Page 27: of Maritime Reporter Magazine (March 15, 1973)

Read this page in Pdf, Flash or Html5 edition of March 15, 1973 Maritime Reporter Magazine

Herrman To Direct

Alcoa Marketing

In LNG Industry

George E. Herrman

To direct and coordinate its role as a major supplier to the inter- nationally expanding liquefied natu- ral gas industry, Aluminum Com- pany of America, Pittsburgh, Pa. 15219, has named George E. Herr- man as corporate manager-LNG.

Mr. Herrman will be responsible for formulating and implementing

Alcoa's worldwide marketing strategies to all facets of the lique- fied natural gas industry.

A graduate of the University of

Michigan, Mr. Herrman joined Al- coa in Detroit in 1948 as a sales engineer. In 1957, he moved to

Pittsburgh to become commercial automotive sales manager. He was named transportation industry sales manager in 1960 and has been general manager - industry sales since 1968.

Global Terminal Names

JJB. Barbera Exec. VP

Richard T. Norton, president of

Global Terminal & Container Serv- ices, Inc., Port Jersey, N.J., has announced the promotion of Jo- seph N. Barbera to the newly cre- ated position of executive vice president.

Mr. Barbera joined Global Ter- minal & Container Services as a vice president, and has been with the firm from the coneeptional to the present operational phase. He was formerly associated with Sea-

Land Services, 'Inc., and the U.S.

Treasury Department, Internal

Revenue Service. A former resi- dent of Jersey City, 'N.J., Mr. Bar- bera obtained his B.S. degree at

St. Peter's College.

Seatrain Shipbuilding

Names New President —Two Vice Presidents

Seatrain Lines, Inc. has an- nounced a realignment of the top management of its shipbuilding operations, naming a new president and two vice presidents—a special- ist in steel fabrication and in pro- duction scheduling.

Elected president of Seatrain

Shipbuilding Corp., a wholly own- ed subsidiary of the parent, was

Thomas P. Howes formerly assist- ant group general manager at In- ternational Telephone & Telegraph

Corp. and responsible for 10 of its companies. He !has been associated with North American IT&T since 1964, first as director of operations staffs in Canada, then as general manager of IT&T's Communica- tions Systems Companies. He is a graduate of Harvard College, and received his master's degree in business administration at Colum- bia University.

Mr. Howes succeeds Warren B.

Pack, who has been reassigned to a corporate supervisory position coordinating the operations of all divisions of Seatrain Lines. Mr.

Pack has been in charge of the shipyard since the company began operating there in 1969, and presi- dent of the shipyard subsidiary since 1970. He was responsible for redeveloping the former Brooklyn

Navy Yard and initiating construc- tion of the two 225,000-dwt tankers now being completed there—"the largest tankers ever built in the

United States.

Named vice presidents were

Raymond J. Cicconi, general su- perintendent of U.S. Steel Corpo- ration's American Bridge Division plant at Orange, Texas, and Stuart

Rock, vice president-manufactur- ing at Tech-Serv, Inc. and previ- ously director of operations at Re- public Electronic Industries Corp.

Mr. Cicconi is a graduate of Elmira

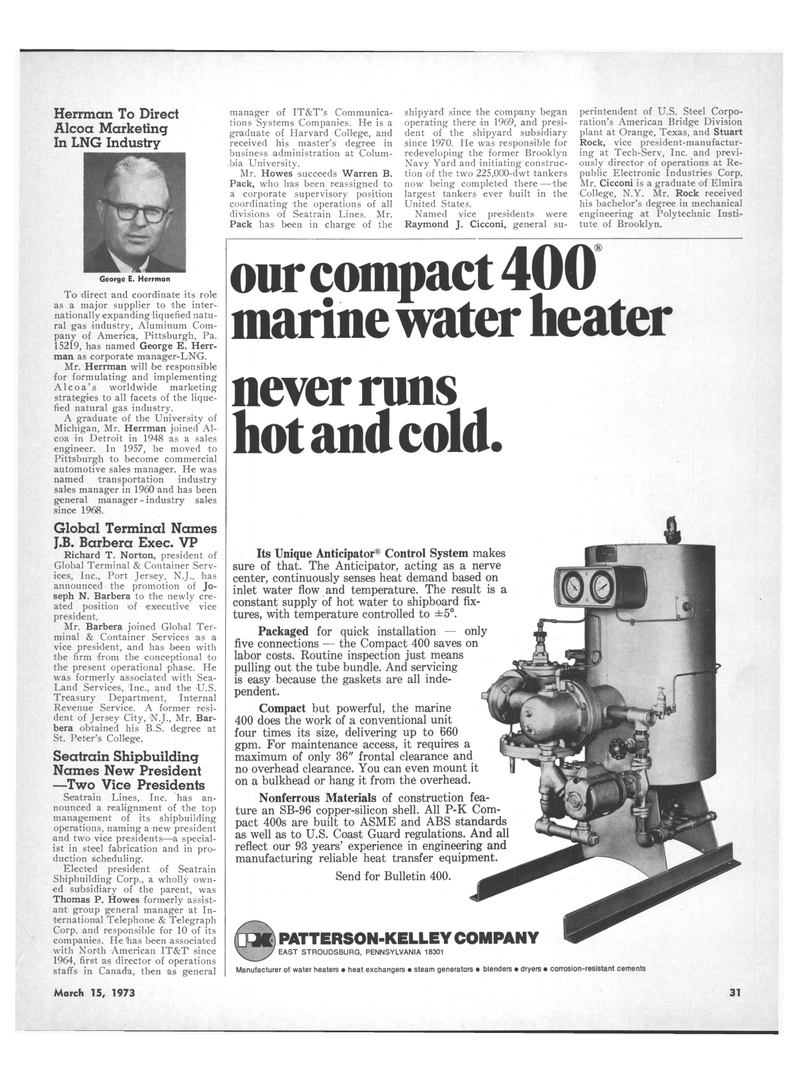

College, N.Y. Mr. Rock received his bachelor's degree in mechanical engineering at Polytechnic Insti- tute of Brooklyn. our compact 400 marine water heater never runs hot and cold.

Manufacturer of water heaters • heat exchangers • steam generators • blenders • dryers • corrosion-resistant cements (Q*) PATTERSON-KELLEY COMPANY

EAST STROUDSBURG, PENNSYLVANIA 18301

Its Unique Anticipator® Control System makes sure of that. The Anticipator, acting as a nerve center, continuously senses heat demand based on inlet water flow and temperature. The result is a constant supply of hot water to shipboard fix- tures, with temperature controlled to ±5°.

Packaged for quick installation — only five connections — the Compact 400 saves on labor costs. Routine inspection just means pulling out the tube bundle. And servicing is easy because the gaskets are all inde- pendent.

Compact but powerful, the marine 400 does the work of a conventional unit four times its size, delivering up to 660 gpm. For maintenance access, it requires a maximum of only 36" frontal clearance and no overhead clearance. You can even mount it on a bulkhead or hang it from the overhead.

Nonferrous Materials of construction fea- ture an SB-96 copper-silicon shell. All P-K Com- pact 400s are built to ASME and ABS standards as well as to U.S. Coast Guard regulations. And all reflect our 93 years' experience in engineering and manufacturing reliable heat transfer equipment.

Send for Bulletin 400.

March 15, 1973 31

26

26

28

28