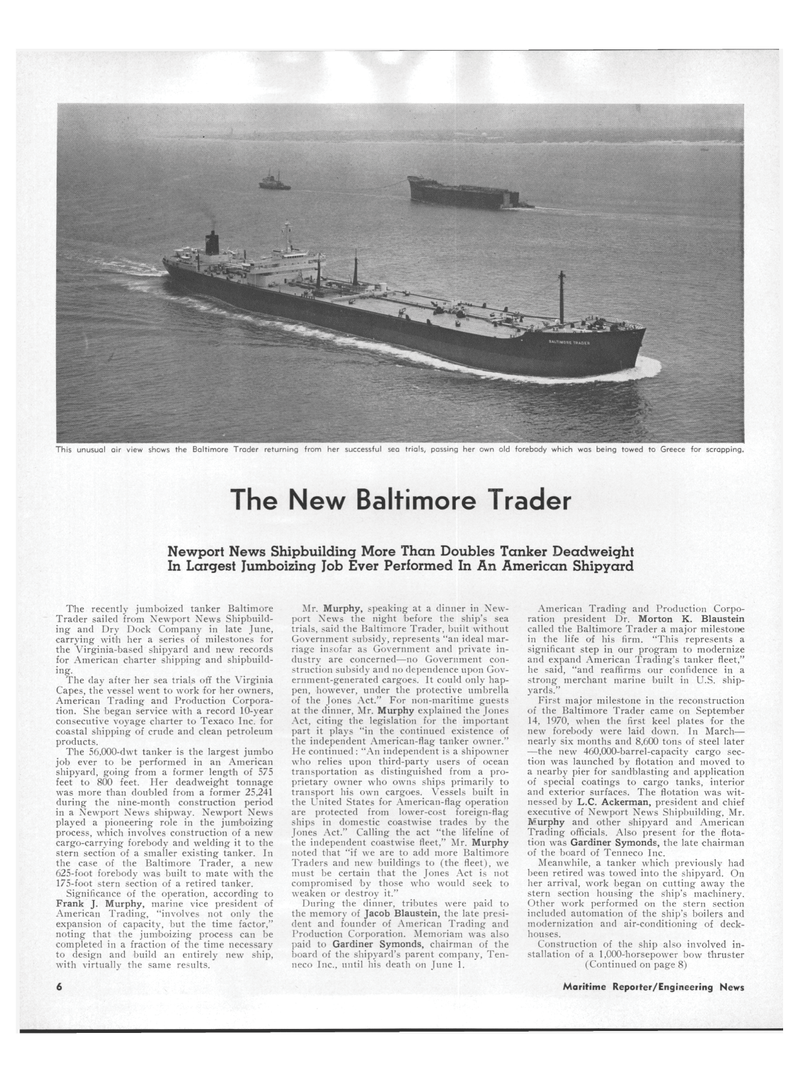

This unusual air view shows the Baltimore Trader returning from her successful sea trials, passing her own old forebody which was being towed to Greece for scrapping "he New Baltimore Trader

Newport News Shipbuilding More Than Doubles Tanker Deadweight

In Largest Jumboizing Job Ever Performed In An American Shipyard

The recently jumboized tanker Baltimore

Trader sailed from Newport News Shipbuild- ing and Dry Dock Company in late June, carrying with her a series of milestones for the Virginia-based shipyard and new records for American charter shipping and shipbuild- ing.

The day after her sea trials off the Virginia

Capes, the vessel went to work for her owners,

American Trading and Production Corpora- tion. She began service with a record 10-year consecutive voyage charter to Texaco Inc. for coastal shipping of crude and clean petroleum products.

The 56,000-dwt tanker is the largest jumbo job ever to be performed in an American shipyard, going from a former length of 575 feet to 800 feet. Her deadweight tonnage was more than doubled from a former 25,241 during the nine-month construction period in a Newport News shipway. Newport News played a pioneering role in the jumboizing process, which involves construction of a new cargo-carrying forebody and welding it to the stern section of a smaller existing tanker. In the case of the Baltimore Trader, a new 625-foot forebody was built to mate with the 175-foot stern section of a retired tanker.

Significance of the operation, according to

Frank J. Murphy, marine vice president of

American Trading, "involves not only the expansion of capacity, but the time factor," noting that the jumboizing process can be completed in a fraction of the time necessary to design and build an entirely new ship, with virtually the same results.

Mr. Murphy, speaking at a dinner in New- port News the night before the ship's sea trials, said the Baltimore Trader, built without

Government subsidy, represents "an ideal mar- riage insofar as Government and private in- dustry are concerned—no Government con- struction subsidy and no dependence upon Gov- ernment-generated cargoes. It could only hap- pen, however, under the protective umbrella of the Jones Act." For non-maritime guests at the dinner, Mr. Murphy explained the Jones

Act, citing the legislation for the important part it plays "in the continued existence of the independent American-flag tanker owner."

He continued : "An independent is a shipowner who relies upon third-party users of ocean transportation as distinguished from a pro- prietary owner who owns ships primarily to transport his own cargoes. Vessels built in the United States for American-flag operation are protected from lower-cost foreign-flag ships in domestic coastwise trades by the

Jones Act." Calling the act "the lifeline of the independent coastwise fleet," Mr. Murphy noted that "if we are to add more Baltimore

Traders and new buildings to (the fleet), we must be certain that the Jones Act is not compromised by those who would seek to weaken or destroy it."

During the dinner, tributes were paid to the memory of Jacob Blaustein, the late presi- dent and founder of American Trading and

Production Corporation. Memoriam was also paid to Gardiner Symonds, chairman of the board of the shipyard's parent company, Ten- neco Inc., until his death on June 1.

American Trading and Production Corpo- ration president Dr. Morton K. Blaustein called the Baltimore Trader a major milestone in the life of his firm. "This represents a significant step in our program to modernize and expand American Trading's tanker fleet," he said, "and reaffirms our confidence in a strong merchant marine built in U.S. ship- yards."

First major milestone in the reconstruction of the Baltimore Trader came on September 14, 1970, when the first keel plates for the new forebody were laid down. In March— nearly six months and 8,600 tons of steel later —the new 460,000-barrel-capacity cargo sec- tion was launched by flotation and moved to a nearby pier for sandblasting and application of special coatings to cargo tanks, interior and exterior surfaces. The flotation was wit- nessed by L.C. Ackerman, president and chief executive of Newport News Shipbuilding, Mr.

Murphy and other shipyard and American

Trading officials. Also present for the flota- tion was Gardiner Symonds, the late chairman of the board of Tenneco Inc.

Meanwhile, a tanker which previously had been retired was towed into the shipyard. On her arrival, work began on cutting away the stern section housing the ship's machinery.

Other work performed on the stern section included automation of the ship's boilers and modernization and air-conditioning of deck- houses.

Construction of the ship also involved in- stallation of a 1,000-horsepower bow thruster (Continued on page 8) 6 Maritime Reporter/Engineering News

3

3

5

5