Page 3rd Cover: of Maritime Reporter Magazine (September 1971)

Read this page in Pdf, Flash or Html5 edition of September 1971 Maritime Reporter Magazine

Eight Barges For Union Carbide

With Stainless Steel Tanks

Delivered By St. Louis Ship

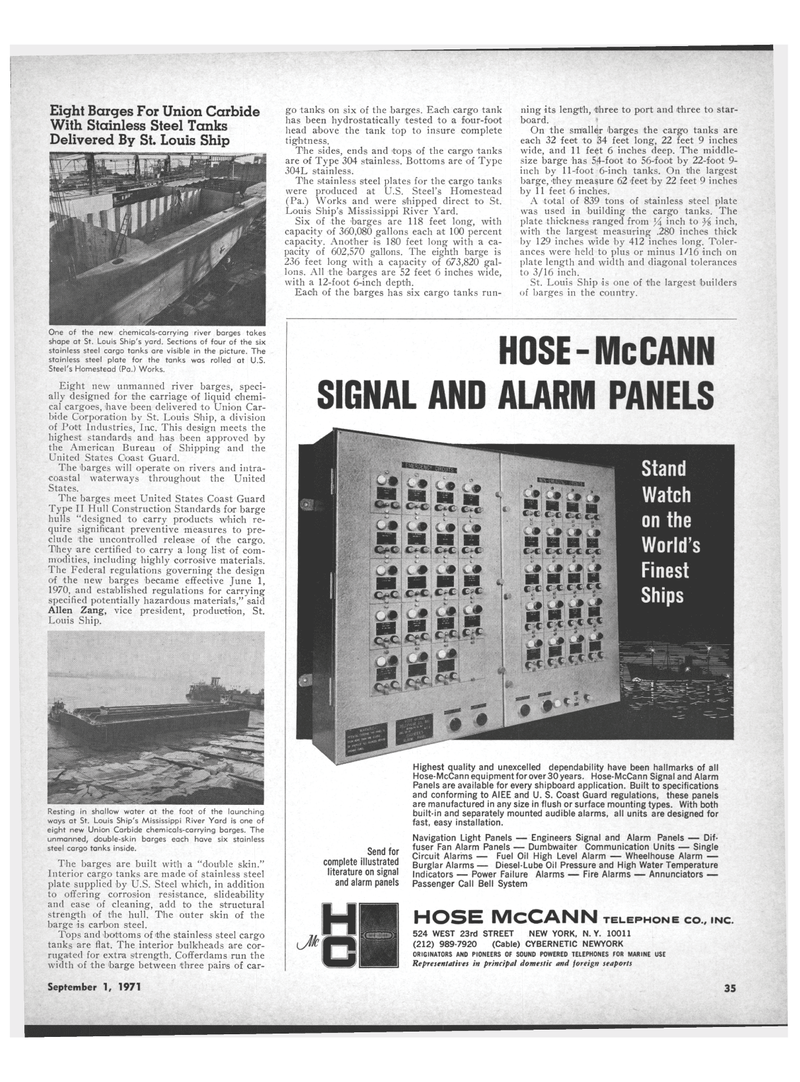

One of the new chemicals-carrying river barges takes shape at St. Louis Ship's yard. Sections of four of the six stainless steel cargo tanks are visible in the picture. The stainless steel plate for the tanks was rolled at U.S.

Steel's Homestead (Pa.) Works.

Eight new unmanned river barges, speci- ally designed for the carriage of liquid chemi- cal cargoes, have been delivered to Union Car- bide Corporation by St. Louis Ship, a division of Pott Industries, Inc. This design meets the highest standards and has been approved by the American Bureau of Shipping and the

United States Coast Guard.

The barges will operate on rivers and intra- coastal waterways throughout the United

States.

The barges meet United States Coast Guard

Type II Hull Construction Standards for barge hulls "designed to carry products which re- quire significant preventive measures to pre- clude the uncontrolled release of the cargo.

They are certified to carry a long list of com- modities, including highly corrosive materials.

