Page 40: of Maritime Reporter Magazine (November 15, 1973)

Read this page in Pdf, Flash or Html5 edition of November 15, 1973 Maritime Reporter Magazine

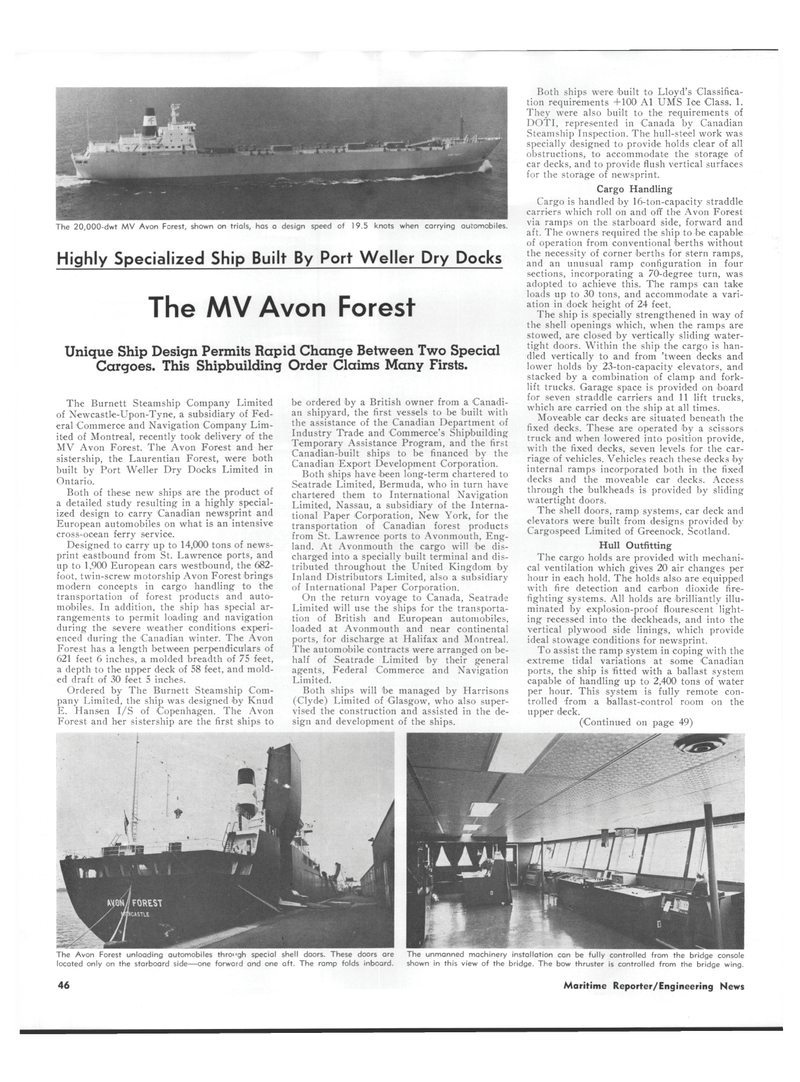

The 20,000-dwt MV Avon Forest, shown on trials, has a design speed of 19.5 knots when carrying automobiles.

Highly Specialized Ship Built By Port Weller Dry Docks

The AAV Avon Forest

Unique Ship Design Permits Rapid Change Between Two Special

Cargoes. This Shipbuilding Order Claims Many Firsts.

The Burnett Steamship Company Limited of Newcastle-Upon-Tyne, a subsidiary of Fed- eral Commerce and Navigation Company Lim- ited of Montreal, recently took delivery of the

MV Avon Forest. The Avon Forest and her sistership, the Laurentian Forest, were both built by Port Weller Dry Docks Limited in

Ontario.

Both of these new ships are the product of a detailed study resulting in a highly special- ized design to carry Canadian newsprint and

European automobiles on what is an intensive cross-ocean ferry service.

Designed to carry up to 14,000 tons of news- print eastbound from St. Lawrence ports, and up to 1,900 European cars westbound, the 682- foot, twin-screw motorship Avon Forest brings modern concepts in cargo handling to the transportation of forest products and auto- mobiles. In addition, the ship has special ar- rangements to permit loading and navigation during the severe weather conditions experi- enced during the Canadian winter. The Avon

Forest has a length between perpendiculars of 621 feet 6 inches, a molded breadth of 75 feet, a depth to the upper deck of 58 feet, and mold- ed draft of 30 feet 5 inches.

