Page 25: of Maritime Reporter Magazine (January 15, 1974)

Read this page in Pdf, Flash or Html5 edition of January 15, 1974 Maritime Reporter Magazine

Shipbuilders Council Of America

Year-End Report

Edwin M. Hood

The rapid momentum of Ameri- can shipbuilding-, initiated with the enactment of legislation in 1970 (the Merchant Marine Act of 1970), designed to restore the Unit- ed States to a position of promi- nence and substance among world maritime powers, continued to ac- celerate in 1973.

Edwin M. Hood, President

Shipbuilders Council of America

International economic and mon- etary developments, in conjunction with cost saving emphasis domes- tically, have furthermore prompted an eventful and partial closing of the differential between U.S. and foreign shipbuilding costs and prices. New lows in levels of Fed- eral construction subsidy support for tankers and liquefied natural gas (LNG) carriers have thus re- sulted during 1973. For the same reasons, many U.S. yards received merchant ship repair work which otherwise would have been done abroad.

During the year, merchant ship construction contracts totaling 38 vessels of 2,636,000 dwt have been placed with American yards. The aggregate value of these orders is estimated at slightly more than $1.5 billion. About 40 percent of these contracts are supported by

Federal subsidy funding. In addi- tion, U.S. shipyards have on order contracts for 35 offshore oil drilling rigs;

Simultaneously, appropriations for U.S. naval ship construction reached a new high of approxi- mately $3.5 billion. Most of these funds have financed the cost of in- cremental stages of earlier building contracts for submarines, destroy- ers, aircraft carriers and other ves- sels, including sophisticated elec- tronics and armaments. Only one procurement for a new naval ship program was awarded in 1973: the lead ship contract of a 50-ship innovative Patrol Frigate (PF) program. Also, a greater volume of Navy ship repair work has been placed with shipyards in the pri- vate sector.

This crescendo of activity has contributed to an unprecedented peacetime backlog of work in U.S. shipyards. Capital improvements have increased substantially. Ca- pacity has been improved accord- ingly, and additional expansion of production facilities has progressed beyond the planning stage. Produc- tivity of individual shipyard work- ers has reached new levels of proficiency and is said to be on a par with that in other countries.

On the other hand, profit margins, in many instances, have left much to be desired.

U.S. tanker building capacity, in particular, is anticipated to expand further from the present annual level of approximately 1,500,000 dwt to considerably more than 3,000,000 dwt in 1978. Some of this capacity will be devoted to the construction of very large crude carriers (VLCC's) of 400,000 dwt or larger, and a maximum eventual output of six or seven VLCC's an- nually would not seem unrealistic.

Along with the balance of Ameri- can industry, the U.S. shipbuilding industry, at the start of the New

Year, faces an array of problems, challenges and opportunities far different from the past. More and more, the conduct and planning of shipyard activity will be influenced by energy and environmental con- siderations as well as by geopoliti- cal, economic, governmental and •management actions.

The report of the Commission on

American Shipbuilding, released in mid-October, concluded that the

U.S. shipbuilding industry, given "the opportunity to build ships in series" and "a reasonable stability in its orderbook," is "fully capable of equalling the production efficien- cy in any foreign shipbuilding in- dustry for the construction of simi- lar ships." This Congressionally- mandated, Presidentially-appointed

Commission was chartered in 1970 to "review the status of the Ameri- can shipbuilding industry, its prob- lems and its progress toward in- creasing its productivity and re- ducing production costs." The ver- dict was unqualifiedly complimen- tary in terms of shipyard opera- tions and technology, capital im- provements, productivity, and la- bor-management relations.

The importance of ship financ- ing to ship construction was espe- cially emphasized by the Commis- sion. The "U.S. Ship Financing

Package," it was stated, "is sub- stantially better than any alterna- tive financing available for the con- struction and acquisition of foreign built ships." Domestic and foreign groups have to date combined and employed this "Package" in an ef- fective manner. Desirable contracts for U.S. shipyards have resulted.

Other prospects are now in various stages of negotiation, and should soon materialize as firm orders.

Even more, the Commission's re- port supported the concept of a limited cargo preference for U.S. flag, U.S. built tankers—a subject which, despite the ambiguities of present-day world oil diplomacy, has generated considerable favora- ble discussion in recent months.

Out of the Yom Kippur conflict in the Middle East, the concurrent posture of U.S.-NATO relations, and the ensuing Arab oil boycott, the inherent belief that the United

States must establish and maintain positive control over a reasonable portion of available transportation resources has re-emerged in public view with substantial impact. Po- tential future effects in terms of tanker requirements and new build- ing are now being realistically weighed.

Shipbuilding opportunities in the

United States will, of course, con- tinue to have a direct relationship to the prosperity, reliability and stability of the American flag mer- chant marine, to the expanding missions of the United States Na- vy, to requirements for oil and gas tankers to transport energy sup- plies from Alaska and elsewhere, and to needs for specialized vessels and floating equipment (drilling rigs, barges, mining ships, research vessels, and so on).

Shipyard management objec- tives, financing and contract condi- tions, production planning, steel throughput, material and compo- nent availabilities, existing work- load, and other factors, will con- tinue to govern decisions of indi- vidual shipbuilders to participate in these kinds of markets and to undertake additional contracts.

