Page 46: of Maritime Reporter Magazine (December 1971)

Read this page in Pdf, Flash or Html5 edition of December 1971 Maritime Reporter Magazine

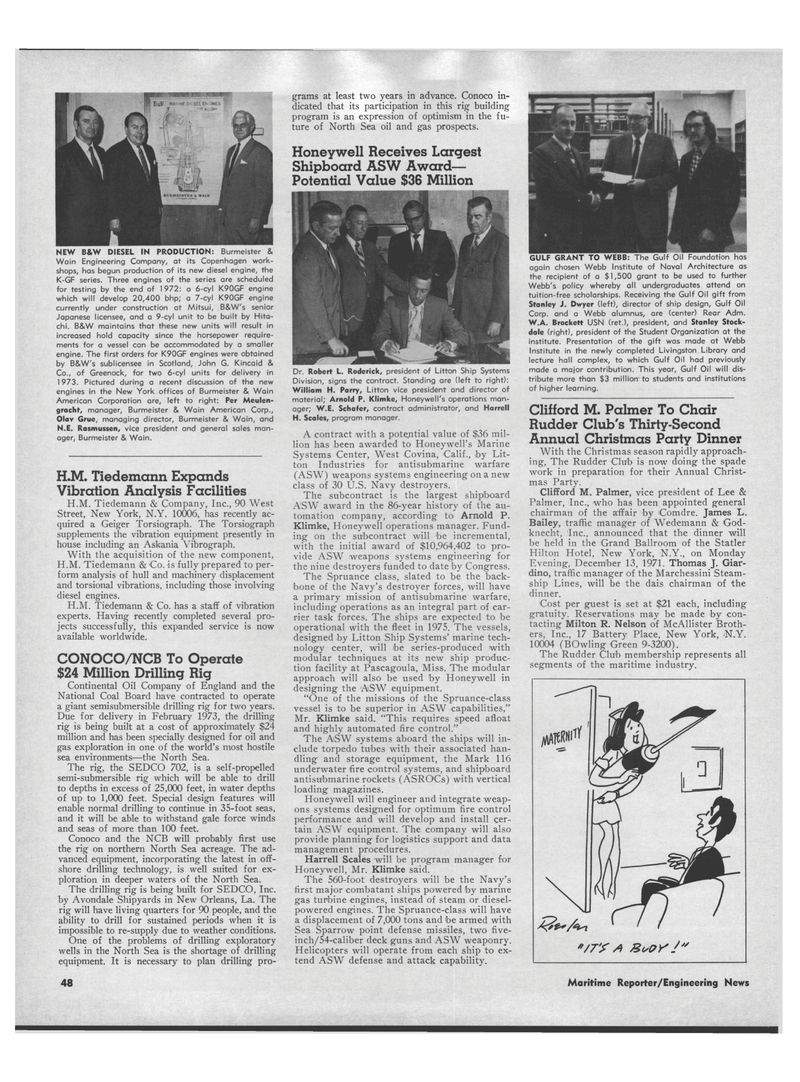

NEW B&W DIESEL IN PRODUCTION: Burmeister &

Wain Engineering Company, at its Copenhagen work- shops, has begun production of its new diesel engine, the

K-GF series. Three engines of the series are scheduled for testing by the end of 1972: a 6-cyl K90GF engine which will develop 20,400 bhp; a 7-cyl K90GF engine currently under construction at Mitsui, B&W's senior

Japanese licensee, and a 9-cyl unit to be built by Hita- chi. B&W maintains that these new units will result in increased hold capacity since the horsepower require- ments for a vessel can be accommodated by a smaller engine. The first orders for K90GF engines were obtained by B&W's sublicensee in Scotland, John G. Kincaid &

Co., of Greenock, for two 6-cyl units for delivery in 1973. Pictured during a recent discussion of the new engines in the New York offices of Burmeister & Wain

American Corporation are, left to right: Per Meulen- gracht, manager, Burmeister & Wain American Corp.,

Olav Grue, managing director, Burmeister & Wain, and

N.E. Rasmussen, vice president and general sales man- ager, Burmeister & Wain.

H.M. Tiedemann Expands

Vibration Analysis Facilities

H.M. Tiedemann & Company, Inc., 90 West

Street, New York, N.Y. 10006, has recently ac- quired a Geiger Torsiograph. The Torsiograph supplements the vibration equipment presently in house including an Askania Vibrograph.

With the acquisition of the new component,

H.M. Tiedemann & Co. is fully prepared to per- form analysis of hull and machinery displacement and torsional vibrations, including those involving diesel engines.

H.M. Tiedemann & Co. has a staff of vibration experts. Having recently completed several pro- jects successfully, this expanded service is now available worldwide.

CONOCO/NCB To Operate $24 Million Drilling Rig

Continental Oil Company of England and the

National Coal Board have contracted to operate a giant semisubmersible drilling rig for two years.

Due for delivery in February 1973, the drilling rig is being built at a cost of approximately $24 million and has been specially designed for oil and gas exploration in one of the world's most hostile sea environments—the North Sea.

