Page 9: of Maritime Reporter Magazine (May 1973)

Read this page in Pdf, Flash or Html5 edition of May 1973 Maritime Reporter Magazine

OOO-cubic-meter LNG tankers for delivery in late 1974 and early 1976.

This order brings the total number of LNG tankers built and on order in accordance with the Technigaz design to 12.

Cryogenic Structures Corp. of

Northvale, N.J., an affiliate of Bal- tek Corp., announced that it has received a letter of intent from

Newport News Shipbuilding, un- der which Cryogenic will provide the balsa and plywood insulation panels used in the LNG tankers.

Total value of the insulation sys- tems for the .three tankers will be more than $20 million. Cryogenic

Structures is a licensee of Techni- gaz to manufacture and market in this country the panels used for in- sulation of membrane tanks in the

LNG carriers.

Meanwhile, Gotaas-Larsen, Inc. of New York, the shipping sub- sidiary of International Utilities

Corp., announced agreement with an international group of energy companies for a 20-year charter of three LNG carriers to be 'built in the Stavanger, Norway, yard of

Moss Rosenberg Verft. The char- ter period is to begin in 1976.

The three vessels will transport

LNG from Das Island and Abu

Dhabi in the Arabian Gulf to Ja- pan. These will be ships of 125,000- cubic-meter capacity, 960 feet in length, and with a draft of only 37 feet. This shallow draft, unusual in vessels of such size, will enable them to call at a number of ports not accessible to deep-draft oil tankers.

Companies involved in the char- ter agreement include British Pe- troleum Co., Ltd. of London, Com- pagnie Francaise des Petroles, Par- is ; Mitsui & Co., Ltd., Tokyo, and

Bridgestone Liquefied Gas Co.,

Ltd., also of Tokyo. The Japanese

Government has approved the ar- rangement.

API Appoints

Henry J. Luck Jr.

Henry J. Luck Jr.

Henry J. Luck Jr. has been ap- pointed chairman of the American

Petroleum Institute's central com- mittee on transportation by water.

This committee was created in 1934 to implement industry policy and provide technical input in do- mestic and international develop- ments affecting vessels and marine facilities.

Mr. Luck is a graduate of the

United States Merchant Marine

Academy and joined Mobil Oil

Corporation in 1949. He had held executive positions in various func- tions, and was named president of

Mobil Shipping and Transporta- tion Company, and general man- ager of Marine Transportation on

January 1, 1970.

Mr. Luck is also active in other industry organizations as a direc- tor of the American Institute of

Merchant Shipping, a director of

TOVALOP and CRISTAL, and a member of the executive commit- tee of the American Committee for

Flags of Necessity. $19.6-Million Order

For Two Cargoships

To Govan Shipbuilders

According to reports from Lon- don, Govan Shipbuilders Ltd., the Government-backed company which took over the Upper Clyde

Shipyard, has announced that it has received a $19.68-million order from the Kuwait Shipping Co. for two cargoships.

The company's yards now have an order book worth $146 million for 14 ships, Archie Gilchrist, chief executive, said.

The orders will enable Govan

Shipbuilders to maintain work into the first half of 1975.

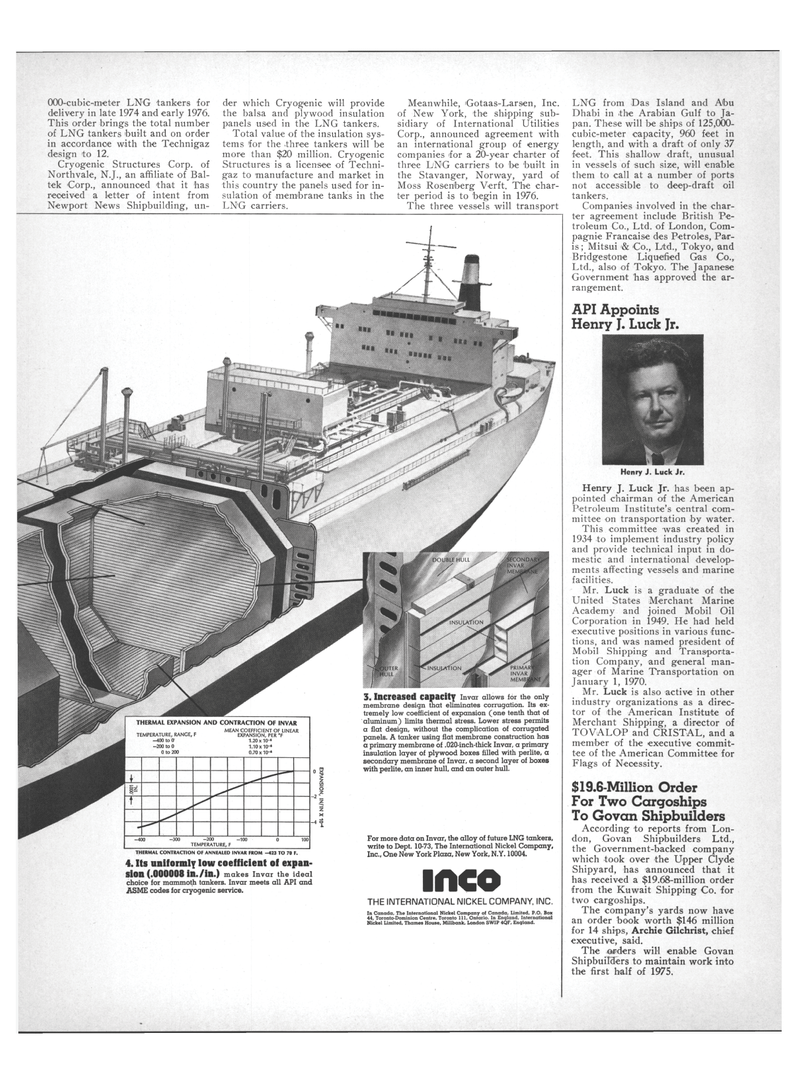

SfCONDAl

INVAR M MtMwm

DOUBIf HULL

INSUiXflON PRIMA

INVAR mf

MEMBBjP £ -300 -200 -100

TEMPERATURE, F

For more data on Invar, the alloy of future LNG tankers, write to Dept. 10-73, The International Nickel Company,

Inc., One New York Plaza, New York, N.Y. 10004.

IMO

THE INTERNATIONAL NICKEL COMPANY, INC.

In Canada, The International Nickel Company of Canada, Limited. P.O. Box 44, Toronto-Dominion Centre, Toronto 111, Ontario. In England. International

Nickel Limited, Thames House, MUlbank, London SWIP 4QF. England.

THERMAL EXPANSION AND CONTRACTION OF INVAR

MEAN COEFFICIENT OF LINEAR

EXPANSION, PER 'F 1.20x10"' 1.10x10"' 0.70 X10-' 4. Its uniformlY low coefficient of expan- sion (.000008 in./in.) makes Invar the ideal choice for mammoth tankers. Invar meets all API and

ASME codes for cryogenic service.

TEMPERATURE, RANGE, F —400 to 0' -200 toO 0 to 200 3. Increased capacity Invar allows for the only membrane design that eliminates corrugation. Its ex- tremely low coefficient of expansion (one tenth that of aluminum) limits thermal stress. Lower stress permits a flat design, without the complication of corrugated panels. A tanker using flat membrane construction has a primary membrane of .020-inch-thick Invar, a primary insulation layer of plywood boxes filled with perlite, a secondary membrane of Invar, a second layer of boxes with perlite, an inner hull, and an outer hull.

THERMAL CONTRACTION OF ANNEALED INVAR FROM -423 TO 70 F.

8

8

10

10