Page 12: of Maritime Reporter Magazine (May 1973)

Read this page in Pdf, Flash or Html5 edition of May 1973 Maritime Reporter Magazine

AquaMarine Awards $6 Vi -Million Contract

To Burton Shipyards

J.C. Garner, president of Burton

Shipyards, >Inc., Port Arthur, Tex- as, has announced the signing of a $6}4-million contract with Aqua-

Marine, Inc. of Houston for the construction of four advanced-de- sign tug/supply vessels. The keel will be laid for the first of these vessels this month, with comple- tion scheduled for November. The second vessel is scheduled for com- pletion in December. Mid-1974 completions are planned for the re- maining two vessels. "These triple-engine triple-screw vessels are designed for total serv- ice to the offshore rig—towing to location, positioning, anchor han- dling, supply. They are well-suited to perform any type of service needed by the offshore oil industry —anywhere in the world. Fast, powerful, versatile and seaworthy, these four are the type of 'work- horse' tug/supply vessel we have a reputation for building best," stated 'Mr. Garner.

Tom Gilbert, president of Aqua-

Marine, Inc., said that these ves- sels would give AquaMarine world- wide operational capabilities. On his recent visit to Europe and the

North Sea area, Mr. Gilbert sur- veyed the special requirements for tug/supply activities. He expressed

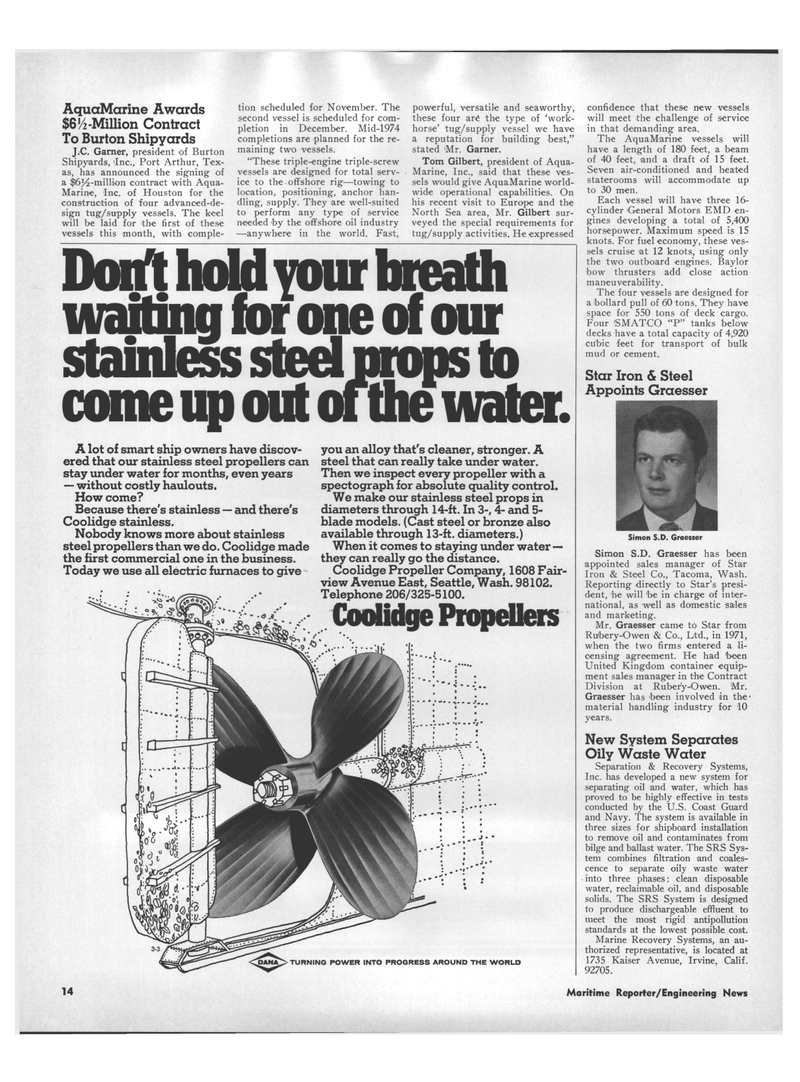

Dont hold your breath waiting for one of our stainless steel mops to come up out ofthe water.

A lot of smart ship owners have discov- ered that our stainless steel propellers can stay under water for months, even years — without costly haulouts.

How come?

Because there's stainless — and there's

Coolidge stainless.

Nobody knows more about stainless steel propellers than we do. Coolidge made the first commercial one in the business.

Today we use all electric furnaces to give you an alloy that's cleaner, stronger. A steel that can really take under water.

Then we inspect every propeller with a spectograph for absolute quality control.

We make our stainless steel props in diameters through 14-ft. In 3-, 4- and 5- blade models. (Cast steel or bronze also available through 13-ft. diameters.)

When it comes to staying under water — they can really go the distance.

Coolidge Propeller Company, 1608 Fair- view Avenue East, Seattle, Wash. 98102.

Telephone 206/325-5100.

Coolidge Propellers

DANA~> TURNING POWER INTO PROGRESS AROUND THE WORLD confidence that these new vessels will meet the challenge of service in that demanding area.

The AquaMarine vessels will have a length of 180 feet, a beam of 40 feet, and a draft of 15 feet.

Seven air-conditioned and heated staterooms will accommodate up to 30 men.

Each vessel will have three 16- cylinder 'General Motors EMD en- gines developing a total of 5,400 horsepower. Maximum speed is 15 knots. For fuel economy, these ves- sels cruise at 12 knots, using only the two outboard engines. Baylor bow thrusters add close action maneuverability.

The four vessels are designed for a bollard pull of 60 tons. They have space for 550 tons of deck cargo.

Four •SMATCO "P" tanks below decks have a total capacity of 4,920 cubic feet for transport of bulk mud or cement.

Star Iron & Steel

Appoints Graesser

Simon S.D. Graesser

Simon S.D. Graesser has been appointed sales manager of Star

Iron & Steel Co., Tacoma, Wash.

Reporting directly to Star's presi- dent, he will 'be in charge of inter- national, as well as domestic sales and marketing.

Mr. Graesser came to Star from

Rubery-Owen & Co., Ltd., in 1971, when the two firms entered a li- censing agreement. He had 'been

United Kingdom container equip- ment sales manager in the Contract

Division at Rubery-Owen. Mr.

Graesser has 'been involved in the- material handling industry for 10 years.

New System Separates

Oily Waste Water

Separation & Recovery Systems,

Inc. has developed a new system for separating oil and water, which has proved to be highly effective in tests conducted by the U.S. Coast Guard and Navy. The system is available in three sizes for shipboard installation to remove oil and contaminates from bilge and ballast water. The SRS Sys- tem combines filtration and coales- cence to separate oily waste water into three phases: clean disposable water, reclaimable oil, and disposable solids. The SRS System is designed to produce dischargeable effluent to meet the most rigid antipollution standards at the lowest possible cost.

Marine Recovery Systems, an au- thorized representative, is located at 1735 Kaiser Avenue, Irvine, Calif. 92705. 14 Maritime Reporter/Engineering News

11

11

13

13