Page 28: of Maritime Reporter Magazine (February 1974)

Read this page in Pdf, Flash or Html5 edition of February 1974 Maritime Reporter Magazine

Eleusis Shipyards Launches

Largest Vessel Built In Greece

On December 12, 1973, the first of a series of 43,300-deadweight-ton bulk carriers, the

Althea, was launched at Eleusis Shipyards

S.A. This is the biggest ship ever built in

Greece.

Eleusis Shipyards commenced operations in

August 1969, and since then the yard has progressed rapidly. The facilities have been extended, and the equipment has been im- proved by the acquisition of the most modern niachinery.

In the first phase of its development, the yard confined itself to repair and conversion work, and its business in these fields expanded.

Last year, the order book for repairs and con- versions grew at a particularly fast pace: be- tween January 1 and November 30, 1973, re- pairs were carried out on 148 vessels with a total tonnage of 2,153,000 grt.

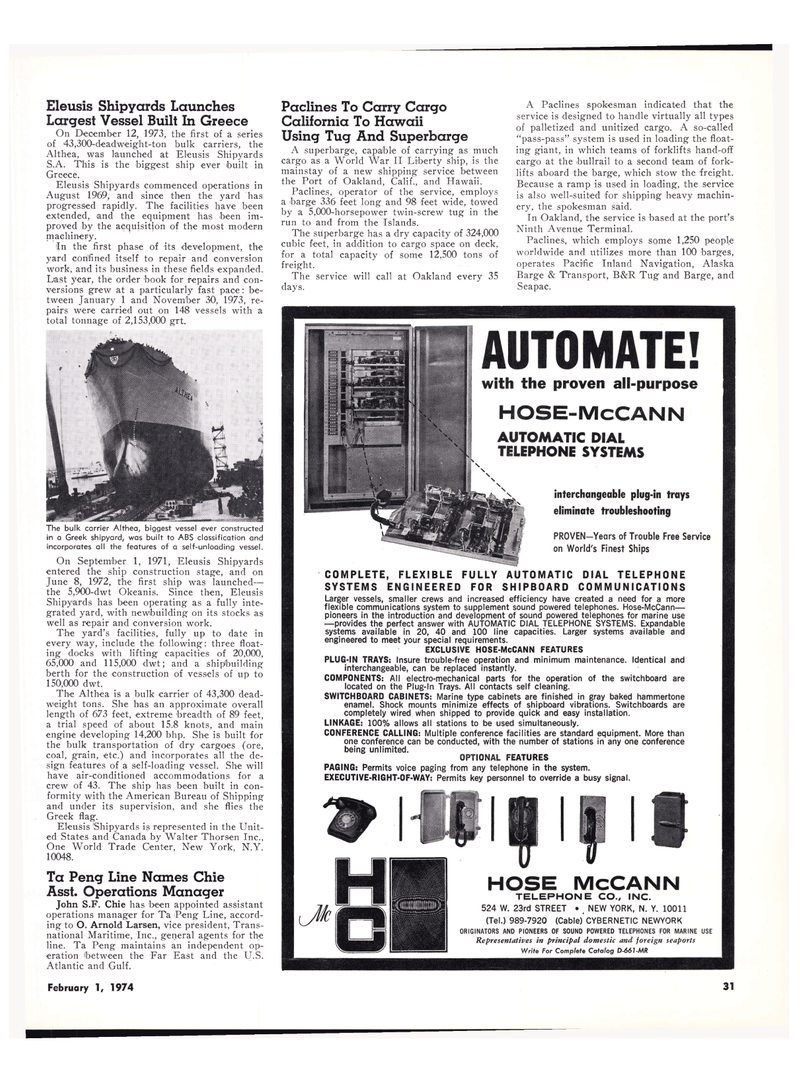

The bulk carrier Althea, biggest vessel ever constructed in a Greek shipyard, was built to ABS classification and incorporates all the features of a self-unloading vessel.

On September 1, 1971, Eleusis Shipyards entered the ship construction stage, and on

June 8, 1972, the first ship was launched— the 5,900-dwt Okeanis. Since then, Eleusis

Shipyards has been operating as a fully inte- grated yard, with newbuilding on its stocks as well as repair and conversion work.

The yard's facilities, fully up to date in every way, include the following: three float- ing docks with lifting capacities of 20,000, 65,000 and 115,000 dwt; and a shipbuilding berth for the construction of vessels of up to 150,000 dwt.

