Page 7: of Maritime Reporter Magazine (August 15, 1971)

Read this page in Pdf, Flash or Html5 edition of August 15, 1971 Maritime Reporter Magazine

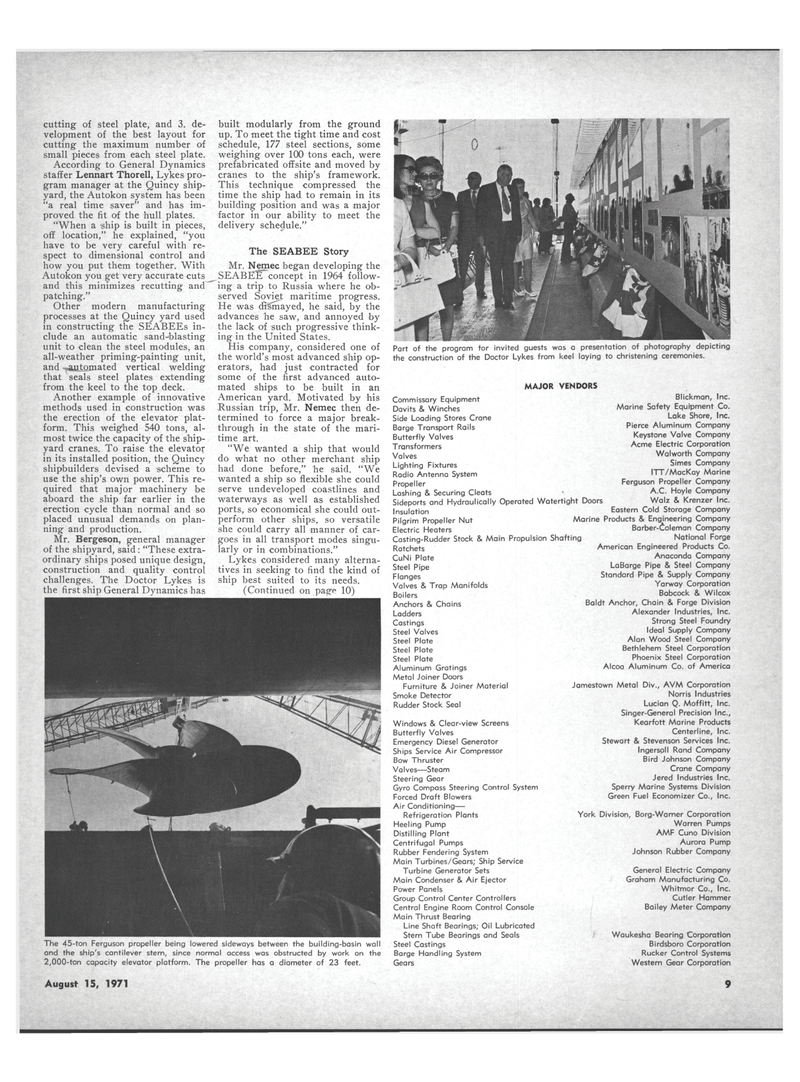

Part of the program tor invited guests was a presentation of photography depicting the construction of the Doctor Lykes from keel laying to christening ceremonies.

MAJOR VENDORS

Commissary Equipment

Davits & Winches

Side Loading Stores Crane

Barge Transport Rails

Butterfly Valves

Transformers

Valves

Lighting Fixtures

Radio Antenna System

Propeller

Lashing & Securing Cleats

Sideports and Hydraulically Operated Watertight Doors

Insulation

Pilgrim Propeller Nut

Electric Heaters

Casting-Rudder Stock & Main Propulsion Shafting

Ratchets

CuNi Plate

Steel Pipe

Flanges

Valves & Trap Manifolds

Boilers

Anchors & Chains

Ladders

Castings

Steel Valves

Steel Plate

Steel Plate

Steel Plate

Aluminum Gratings

Metal Joiner Doors

Furniture & Joiner Material

Smoke Detector

Rudder Stock Seal

Blickman, Inc.

Marine Safety Equipment Co.

Lake Shore, Inc.

Pierce Aluminum Company

Keystone Valve Company

Acme Electric Corporation

Walworth Company

Simes Company

ITT/MacKay Marine

Ferguson Propeller Company

A.C. Hoyle Company

Walz & Krenzer Inc.

Eastern Cold Storage Company

Marine Products & Engineering Company

Barber-ioleman Company

National Forge

American Engineered Products Co.

