Page 7: of Maritime Reporter Magazine (March 1973)

Read this page in Pdf, Flash or Html5 edition of March 1973 Maritime Reporter Magazine

$7.5-Million Contract

Awarded To NASSCO

For Navy Ship Design

According to Navy Secretary

John Warner, National Steel and

Shipbuilding 'Company has signed on January 26, 1973, a $7.5-million contract with the U.S. Navy for the design support of a new sea control ship.

National Steel and Shipbuilding

Company will assist the Navy in the design of the new ship. NAS-

SCO will also advise on major tech- nical discussions and will introduce producibility considerations and in- novations features early in the de- sign process.

When funded, NASSCO will ac- complish detailed design of the ship and will work with the Navy at of- fices in San Diego, Calif., Hyatts- ville, M'd., and New York, N.Y.

Subject to appropriations, a year or more from now, NASSCO will be given the opportunity to negoti- ate with the Navy on construction of the lead ship.

The preliminary concept indicates that the sea control ship will have an overall length of about 610 feet, a beam of about 80 feet, with dis- placement of ajbout 14,000 tons.

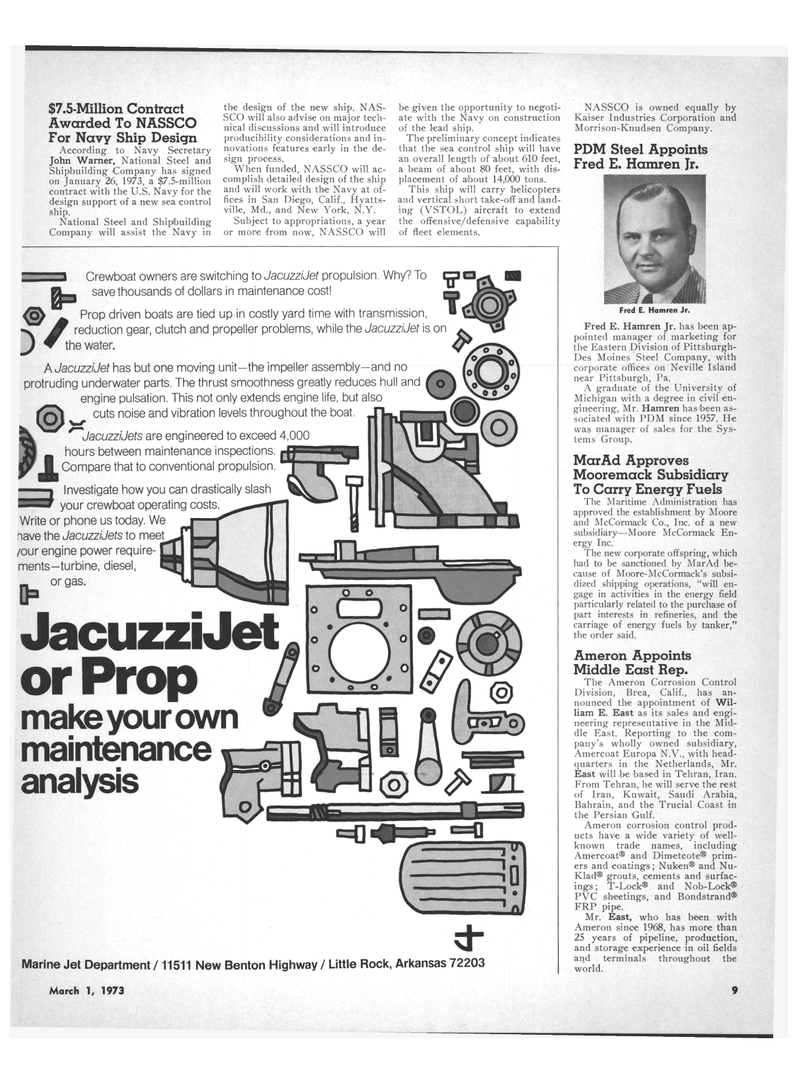

This ship will carry helicopters and vertical short take-off and land- ing (VSTOL) aircraft to extend the offensive/defensive capability of fleet elements. • Crewboat owners are switching to JacuzziJet propulsion. Why? To cp I

Q save thousands of dollars in maintenance cost! q ^ Prop driven boats are tied up in costly yard time with transmission, • ^ M reduction gear, clutch and propeller problems, while the JacuzziJet is on

J W the water.

A JacuzziJet has but one moving unit—the impeller assembly-and no protruding underwater parts. The thrust smoothness greatly reduces hull and engine pulsation. This not only extends engine life, but also cuts noise and vibration levels throughout the boat. mjr ~~JacuzziJets are engineered to exceed 4,000 . _ hours between maintenance inspections

I Compare that to conventional propulsion

Investigate how you can drastically slash your crewboat operating costs

Write or phone us today. We have the JacuzziJets to meet /our engine power require- ments—turbine, diesel, « or gas. D3

JacuzziJet. or Prop ff make your own maintenance analysis d-

Marine Jet Department /11511 New Benton Highway / Little Rock, Arkansas 72203

March 1, 1973

NAS'SCO is owned equally by

Kaiser Industries Corporation and

Morrison-Knudsen Company.

PDM Steel Appoints

Fred E. Hamren Jr.

Fred E. Hamren Jr.

Fred E. Hamren Jr. has been ap- pointed manager of marketing for the Eastern Division of Pittsburgh-

Des Moines Steel Company, with corporate offices on Neville Island near Pittsburgh, Pa.

A graduate of the University of

Michigan with a degree in civil en- gineering, Mr. Hamren has been as- sociated with PDM since 1957. He was manager of sales for the Sys- tems Group.

MarAd Approves

Mooremack Subsidiary

To Carry Energy Fuels

The Maritime Administration has approved the establishment by Moore and McCormack Co., Inc. of a new subsidiary—Moore McCormack En- ergy Inc.

The new corporate offspring, which had to be sanctioned by MarAd be- cause of Moore-McCormack's subsi- dized shipping operations, "will en- gage in activities in the energy field particularly related to the purchase of part interests in refineries, and the carriage of energy fuels by tanker," the order said.

Ameron Appoints

Middle East Rep.

The Ameron Corrosion Control

Division, Brea, Calif., has an- nounced the appointment of Wil- liam E. East as its sales and engi- neering representative in the Mid- dle East. Reporting to the com- pany's wholly owned subsidiary,

Amercoat Europa N.V., with head- quarters in the Netherlands, Mr.

East will be based in Tehran, Iran.

From Tehran, he will serve the rest of Iran, Kuwait, Saudi Arabia,

Bahrain, and the Trucial Coast in the Persian Gulf.

Ameron corrosion control prod- ucts have a wide variety of well- known trade names, including

Amercoat® and Dimetcote® prim- ers and coatings; Nuken® and Nu-

Klad® grouts, cements and surfac- ings; T-Lock® and Nob-Lock®

PVC sheetings, and Bondstrand®

FRP pipe.

Mr. East, who has been with

Ameron since 1968, has more than 25 years of pipeline, production, and storage experience in oil fields and terminals throughout the world. 9

6

6

8

8