Page 11: of Maritime Reporter Magazine (April 1973)

Read this page in Pdf, Flash or Html5 edition of April 1973 Maritime Reporter Magazine

and 250-A are 12.5 and 12.9 respectively, whereas this ratio on 500-A is 10.0. In general, the thickness of the deck and bottom shell plating decrease as the L/D ratio decreases.

Therefore, as L/D is reduced from 12.5 or 12.9 it is possible 'to replace HTS steel with ordi- nary strength steel. In the case of the 500-A design, the L/D ratio was already very low, find it was not possible to replace high- strength steel by ordinary strength steel to any great extent.

The outfit weights for all designs fall in a narrow range between .08 and .11 of the total light ship weights with the lower values oc- curring on the deeper ships which experience appreciable increases in steel weight.

The longitudinal strength studies performed for 45-percent, 60-percent, and full-load dis- placements showed that all designs in each series required the same section modulus with- in a given series. As a result, all midship sections were designed to approximately stand- ard ABS section modulus.

Using data from Japanese sources as rep- resentative and Government and industry ex- perience in the field, the prices for each of the 12 designs in this study were estimated.

These figures are shown in Table 1, and rep- resent shipyard selling prices.

Table 1—SUMMARY OF SHIPBUILDING PRICES (Prices given in million dollars at Yen conversion of 308 to the dollar.)

Percent

Increase

Ship 1974 Over

Category Price Base Ship 250-A 37.3 250 IMCO 37.7 0 250-B1 40.1 6.2 250-B2 41.0 8.7 250-C 44.3 17.5 250-D 41.8 10.8 250-E1 39^3 4.2 250-E2 41.4 9.8

Estimates of the cost differences in material and labor requirements and other direct and indirect costs established the prices for ships which departed from conventional designs.

Labor requirements reflected adjustments for added complications in construction due to double bottoms and sides.

The estimates are based on the premises that shipyard experience and facilities are ade- quate to build any of these designs; that pric- ing- of all designs are suitably related to make a contract for any one of them equally at- tractive to the shipyard; and that owners will no longer be restricted to only the conven- tional design but may choose one or .more of the unconventional designs for quantity or- ders in the future.

As noted earlier, the study devoted primary attention to the major areas of cost differences.

Other items such as ballast pumps, anchors and chain, hatches, manholes and gratings, and vertical inclined ladders were compared and priced to examine their significance.

Conclusions

The results show that additional segregated ballast capacity has helped significantly in im- proving oil outflow from normal operation. It is important to note, however, that the level of effectiveness in reducing oil outflows from operational as well as accidental pollution is strongly dependent on a number of the fol- lowing :

L The operational pollution effectiveness of the base ship design, i.e. the tank washing procedure, settling, and decanting; 2. The values of effectiveness assigned to double-bottom designs in mitigating opera- tional pollution; and 3. The values of effectiveness assigned to the various designs in limiting accidental pol- lution. In this regard, it is important to note that none of the designs produce a high degree of effectiveness against both strandings and collisions.

In general, it can be said that any of the design variations considered are an effective means to mitigate oil pollution resulting from normal tanker operations for normal ballast levels between 45 and 60 percent of full-load displacement. The cost effectiveness data for operational pollution suggest that the stag- gered wing version, 250-E1, is the best, fol- lowed by the double bottoms, 250-B1 and 250-

B-2, and the double-bottom, double-side ver- sion, 250-C.

When overall cost effectiveness (including accidents) is considered, then the two double- bottom versions, 250-B1 and 250-B2, appear best, followed by the staggered-wing version, 250-El, and then the double-skin version, 250-C. These rankings are somewhat depend- ent upon the relative magnitude of accidental pollution from strandings and collisions.

When the study was originally conducted, the assumption was made that the ratio of outflows from strandings to collisions was 2 to 1. Subsequent data and analysis have shown that this ratio appears now to be on the order of 4 to 1. The same study has shown <3 -£3 £3 that annual oil outflow due to groundings, collisions and rammings is on the' order of 81,000 tons per year, which compares well with the earlier assumption of 100,000 cubic meters. If these data were used, the double- bottom versions would be more effective, the double-skin only slightly less effective, while the double-side and staggered single-skin ver- sions would have appeared significantly less effective.

Another important factor in making any de- cisions with respect to the overall effectiveness is the role of accident-prevention techniques.