Anaconda Company

LaBarge Pipe & Steel Company

Standard Pipe & Supply Company

Yarway Corporation

Babcock & Wilcox

Baldt Anchor, Chain & Forge Division

Alexander Industries, Inc.

Strong Steel Foundry

Ideal Supply Company

Alan Wood Steel Company

Bethlehem Steel Corporation

Phoenix Steel Corporation

Alcoa Aluminum Co. of America

Windows & Clear-view Screens

Butterfly Valves

Emergency Diesel Generator

Ships Service Air Compressor

Bow Thruster

Valves—Steam

Steering Gear

Gyro Compass Steering Control System

Forced Draft Blowers

Air Conditioning—

Refrigeration Plants

Heeling Pump

Distilling Plant

Centrifugal Pumps

Rubber Fendering System

Main Turbines/Gears; Ship Service

Turbine Generator Sets

Main Condenser & Air Ejector

Power Panels

Group Control Center Controllers

Central Engine Room Control Console

Main Thrust Bearing

Line Shaft Bearings; Oil Lubricated

Stern Tube Bearings and Seals

Steel Castings

Barge Handling System

Gears

Jamestown Metal Div., AVM Corporation

Norris Industries

Lucian Q. Moffitt, Inc.

Singer-General Precision Inc.,

Kearfott Marine Products

Centerline, Inc.

Stewart & Stevenson Services Inc.

Ingersoll Rand Company

Bird Johnson Company

Crane Company

Jered Industries Inc.

Sperry Marine Systems Division

Green Fuel Economizer Co., Inc.

York Division, Borg-Warner Corporation

Warren Pumps

AMF Cuno Division

Aurora Pump

Johnson Rubber Company

General Electric Company

Graham Manufacturing Co.

Whitmor Co., Inc.

Cutler Hammer

Bailey Meter Company

Waukesha Bearing Corporation

Birdsboro Corporation

Rucker Control Systems

Western Gear Corporation cutting of steel plate, and 3. de- velopment of the best layout for cutting the maximum number of small pieces from each steel plate.

According to General Dynamics staffer Lennart Thorell, Lykes pro- gram manager at the Quincy ship- yard, the Autokon system has been "a real time saver" and has im- proved the fit of the hull plates. "When a ship is built in pieces, off location," he explained, "you have to be very careful with re- spect to dimensional control and how you put them together. With

Autokon you get very accurate cuts and this minimizes recutting and patching."

Other modern manufacturing processes at the Quincy yard used in constructing the SEABEEs in- clude an automatic sand-blasting unit to clean the steel modules, an all-weather priming-painting unit, and -^automated vertical welding that seals steel plates extending from the keel to the top deck.

Another example of innovative methods used in construction was the erection of the elevator plat- form. This weighed 540 tons, al- most twice the capacity of the ship- yard cranes. To raise the elevator in its installed position, the Quincy shipbuilders devised a scheme to use the ship's own power. This re- quired that major machinery be aboard the ship far earlier in the erection cycle than normal and so placed unusual demands on plan- ning and production.

Mr. Bergeson, general manager of the shipyard, said : "These extra- ordinary ships posed unique design, construction and quality control challenges. The Doctor Lykes is the first ship General Dynamics has built modularly from the ground up. To meet the tight time and cost schedule, 177 steel sections, some weighing over 100 tons each, were prefabricated offsite and moved by cranes to the ship's framework.

This technique compressed the time the ship had to remain in its building position and was a major factor in our ability to meet the delivery schedule."

The SEABEE Story

Mr. Nemec began developing the

SEABEE concept in 1964 follow- ing a trip to Russia where he ob- served Soviet maritime progress.

He was drlmayed, he said, by the advances he saw, and annoyed by the lack of such progressive think- ing in the United States.

His company, considered one of the world's most advanced ship op- erators, had just contracted for some of the first advanced auto- mated ships to be built in an

American yard. Motivated by his

Russian trip, Mr. Nemec then de- termined to force a major break- through in the state of the mari- time art. "We wanted a ship that would do what no other merchant ship had done before," he said. "We wanted a ship so flexible she could serve undeveloped coastlines and waterways as well as established ports, so economical she could out- perform other ships, so versatile she could carry all manner of car- goes in all transport modes singu- larly or in combinations."

Lykes considered many alterna- tives in seeking to find the kind of ship best suited to its needs. (Continued on .page 10)

The 45-ton Ferguson propeller being lowered sideways between the building-basin wall and the ship's cantilever stern, since normal access was obstructed by work on the 2,000-ton capacity elevator platform. The propeller has a diameter of 23 feet.

August 15, 1971 9

6

6

8

8