Page 9: of Maritime Reporter Magazine (October 1973)

Read this page in Pdf, Flash or Html5 edition of October 1973 Maritime Reporter Magazine

er seagoing vessels. The facility- has more than a quarter-of-a-million square feet of covered working area and a 1,700 by 500 foot building and launching slip.

The latest addition to Marathon's marine capabilities is the former

John Brown Shipyards on 61 acres of the River Clyde at 'Clydebank near Glasgow, Scotland. These shipyards were acquired in mid- 1972 and immediately brought on stream to better service the petro- leum industry's exploration of un- derwater reserves in the North

Sea. Total reconstruction of the facilities, where the noted Queen

Elizabeth liners were built, was undertaken concurrently with the start-up of construction on the firsit two offshore drilling platforms commissioned for the yard.

With expansion underway, the

Marathon Scotland Shipyard will have the capability of constructing and fabricating several vessels and offshore platforms simultaneously.

A fully equipped machine shop, steel-fabrication shop, hydraulic transfer and launch system and crane systems for ship construction will make the Marathon yard one of the most moderh in the industry.

At the Marine Division, Vicks- burg, Miss., Marathon manufac- tures mobile offshore-drilling plat- forms, operational in depths well beyond the limits of Other bottom- supported equipment. Distinguish- ing features of these platforms are high mobility, self-contained de- sign, self-elevating, open-truss legs and rugged hull construction, con- tinuous bearing tank and mat de- velopment. The site includes 426,000 square feeit of manufactur- ing area and 2,769 acres. Also manufactured here are other ma- rine and heavy handling equipment, gear reductions and heavy forg- ings.

Marathon Shipbuilding is located on a 1,000-fooit frontage at the

Vickslburg Harbor Canal. Since it opened its doors in 1965, the yard has built towboats, offshore supply vessels, barges and work-over drill- ing rigs among other products. On its dry dock, the firm has repaired oceangoing vessels, towboats and a variety of floating equipment.

The dry dock is 65 feet between wing walls and 130 feet in length.

Strategically located adjacent to the Port of A^ickslburg, Marathon

Shipbuilding has lifting capabili- ties of up to 125 tons, which allows the yard to specialize in marine construction and fabrication.

Marathon Offshore PTE., Ltd. in the Republic of Singapore has completely new and modern facili- ties on 35 acres and a 2,370-foot deep-water frontage. With over 800 highly trained and experienced employees, this facility features covered, fully integrated fabrica- tion areas as well as concrete launching facilities for self-elevat- ing platforms and other vessels and marine equipment. The fa- cility is equipped and manned to handle everything from the small- est repair or maintenance job to the construction of oceangoing vessels and floating stock.

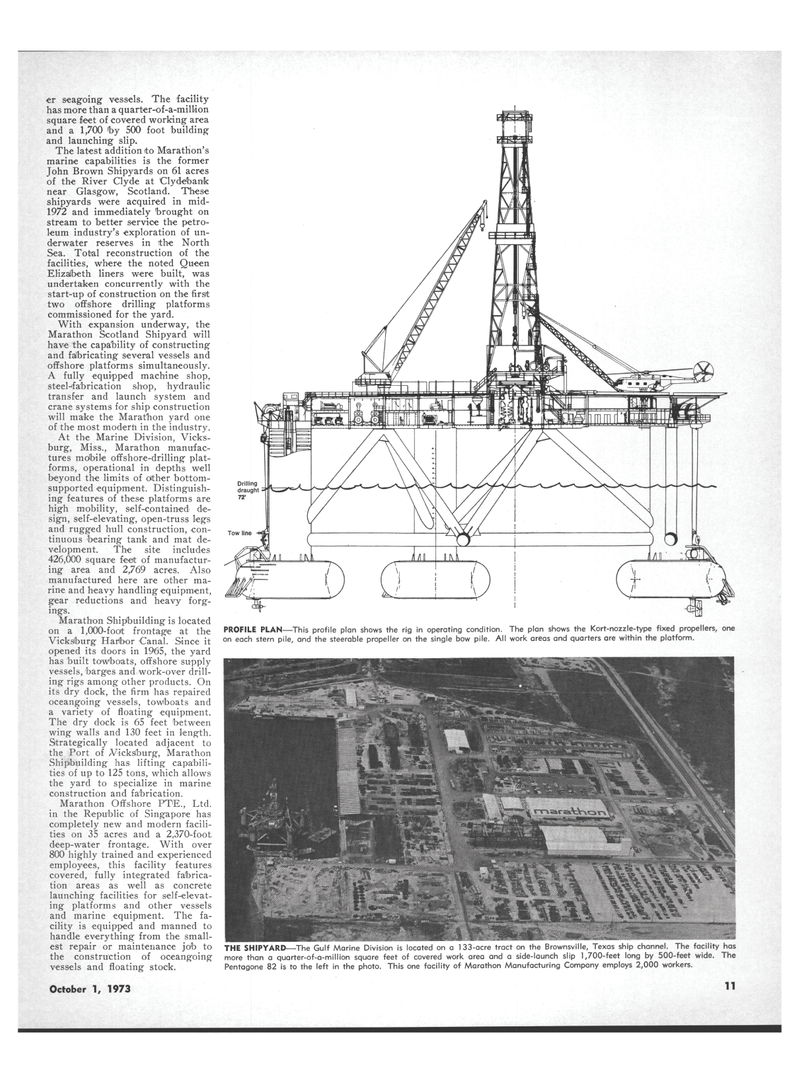

PROFILE PLAN—This profile plan shows the rig in operating condition. The plan shows the Kort-nozzle-type fixed propellers, one on each stem pile, and the steerable propeller on the single bow pile. All work areas and quarters are within the platform.

THE SHIPYARD—The Gulf Marine Division is located on a 133-acre tract on the Brownsville, Texas ship channel. The facility has more than a quarter-of-a-million square feet of covered work area and a side-launch slip 1,700-feet long by 500-feet wide. The

Pentagone 82 is to the left in the photo. This one facility of Marathon Manufacturing Company employs 2,000 workers.

October 1, 1973 11

8

8

10

10