The Federal regulations governing the design of the new barges became effective June 1, 1970, and established regulations for carrying specified potentially hazardous materials," said

Allen Zang, vice president, production, St.

Louis Ship.

Resting in shallow water at the foot of the launching ways at St. Louis Ship's Mississippi River Yard is one of eight new Union Carbide chemicals-carrying barges. The unmanned, double-skin barges each have six stainless steel cargo tanks inside.

The barges are built with a "double skin."

Interior cargo tanks are made of stainless steel plate supplied by U.S. Steel whic'h, in addition to offering corrosion resistance, slideability and ease of cleaning, add to the structural strength of the hull. The outer skin of the barge is carbon steel.

Tops and bottoms of tihe stainless steel cargo tanks are flat. The interior bulkheads are cor- rugated for extra strength. Cofferdams run the width of the barge between three pairs of car- go tanks on six of the barges. Eadh cargo tank has been hydrostatically tested to a four-foot head above the tank top to insure complete tightness.

The sides, ends and tops of the cargo tanks are of Type 304 stainless. Bottoms are of Type 304L stainless.

The stainless steel plates for the cargo tanks were produced at U.S. Steel's Homestead (Pa.) Works and were shipped direct to St.

Louis Ship's Mississippi River Yard.

Six of the barges are 118 feet long, with capacity of 360,080 gallons each at 100 percent capacity. Another is 180 feet long with a ca- pacity of 602,570 gallons. The eighth barge is 236 feet long with a capacity of 673,820 gal- lons. All the barges are 52 feet 6 inches wide, with a 12-foot 6-inch depth.

Each of the barges has six cargo tanks run- ning its length, three to port and three to star- board.

On the smaller 'barges the cargo tanks are each 32 feet to 34 feet long, 22 feet 9 inches wide, and 11 feet 6 inches deep. The middle- size barge has 54-foot to 56-foot by 22-foot 9- inch by 11-foot 6-inch tanks. On the largest barge, 'they measure 62 'feet by 22 feet 9 inches by 11 feet 6 inches.

A total of 839 tons of stainless steel plate was used in building the cargo tanks. The plate thickness ranged from % inch to % inch, with the largest measuring .280 inches thick by 129 inches wide by 412 inches long. Toler- ances were held to plus or minus 1/16 inch on plate length and width and diagonal tolerances to 3/16 inch.

St. Louis Ship is one of the largest builders of barges in the country.

HOSE-McCANN

SIGNAL AND ALARM PANELS -t -

C# oc

C # v* Kfl m cm c # ir , -S - -

Cft

C'C £# if i9 as1 BN«b c^cccc^n- • i m; C^C C-C tc » L_ »...: •» .. : J c c c c c^c c,c 1 if g * 4 ^ iM! M

Stand

Watch on the

World's

Finest

Ships

Send for complete illustrated literature on signal and alarm panels

Highest quality and unexcelled dependability have been hallmarks of all

Hose-McCannequipmentforover30years. Hose-McCann Signal and Alarm

Panels are available for every shipboard application. Built to specifications and conforming to AIEE and U. S. Coast Guard regulations, these panels are manufactured in any size in flush or surface mounting types. With both built-in and separately mounted audible alarms, all units are designed for fast, easy installation.

Navigation Light Panels — Engineers Signal and Alarm Panels — Dif- fuser Fan Alarm Panels — Dumbwaiter Communication Units — Single

Circuit Alarms — Fuel Oil High Level Alarm — Wheelhouse Alarm —

Burglar Alarms — Diesel-Lube Oil Pressure and High Water Temperature

Indicators — Power Failure Alarms — Fire Alarms — Annunciators —

Passenger Call Bell System

HOSE McCANN TELEPHONE CO, 524 WEST 23rd STREET NEW YORK, N.Y. 10011 (212) 989-7920 (Cable) CYBERNETIC NEWYORK

ORIGINATORS AND PIONEERS OF SOUND POWERED TELEPHONES FOR MARINE USE

Representatives in principal domestic and foreign seaports

INC.

September 1, 1971 35

32

32

4th Cover

4th Cover