Page 4: of Maritime Reporter Magazine (June 15, 1973)

Read this page in Pdf, Flash or Html5 edition of June 15, 1973 Maritime Reporter Magazine

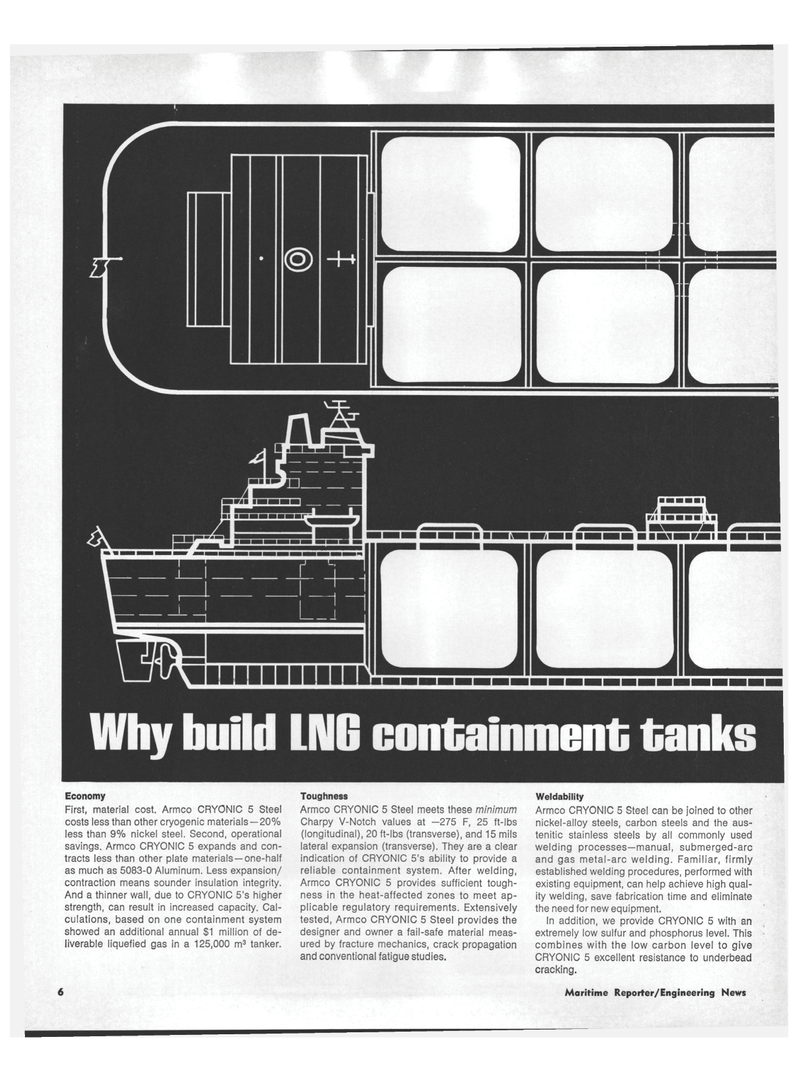

Why build ING containment tanks

Economy

First, material cost. Armco CRYONIC 5 Steel costs less than other cryogenic materials —20% less than 9% nickel steel. Second, operational savings. Armco CRYONIC 5 expands and con- tracts less than other plate materials —one-half as much as 5083-0 Aluminum. Less expansion/ contraction means sounder insulation integrity.

And a thinner wall, due to CRYONIC 5's higher strength, can result in increased capacity. Cal- culations, based on one containment system showed an additional annual $1 million of de- liverable liquefied gas in a 125,000 m3 tanker.

Toughness

Armco CRYONIC 5 Steel meets these minimum

Charpy V-Notch values at -275 F, 25 ft-lbs (longitudinal), 20 ft-lbs (transverse), and 15 mils lateral expansion (transverse). They are a clear indication of CRYONIC 5's ability to provide a reliable containment system. After welding,

Armco CRYONIC 5 provides sufficient tough- ness in the heat-affected zones to meet ap- plicable regulatory requirements. Extensively tested, Armco CRYONIC 5 Steel provides the designer and owner a fail-safe material meas- ured by fracture mechanics, crack propagation and conventional fatigue studies.

Weldability

Armco CRYONIC 5 Steel can be joined to other nickel-alloy steels, carbon steels and the aus- tenitic stainless steels by all commonly used welding processes—manual, submerged-arc and gas metal-arc welding. Familiar, firmly established welding procedures, performed with existing equipment, can help achieve high qual- ity welding, save fabrication time and eliminate the need for new equipment.

In addition, we provide CRYONIC 5 with an extremely low sulfur and phosphorus level. This combines with the low carbon level to give

CRYONIC 5 excellent resistance to underbead cracking. 6 Maritime Reporter/Engineering News

3

3

5

5