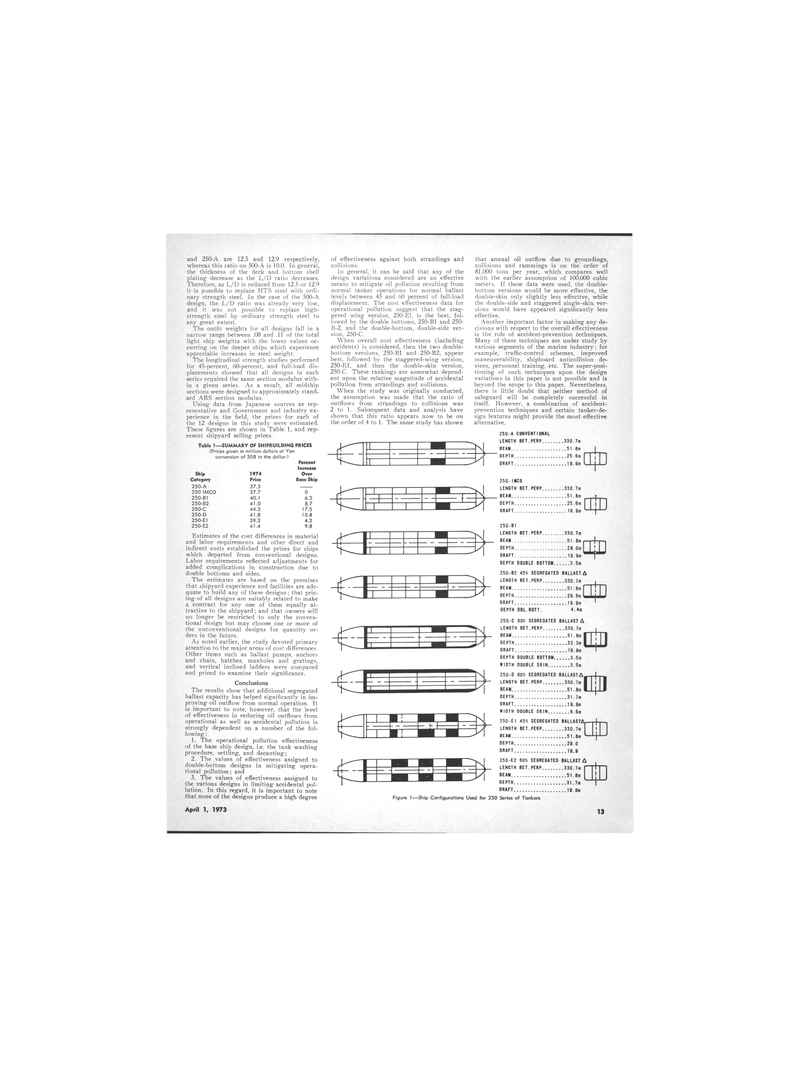

Many of these techniques are under study by various segments of the marine industry; for example, traffic-control schemes, improved maneuverability, shipboard anticollision de- vices, personnel training, etc. The super-posi~ tioning of such techniques upon the design variations in this paper is not possible and is beyond the scope to this paper. Nevertheless, there is little doubt that neither method of safeguard will be completely successful in itself. However, a combination of accident- prevention techniques and certain tanker-de- sign features might provide the most effective alternative. 250-A CONVENTIONAL

LENGTH BET.PERP 330.7m

BEAM 51.8

DEPTH 25.6m

DRAFT 19.9 250-IMC0

LENGTH BET.PERP 330.7m

BEAM. 51,8

DEPTH 25.6m

DRAFT 19.9 250-B1

LENGTH BET.PERP 330.7m

BEAM 51.8

DEPTH 28.0m

DRAFT .19:9

DEPTH DOUBLE BOTTOM 3.5m

OjD 250-B2 45« SEGREGATED BALLAST A

LENGTH BET.PERP 330.7m

BEAM 51:8

DEPTH 29.6m

DRAFT 19. 9m

DEPTH DBL.BOTT. 4.4m •fD 250-C 60% SEGREGATED BALLAST A

LENGTH BET.PERP 3,30.7m

BEAM 51 ,8m

DEPTH 32.3

DRAFT 19.8m

DEPTH DOUBLE, BOTTOM 3.5m

WIDTH DOUBLE SKIN 3.5m

ED ft 250-0 60% SEGREGATED BALLAST A.

LENGTH BET.PERP 330.7m

BEAM. 51.8

DEPTH 31.7m

DRAFT 1 9.9m

WIDTH DOUBLE SKIN 6.6m 250-E1 45% SEGREGATED BALLASTA

LENGTH BET.PERP 330.7m

BEAM. 51.8

DEPTH 29.0

DRAFT 19.9 250-E2 6054 SEGREGATED BALLAST A

LENGTH BET.PERP 330.7m

BEAM ..51.8

DEPTH 31.7m

DRAFT 19.9

Figure 1—Ship Configurations Used for 250 Series of Tankers

April 1, 1973 13

10

10

12

12