Page 38: of Maritime Reporter Magazine (April 15, 1973)

Read this page in Pdf, Flash or Html5 edition of April 15, 1973 Maritime Reporter Magazine

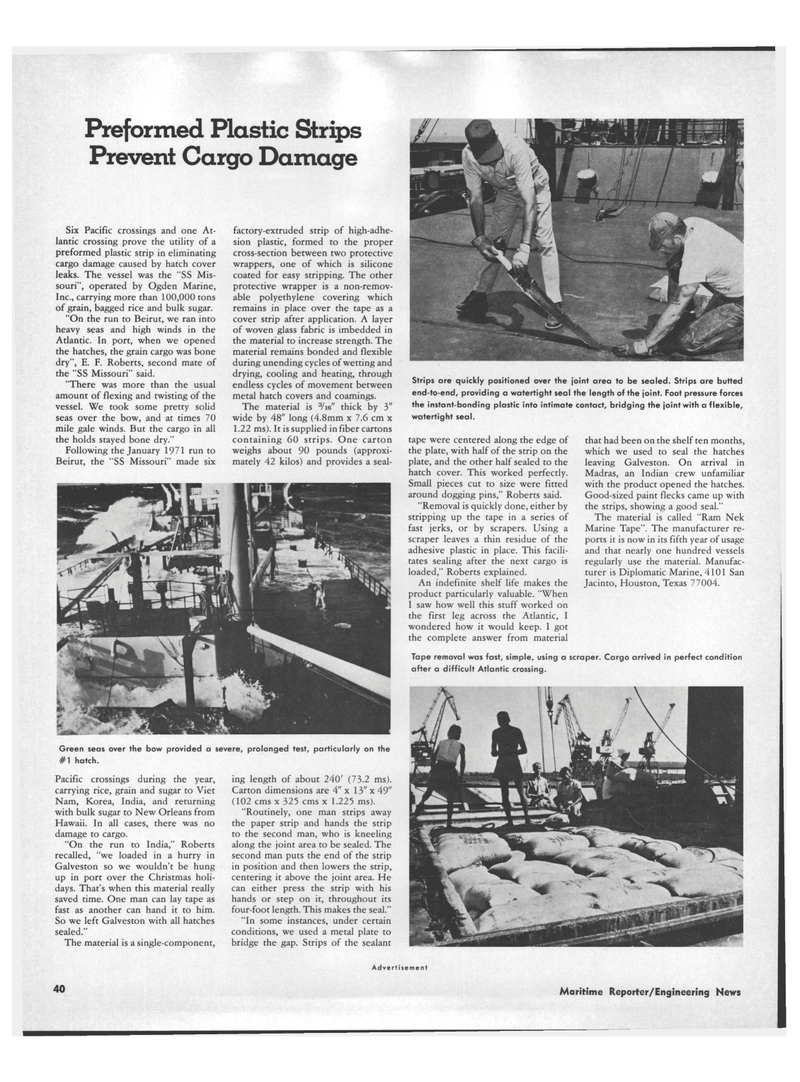

Strips are quickly positioned over the joint area to be sealed. Strips are butted end-to-end, providing a watertight seal the length of the joint. Foot pressure forces the instant-bonding plastic into intimate contact, bridging the joint with a flexible, watertight seal. tape were centered along the edge of the plate, with half of the strip on the plate, and the other half sealed to the hatch cover. This worked perfectly.

Small pieces cut to size were fitted around dogging pins," Roberts said. "Removal is quickly done, either by stripping up the tape in a series of fast jerks, or by scrapers. Using a scraper leaves a thin residue of the adhesive plastic in place. This facili- tates sealing after the next cargo is loaded," Roberts explained.

An indefinite shelf life makes the product particularly valuable. "When

I saw how well this stuff worked on the first leg across the Atlantic, I wondered how it would keep. I got the complete answer from material that had been on the shelf ten months, which we used to seal the hatches leaving Galveston. On arrival in

Madras, an Indian crew unfamiliar with the product opened the hatches.

Good-sized paint flecks came up with the strips, showing a good seal."

The material is called "Ram Nek

Marine Tape". The manufacturer re- ports it is now in its fifth year of usage and that nearly one hundred vessels regularly use the material. Manufac- turer is Diplomatic Marine, 4101 San

Jacinto, Houston, Texas 77004.

Tape removal was fast, simple, using a scraper. Cargo arrived in perfect condition after a difficult Atlantic crossing.

Preformed Plastic Strips

Prevent Cargo Damage

Green seas over the bow provided a severe, prolonged test, particularly on the #1 hatch.

Pacific crossings during the year, carrying rice, grain and sugar to Viet

Nam, Korea, India, and returning with bulk sugar to New Orleans from

Hawaii. In all cases, there was no damage to cargo. "On the run to India," Roberts recalled, "we loaded in a hurry in

Galveston so we wouldn't be hung up in port over the Christmas holi- days. That's when this material really saved time. One man can lay tape as fast as another can hand it to him.

So we left Galveston with all hatches sealed."

The material is a single-component, ing length of about 240' (73.2 ms).

Carton dimensions are 4" x 13" x 49" (102 cms x 325 cms x 1.225 ms). "Routinely, one man strips away the paper strip and hands the strip to the second man, who is kneeling along the joint area to be sealed. The second man puts the end of the strip in position and then lowers the strip, centering it above the joint area. He can either press the strip with his hands or step on it, throughout its four-foot length. This makes the seal." "In some instances, under certain conditions, we used a metal plate to bridge the gap. Strips of the sealant

Six Pacific crossings and one At- lantic crossing prove the utility of a preformed plastic strip in eliminating cargo damage caused by hatch cover leaks. The vessel was the "SS Mis- souri", operated by Ogden Marine,

Inc., carrying more than 100,000 tons of grain, bagged rice and bulk sugar. "On the run to Beirut, we ran into heavy seas and high winds in the

Atlantic. In port, when we opened the hatches, the grain cargo was bone dry", E. F. Roberts, second mate of the "SS Missouri" said. "There was more than the usual amount of flexing and twisting of the vessel. We took some pretty solid seas over the bow, and at times 70 mile gale winds. But the cargo in all the holds stayed bone dry."

Following the January 1971 run to

Beirut, the "SS Missouri" made six factory-extruded strip of high-adhe- sion plastic, formed to the proper cross-section between two protective wrappers, one of which is silicone coated for easy stripping. The other protective wrapper is a non-remov- able polyethylene covering which remains in place over the tape as a cover strip after application. A layer of woven glass fabric is imbedded in the material to increase strength. The material remains bonded and flexible during unending cycles of wetting and drying, cooling and heating, through endless cycles of movement between metal hatch covers and coamings.

The material is 3/le" thick by 3" wide by 48" long (4.8mm x 7.6 cm x 1.22 ms). It is supplied in fiber cartons containing 60 strips. One carton weighs about 90 pounds (approxi- mately 42 kilos) and provides a seal-

Advertisement 40 Maritime Reporter/Engineering News

37

37

39

39