The rig, the SEDCO 702, is a self-propelled semi-submersible rig which will be able to drill to depths in excess of 25,000 feet, in water depths of up to 1,000 feet. Special design features will enable normal drilling to continue in 35-foot seas, and it will be able to withstand gale force winds and seas of more than 100 feet.

Conoco and the NCB will probably first use the rig on northern North Sea acreage. The ad- vanced equipment, incorporating the latest in off- shore drilling technology, is well suited for ex- ploration in deeper waters of the North Sea.

The drilling rig is being built for SEDCO, Inc. by Avondale Shipyards in New Orleans, La. The rig will have living quarters for 90 people, and the ability to drill for sustained periods when it is impossible to re-supply due to weather conditions.

One of the problems of drilling exploratory wells in the North Sea is the shortage of drilling equipment. It is necessary to plan drilling pro- grams at least two years in advance. Conoco in- dicated that its participation in this rig building program is an expression of optimism in the fu- ture of North Sea oil and gas prospects.

Honeywell Receives Largest

Shipboard ASW Award-

Potential Value $36 Million

Dr. Robert L. Roderick, president of Litton Ship Systems

Division, signs the contract. Standing are (left to right):

William H. Parry, Litton vice president and director of material; Arnold P. Klimke, Honeywell's operations man- ager; W.E. Schafer, contract administrator, and Harrell

H. Scales, program manager.

A contract with a potential value of $36 mil- lion has been awarded to Honeywell's Marine

Systems Center, West Covina, Calif., by Lit- ton Industries for antisubmarine warfare (ASW) weapons systems engineering on a new class of 30 U.S. Navy destroyers.

The subcontract is the largest shipboard

ASW award in the 86-year history of the au- tomation company, according to Arnold P.

Klimke, Honeywell operations manager. Fund- ing on the subcontract will be incremental, with the initial award of $10,964,402 to pro- vide ASW weapons systems engineering for the nine destroyers funded to date by Congress.

The Spruance class, slated to be the back- bone of the Navy's destroyer forces, will have a primary mission of antisubmarine warfare, including operations as an integral part of car- rier task forces. The ships are expected to be operational with the fleet in 1975. The vessels, designed by Litton Ship Systems' marine tech- nology center, will be series-produced with modular techniques at its new ship produc- tion facility at Pascagoula, Miss. The modular approach will also be used by Honeywell in designing the ASW equipment. "One of the missions of the Spruance-class vessel is to be superior in ASW capabilities,"

Mr. Klimke said. "This requires speed afloat and highly automated fire control."

The ASW systems aboard the ships will in- clude torpedo tubes with their associated han- dling and storage equipment, the Mark 116 underwater fire control systems, and shipboard antisubmarine rockets (ASRO'Cs) with vertical loading magazines.

Honeywell will engineer and integrate weap- ons systems designed for optimum fire control performance and will develop and install cer- tain ASW equipment. The company will also provide planning for logistics support and data management procedures.

Harrell Scales will be program manager for

Honeywell, Mr. Klimke said.

The 560-foot destroyers will be the Navy's first major combatant ships powered by marine gas turbine engines, instead of steam or diesel- powered engines. The Spruance-class will have a displacement of 7,000 tons and be armed with

Sea Sparrow point defense missiles, two five- inch/54-caliber deck guns and ASW weaponry.

Helicopters will operate from each ship to ex- tend ASW defense and attack capability.

GULF GRANT TO WEBB: The Gulf Oil Foundation has again chosen Webb Institute of Naval Architecture as the recipient of a $1,500 grant to be used to further

Webb's policy whereby all undergraduates attend on tuition-free scholarships. Receiving the Gulf Oil gift from

Stanley J. Dwyer (left), director of ship design, Gulf Oil

Corp. and a Webb alumnus, are (center) Rear Adm.

W.A. Brockett USN (ret.), president, and Stanley Stock- dale (right), president of the Student Organization at the institute. Presentation of the gift was made at Webb

Institute in the newly completed Livingston Library and lecture hall complex, to which Gulf Oil had previously made a major contribution. This year, Gulf Oil will dis- tribute more than $3 million to students and institutions of higher learning.

Clifford M. Palmer To Chair

Rudder Club's Thirty-Second

Annual Christmas Party Dinner

With the Christmas season rapidly approach- ing, The Rudder Club is now doing the spade work in preparation for their Annual Christ- mas Party.

Clifford M. Palmer, vice president of Lee &

Palmer, Inc., who has been appointed general chairman of the affair by Comdre. James L.

Bailey, traffic manager of Wedemann & God- knecht, Inc., announced that the dinner will be held in the Grand Ballroom of the Statler

Hilton Hotel, New York, N.Y., on Monday

Evening, December 13, 1971. Thomas J. Giar- dino, traffic manager of the Marcbessini Steam- ship Lines, will be the dais chairman of the dinner.

Cost per guest is set at $21 each, including gratuity. Reservations may be made by con- tacting Milton R. Nelson of McAllister Broth- ers, Inc., 17 Battery Place, New York, -N.Y. 10004 (BOwling Green 9-3200).

The Rudder Club membership represents all segments of the maritime industry. 48 Maritime Reporter/Engineering News

45

45

47

47