Page 3: of Maritime Reporter Magazine (October 1971)

Read this page in Pdf, Flash or Html5 edition of October 1971 Maritime Reporter Magazine

MM

Propeller Speed

Propeller

Time - . .vK«..v.' Stopped

Stop stalling...with

Fawick marine propeller shaft brakes

F:T< Power Transmission Systems

Full Ahead

Peak HP—Clutch Only

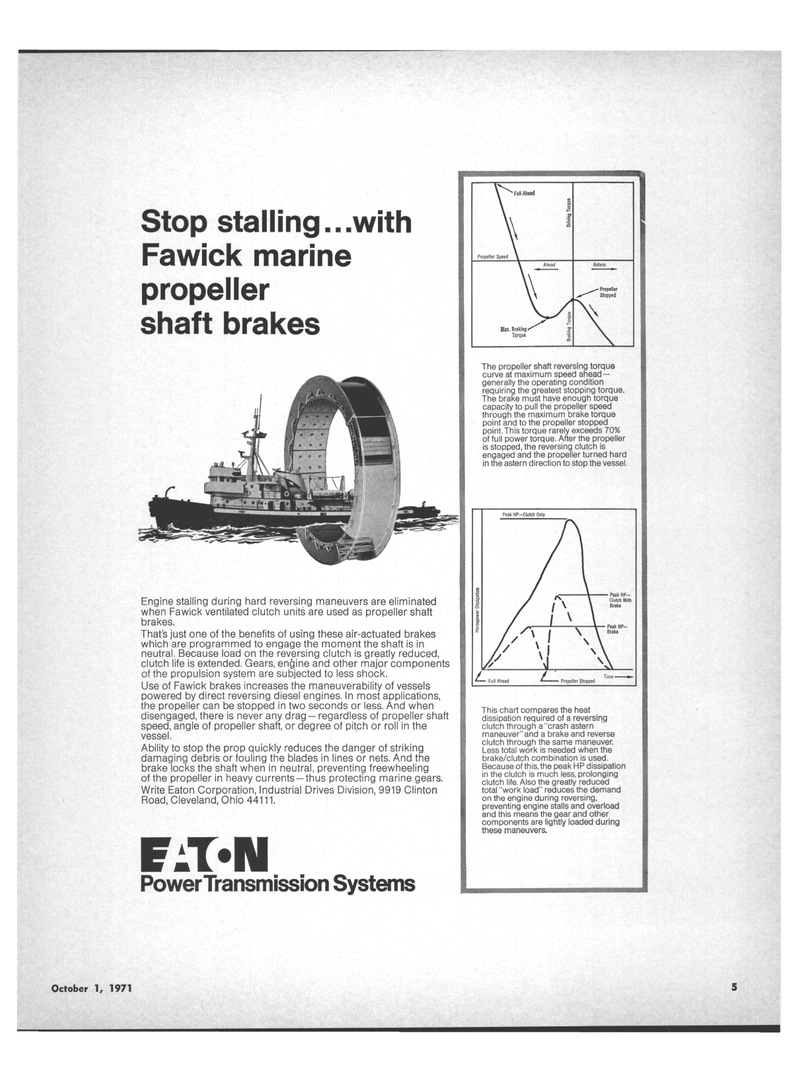

The propeller shaft reversing torque curve at maximum speed ahead — generally the operating condition requiring the greatest stopping torque.

The brake must have enough torque capacity to pull the propeller speed through the maximum brake torque point and to the propeller stopped point. This torque rarely exceeds 70% of full power torque. After the propeller is stopped, the reversing clutch is engaged and the propeller turned hard in the astern direction to stop the vessel.

This chart compares the heat dissipation required of a reversing clutch through a "crash astern maneuver" and a brake and reverse clutch through the same maneuver.

Less total work is needed when the brake/clutch combination is used.

Because of this, the peak HP dissipation in the clutch is much less, prolonging clutch life. Also the greatly reduced total "work load" reduces the demand on the engine during reversing, preventing engine stalls and overload and this means the gear and other components are lightly loaded during these maneuvers.

Peak HP-

Clutch With

Brake Engine stalling during hard reversing maneuvers are eliminated when Fawick ventilated clutch units are used as propeller shaft brakes.

That's just one of the benefits of using these air-actuated brakes which are programmed to engage the moment the shaft is in neutral. Because load on the reversing clutch is greatly reduced, clutch life is extended. Gears, engine and other major components of the propulsion system are subjected to less shock.

Use of Fawick brakes increases the maneuverability of vessels powered by direct reversing diesel engines. In most applications, the propeller can be stopped in two seconds or less. And when disengaged, there is never any drag — regardless of propeller shaft speed, angle of propeller shaft, or degree of pitch or roll in the vessel.

Ability to stop the prop quickly reduces the danger of striking damaging debris or fouling the blades in lines or nets. And the brake locks the shaft when in neutral, preventing freewheeling of the propeller in heavy currents —thus protecting marine gears.

Write Eaton Corporation, Industrial Drives Division, 9919 Clinton

Road, Cleveland, Ohio 44111.

October 1, 1971 5

2

2

4

4