Ordered by The Burnett Steamship Com- pany Limited, the ship was designed by Knud

E. Hansen I/S of Copenhagen. The Avon

Forest and her sistership are the first ships to be ordered by a British owner from a Canadi- an shipyard, the first vessels to be built with the assistance of the Canadian Department of

Industry Trade and Commerce's Shipbuilding

Temporary Assistance Program, and the first

Canadian-built ships to be financed by the

Canadian Export Development Corporation.

Both ships have been long-term chartered to

Seatrade Limited, Bermuda, who in turn have chartered them to International Navigation

Limited, Nassau, a subsidiary of the Interna- tional Paper Corporation, New York, for the transportation of Canadian forest products from St. Lawrence ports to Avonmouth, Eng- land. At Avonmouth the cargo will be dis- charged into a specially built terminal and dis- tributed throughout the United Kingdom by

Inland Distributors Limited, also a subsidiary of International Paper Corporation.

On the return voyage to Canada, Seatrade

Limited will use the ships for the transporta- tion of British and European automobiles, loaded at Avonmouth and near continental ports, for discharge at Halifax and Montreal.

The automobile contracts were arranged on be- half of Seatrade Limited by their general agents, Federal Commerce and Navigation

Limited.

Both ships will be managed by Harrisons (Clyde) Limited of Glasgow, who also super- vised the construction and assisted in the de- sign and development of the ships.

Both ships were built to Lloyd's Classifica- tion requirements +100 A1 UMS Ice Class. 1.

They were also built to the requirements of

DOTI, represented in Canada by Canadian

Steamship Inspection. The hull-steel work was specially designed to provide holds clear of all obstructions, to accommodate the storage of car decks, and to provide flush vertical surfaces for the storage of newsprint.

Cargo Handling

Cargo is handled by 16-ton-capacity straddle carriers which roll on and off the Avon Forest via ramps on the starboard side, forward and aft. The owners required the ship to be capable of operation from conventional berths without the necessity of corner berths for stern ramps, and an unusual ramp configuration in four sections, incorporating a 70-degree turn, was adopted to achieve this. The ramps can take loads up to 30 tons, and accommodate a vari- ation in dock height of 24 feet.

The ship is specially strengthened in way of the shell openings which, when the ramps are stowed, are closed by vertically sliding water- tight doors. Within the ship the cargo is han- dled vertically to and from 'tween decks and lower holds by 23-ton-capacity elevators, and stacked by a combination of clamp and fork- lift trucks. Garage space is provided on board for seven straddle carriers and 11 lift trucks, which are carried on the ship at all times.

Moveable car decks are situated beneath the fixed decks. These are operated by a scissors truck and when lowered into position provide, with the fixed decks, seven levels for the car- riage of vehicles. Vehicles reach these decks by internal ramps incorporated both in the fixed decks and the moveable car decks. Access through the bulkheads is provided by sliding watertight doors.

The shell doors, ramp systems, car deck and elevators were built from designs provided by

Cargospeed Limited of Greenock, Scotland.

Hull Outfitting

The cargo holds are provided with mechani- cal ventilation which gives 20 air changes per hour in each hold. The holds also are equipped with fire detection and carbon dioxide fire- fighting systems. All holds are brilliantly illu- minated by explosion-proof fiourescent light- ing recessed into the deckheads, and into the vertical plywood side linings, which provide ideal stowage conditions for newsprint.

To assist the ramp system in coping with the extreme tidal variations at some Canadian ports, the ship is fitted with a ballast system capable of handling up to 2,400 tons of water per hour. This system is fully remote con- trolled from a ballast-control room on the upper deck. (Continued on page 49)

The unmanned machinery installation can be fully controlled from the bridge console shown in this view of the bridge. The bow thruster is controlled from the bridge wing.

The Avon Forest unloading automobiles throi'gh special shell doors. These doors are located only on the starboard side—one forward and one aft. The ramp folds inboard. 46 Maritime Reporter/Engineering News

39

39

41

41