The Althea is a bulk carrier of 43,300 dead- weight tons. She has an approximate overall length of 673 feet, extreme breadth of 89 feet, a trial speed of about 15.8 knots, and main engine developing 14,200 bhp. She is built for the bulk transportation of dry cargoes (ore, coal, grain, etc.) and incorporates all the de- sign features of a self-loading vessel. She will have air-conditioned accommodations for a crew of 43. The ship has been built in con- formity with the American Bureau of Shipping and under its supervision, and she flies the

Greek flag.

Eleusis 'Shipyards is represented in the Unit- ed States and Canada by Walter Thorsen Inc.,

One World Trade Center, New York, N.Y. 10048.

Ta Peng Line Names Chie

Asst. Operations Manager

John S.F. Chie has been appointed assistant operations manager for Ta Peng Line, accord- ing to O. Arnold Larsen, vice president, Trans- national Maritime, Inc., general agents for the line. Ta Peng maintains an independent op- eration between the Far East and the U.S.

Atlantic and Gulf.

Paclines To Carry Cargo

California To Hawaii

Using Tug And Superbarge

A superbarge, capable of carrying as much cargo as a World War II Liberty ship, is the mainstay of a new shipping service between the Port of Oakland, Calif., and Hawaii.

Paclines, operator of the service, employs a barge 336 feet long and 98 feet wide, towed by a 5,000-horsepower twin-screw tug in the run to and from the Islands.

The superbarge has a dry capacity of 324,000 cubic feet, in addition to cargo space on deck, for a total capacity of some 12,500 tons of freight.

The service will call at Oakland every 35 days.

A Paclines spokesman indicated that the service is designed to handle virtually all types of palletized and unitized cargo. A so-called "pass-pass" system is used in loading the float- ing giant, in which teams of forklifts hand-off cargo at the bullrail to a second team of fork- lifts aboard the barge, which stow the freight.

Because a ramp is used in loading, the service is also well-suited for shipping heavy machin- ery, the spokesman said.

In Oakland, the service is based at the port's

Ninth Avenue Terminal.

Paclines, which employs some 1,250 people worldwide and utilizes more than 100 barges, operates Pacific Inland Navigation, Alaska

Barge & Transport, B&R Tug and Barge, and

Seapac.

AUTOMATE! with the proven all-purpose

HOSE-McCANN

AUTOMATIC DIAL

TELEPHONE SYSTEMS interchangeable plug-in frays eliminate troubleshooting

PROVEN-Years of Trouble Free Service on World's Finest Ships

COMPLETE, FLEXIBLE FULLY AUTOMATIC DIAL TELEPHONE

SYSTEMS ENGINEERED FOR SHIPBOARD COMMUNICATIONS

Larger vessels, smaller crews and increased efficiency have created a need for a more flexible communications system to supplement sound powered telephones. Hose-McCann— pioneers in the introduction and development of sound powered telephones for marine use —provides the perfect answer with AUTOMATIC DIAL TELEPHONE SYSTEMS. Expandable systems available in 20, 40 and 100 line capacities. Larger systems available and engineered to meet your special requirements.

EXCLUSIVE HOSE-McCANN FEATURES

PLUG-IN TRAYS: Insure trouble-free operation and minimum maintenance. Identical and interchangeable, can be replaced instantly.

COMPONENTS: All electro-mechanical parts for the operation of the switchboard are located on the Plug-In Trays. All contacts self cleaning.

SWITCHBOARD CABINETS: Marine type cabinets are finished in gray baked hammertone enamel. Shock mounts minimize effects of shipboard vibrations. Switchboards are completely wired when shipped to provide quick and easy installation.

LINKAGE: 100% allows all stations to be used simultaneously.

CONFERENCE CALLING: Multiple conference facilities are standard equipment. More than one conference can be conducted, with the number of stations in any one conference being unlimited.

OPTIONAL FEATURES

PAGING: Permits voice paging from any telephone in the system.

EXECUTIVE-RIGHT-OF-WAY: Permits key personnel to override a busy signal.

HOSE McCANN

TELEPHONE CO., INC. 524 W. 23rd STREET • _ NEW YORK, N. Y. 10011 (Tel.) 989-7920 (Cable) CYBERNETIC NEWYORK

ORIGINATORS AND PIONEERS OF SOUND POWERED TELEPHONES FOR MARINE USE

Representatives in principal domestic and foreign seaports

Write For Complete Catalog D-661-MR

February 1, 1974 31

27

27

29

29