Nevertheless, American shipyards remain firm in the conviction that capacity will expand in direct pro- portion to demands for new ships and that the 1973 impetus will car- ry the industry on to greater ac- complishments in the coming year.

N.Y. SNAME, NYPE, IME And ASNE Joint Meeting

Hears Paper On Silencing Marine Gas Turbines

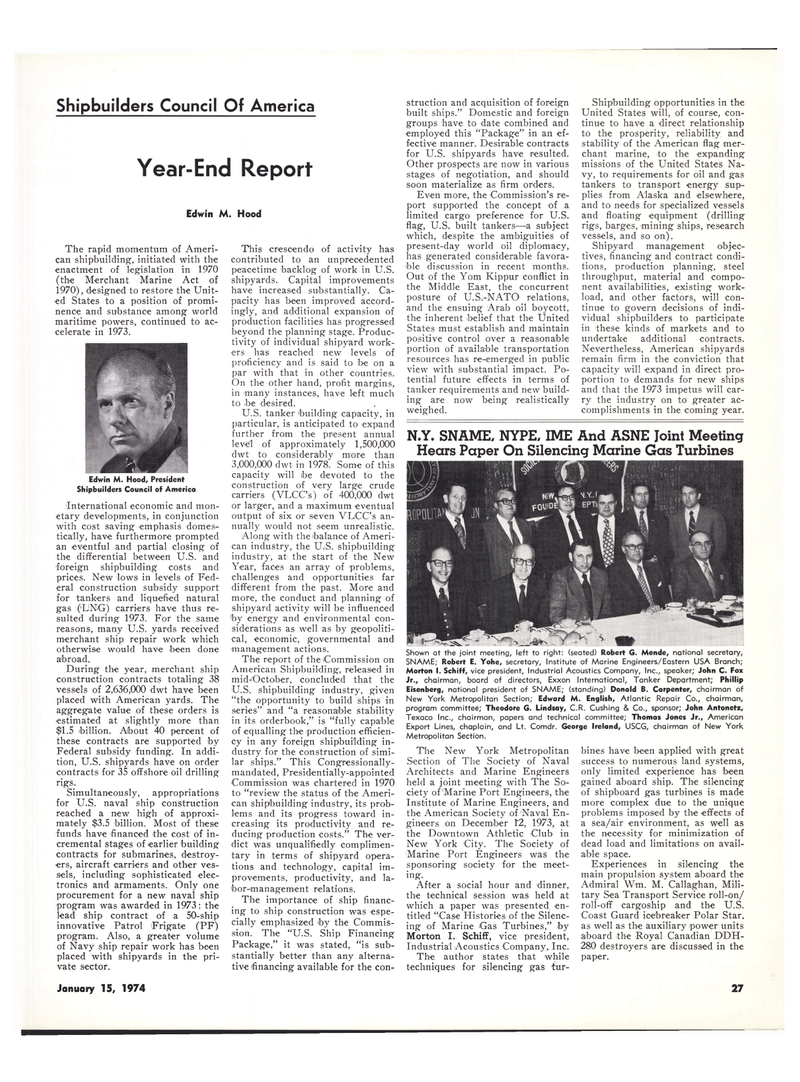

Shown at the joint meeting, left to right: (seated) Robert G. Mende, national secretary,

SNAME; Robert E. Yohe, secretary, Institute of Marine Engineers/Eastern USA Branch;

Morton I. Schiff, vice president, Industrial Acoustics Company, Inc., speaker; John C. Fox

Jr., chairman, board of directors, Exxon International, Tanker Department; Phillip

Eisenberg, national president of SNAME; (standing) Donald B. Carpenter, chairman of

New York Metropolitan Section; Edward M. English, Atlantic Repair Co., chairman, program committee; Theodore G. Lindsay, C.R. Cushing & Co., sponsor; John Antonetz,

Texaco Inc., chairman, papers and technical committee; Thomas Jones Jr., American

Export Lines, chaplain, and Lt. Comdr. George Ireland, USCG, chairman of New York

Metropolitan Section.

The New York Metropolitan

Section of The Society of Naval

Architects and Marine Engineers held a joint meeting with The So- ciety of'Marine Port Engineers, the

Institute of Marine Engineers, and the American Society of Naval En- gineers on December 1'2, 1973, at the Downtown Athletic Club in

New York City. The Society of

Marine Port Engineers was the sponsoring society for the meet- ing.

After a social hour and dinner, the technical session was held at which a paper was presented en- titled "Case Histories of the Silenc- ing of Marine Gas Turbines," by

Morton I. Schiff, vice president,

Industrial Acoustics Company, Inc.

The author states that while techniques for silencing gas tur- bines have been applied with great success to numerous land systems, only limited experience has been gained aboard ship. The silencing of shipboard gas turbines is made more complex due to the unique problems imposed by the effects of a sea/air environment, as well as the necessity for minimization of dead load and limitations on avail- able space.

Experiences in silencing the main propulsion system aboard the

Admiral Win. M. Callaghan, Mili- tary Sea Transport Service roll-on/ roll-off cargoship and the U.S.

Coast Guard icebreaker Polar Star, as well as the auxiliary power units aboard the Royal Canadian DDH- 280 destroyers are discussed in the paper.

January 15, 1974 27

24

24

26

26