Page 14: of Maritime Reporter Magazine (February 1974)

Read this page in Pdf, Flash or Html5 edition of February 1974 Maritime Reporter Magazine

Esso Norway Tests— (Continued from page 14)

Structural response caused by pressure sys- tems on tank boundaries must be compared to a condition with zero pressure on tank boundaries in order to get absolute values. This meant that, under conditions of zero trim, the internal pressures on the boundaries of tank groups Nos. 2, 3, and 4 (except for the forward boundary of No. 2 and the after boundary of

No. 4) must be matched by the external pres-

sures governed by the draft. Expressed other-

wise, this meant that the height of water bal-

last in all tanks in groups Because this combination of drafts and tank

loadings formed the base with which all read-

ings of instruments were compared, this con-

dition was called a "base run."

Ideally, if the structure were affected only

by pressures, only one base run would be

needed. In reality, however, there are a num-

ber of other influences which affect the in-

strument readings which measure structural

response. Some of these are:

1. Thermal Influence. The phenomenon of

thermal stress is well-known, and the fact that

it is powerfully affected by radiation from the

sky had to be considered in planning the

test program. Time limitations led to the de-

cision to operate the test schedule on a con-

tinuous round-the-clock basis, without regard

to the ambient weather conditions at the time

of the instrument reading. In addition to the

temperature effects on the steel of the struc-

ture, temperature obviously has some effect

on the cabling of the instrumentation system

itself.

2. Instrument Drift. Instrument systems

normally show some drift, that is. continuous

change with time, even with the best com-

pensation available. Thus, in comparing the

readings of a test run with those of a base run,

the shorter the time interval separating the

two runs, the more reliable the results should

be.

3. Shakedown. The structure itself in some

areas is subject to sequential instabilities,

often characterized by the words snap-througii

or oil-canning. This means that a nominally

plane plate may exhibit a bulge to one side

at one time, and at another time under exactly

the same conditions of loading may exhibit a

bulge of another character, usually on the oth-

er side. Phenomena such as this characterize

structural "shakedown" and may be presumed

to gradually disappear as the structure under-

goes a series of loadings and unloadings and

finally assumes its ultimate form.

These three influences and some others less

important led to the decision to intersperse

among the sequence of test runs a number of

base runs instead of depending on a single

base run.

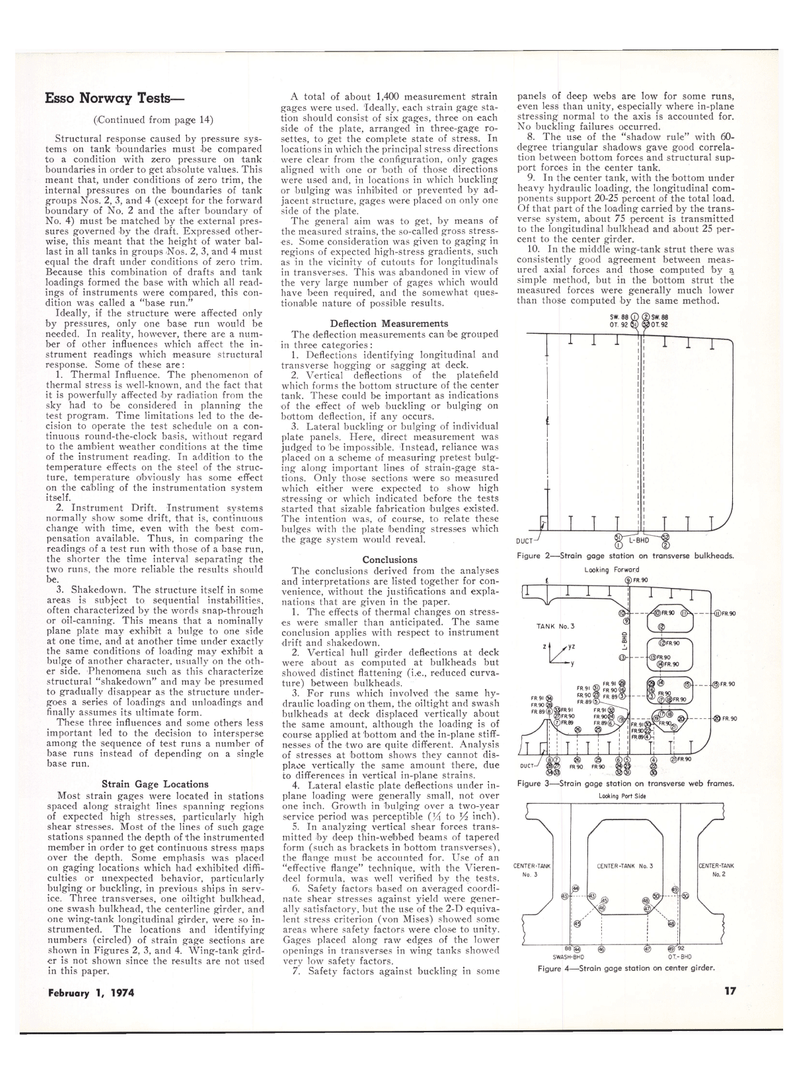

Strain Gage Locations

Most strain gages were located in stations

spaced along straight lines spanning regions

of expected high stresses, particularly high

shear stresses. Most of the lines of such gage

stations spanned the depth of the instrumented

member in order to get continuous stress maps

over the depth. Some emphasis was placed

on gaging locations which had exhibited diffi-

culties or unexpected behavior, particularly

bulging or buckling, in previous ships in serv-

ice. Three transverses, one oiltight bulkhead,

one swash bulkhead, 'the centerline girder, and

one wing-tank longitudinal girder, were so in-

strumented. The locations and identifying

numbers (circled) of strain gage sections are

shown in Figures 2, 3, and 4. Wing-tank gird-

er is not shown since the results are not used

in this paper.

