Page 34: of Maritime Reporter Magazine (October 15, 1973)

Read this page in Pdf, Flash or Html5 edition of October 15, 1973 Maritime Reporter Magazine

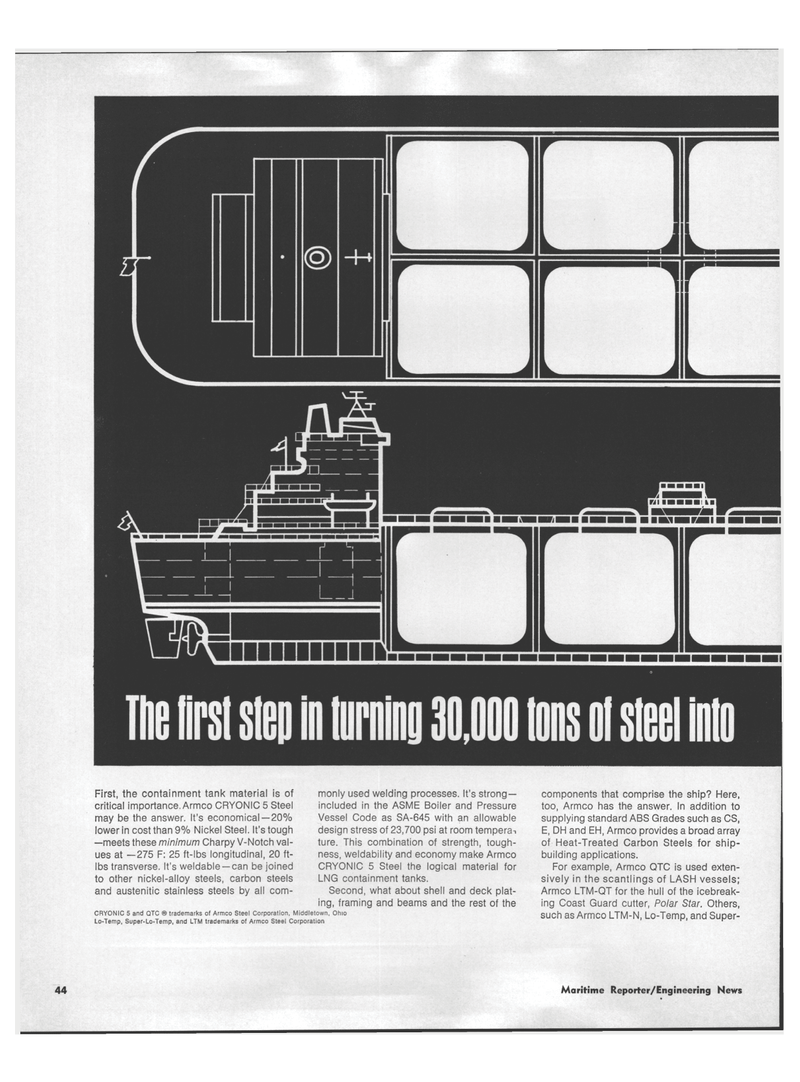

The first step in turning 30,000 ions oi steel into

First, the containment tank material is of critical importance. Armco CRYONIC 5 Steel may be the answer. It's economical —20% lower in cost than 9% Nickel Steel. It's tough —meets these minimum Charpy V-Notch val- ues at —275 F: 25 ft-lbs longitudinal, 20 ft-

Ibs transverse. It's weldable —can be joined to other nickel-alloy steels, carbon steels and austenitic stainless steels by all com- monly used welding processes. It's strong — included in the ASME Boiler and Pressure

Vessel Code as SA-645 with an allowable design stress of 23,700 psi at room temperai ture. This combination of strength, tough- ness, weldability and economy make Armco

CRYONIC 5 Steel the logical material for

LNG containment tanks.

Second, what about shell and deck plat- ing, framing and beams and the rest of the

CRYONIC 5 and QTC ® trademarks of Armco Steel Corporation, Middletown, Ohio

Lo-Temp, Super-Lo-Temp, and LTM trademarks of Armco Steel Corporation components that comprise the ship? Here, too, Armco has the answer. In addition to supplying standard ABS Grades such as CS,

E, DH and EH, Armco provides a broad array of Heat-Treated Carbon Steels for ship- building applications.

For example, Armco QTC is used exten- sively in the scantlings of LASH vessels;

Armco LTM-QT for the hull of the icebreak- ing Coast Guard cutter, Polar Star. Others, such as Armco LTM-N, Lo-Temp, and Super- 14 Maritime Reporter/Engineering News

33

33

35

35