A total of about 1,400 measurement strain

gages were used. 'Ideally, each strain gage sta-

tion should consist of six gages, three on each

side of the plate, arranged in three-gage ro-

settes, to get the complete state of stress. In

locations in which the principal stress directions

were clear from the configuration, only gages

aligned with one or both of those directions

were used and, in locations in which buckling

or bulging was inhibited or prevented by ad-

jacent structure, gages were placed on only one

side of the plate.

The general aim was to get, by means of

the measured strains, the so-called gross stress-

es. Some consideration was given to gaging in

regions of expected high-stress gradients, such

as in the vicinity of cutouts for longitudinals

in transverses. This was abandoned in view of

the very large number of gages which would

have been required, and the somewhat ques-

tionable nature of possible results.

Deflection Measurements

The deflection measurements can be grouped

in three categories:

1. Deflections identifying longitudinal and

transverse hogging or sagging a't deck.

2. Vertical deflections of the platefield

which forms the bottom structure of the center

tank. These could be important as indications

of the effect of web buckling or bulging on

bottom deflection, if any occurs.

3. Lateral buckling or bulging of individual

plate panels. Here, direct measurement was

judged to be impossible. Instead, reliance was

placed on a scheme of measuring pretest bulg-

ing along important lines of strain-gage sta-

tions. Only those sections were so measured

which either were expected to show high

stressing or which indicated before the tests

started that sizable fabrication bulges existed.

The intention was, of course, to relate these

bulges with the plate bending stresses which

the gage system would reveal.

Conclusions

The conclusions derived from the analyses

and interpretations are listed together for con-

venience, without the justifications and expla-

nations that are given in the paper.

1. The effects of thermal changes on stress-

es were smaller than anticipated. The same

conclusion applies with respect to instrument

drift and shakedown.

2. Vertical hull girder deflections at deck

were about as computed at bulkheads but

showed distinct flattening (i.e., reduced curva-

ture) between bulkheads.

3. For runs which involved the same hy-

draulic l-oading on 'them, the oiltight and swash

bulkheads at deck displaced vertically about

the same amount, although the loading is of

course applied at bottom and the in-plane stiff-

nesses of the two are quite different. Analysis

of stresses at bottom shows they cannot dis-

place vertically the same amount there, due

to differences in vertical in-plane strains.

4. Lateral elastic plate deflections under in-

plane loading were generally small, not over

one inch. Growth in bulging over a two-year

service period was perceptible (j4 to Yz inch).

5. In analyzing vertical shear forces trans-

mitted by deep thin-webbed beams of tapered

form (such as brackets in bottom transverses),

the flange must be accounted for. Use of an

"effective flange" technique, with the Vieren-

deel formula, was well verified by the tests.

6. Safety factors based on averaged coordi-

nate shear stresses against yield were gener-

ally satisfactory, but the use of the 2-D equiva-

lent stress criterion (von Mises) showed some

areas where safety factors were close to unity.

Gages placed along raw edges of the lower

openings in transverses in wing tanks showed

very low safety factors.

7. Safety factors against buckling in some

panels of deep webs are low for some runs,

even less than unity, especially where in-plane

stressing normal to the axis is accounted for.

No buckling failures occurred.

8. The use of the "shadow rule" with 60-

degree triangular shadows gave good correla-

tion between bottom forces and structural sup-

port forces in the center tank.

9. In the center tank, with the bottom under

heavy hydraulic loading, the longitudinal com-

ponents support 20-25 percent of the total load.

Of that part of the loading carried by the trans-

verse system, about 75 percent is transmitted

to the longitudinal bulkhead and about 25 per-

cent to the center girder.

10. In the middle wing-tank strut there was

consistently good agreement between meas-

ured axial forces and those computed by a

simple method, but in the bottom strut the

measured forces were generally much lower

than those computed by the same method.

r-r-T

DUCT

L±V

Figure 2—Strain gage station on transverse bulkheads.

Looking Forward

©FR.90

-©FR.90

(g>| j FR90

(g)®FR.90 J

~ FR.90

Figure 3—Strain gage station on transverse web frames.

Looking Port Side

CENTER-TANK

No. 3

CENTER-TANK No. 3

t©

1§> ®

CENTER-TANK

No. 2

92

0T.-BHD SWASH-BHD

Figure 4—Strain gage station on center girder.

February 1, 1974 17

13

13

15

15