Page 8: of Maritime Reporter Magazine (September 1974)

Read this page in Pdf, Flash or Html5 edition of September 1974 Maritime Reporter Magazine

Todd Galveston Yard

Construction Backlog

Increases to $50 Million

The Galveston Division of Todcl

Shipyards Corporation has in re- cent months booked a substantial volume of diversified marine con- struction work—all scheduled for completion by the middle of 1975.

The total volume of this work is approximately $50 million.

A long-term contract with

Alamo Barge Lines calls for con- struction of two twin-screw 135- foot river pushboats and 12 liquid cargo barges. This contract is now well past the halfway mark.

The first set of four barges, in- tended for use in integrated 1,055- foot tows of four barges each, has already been delivered, as have two of the second set of barges.

The balance of the work, in vary- ing stages, is well along toward completion. This schedule origi- nally called for all of the units to be delivered before the middle of 1974. However, difficulties en- countered in obtaining the neces- sary steel precluded such deliver- ies, and the contract is now scheduled for completion later this year.

Todd has also been awarded, and will shortly sign, contracts covering the construction of four 96-foot tugboats for various com- panies, with deliveries set for 1975.

Already nearing completion—

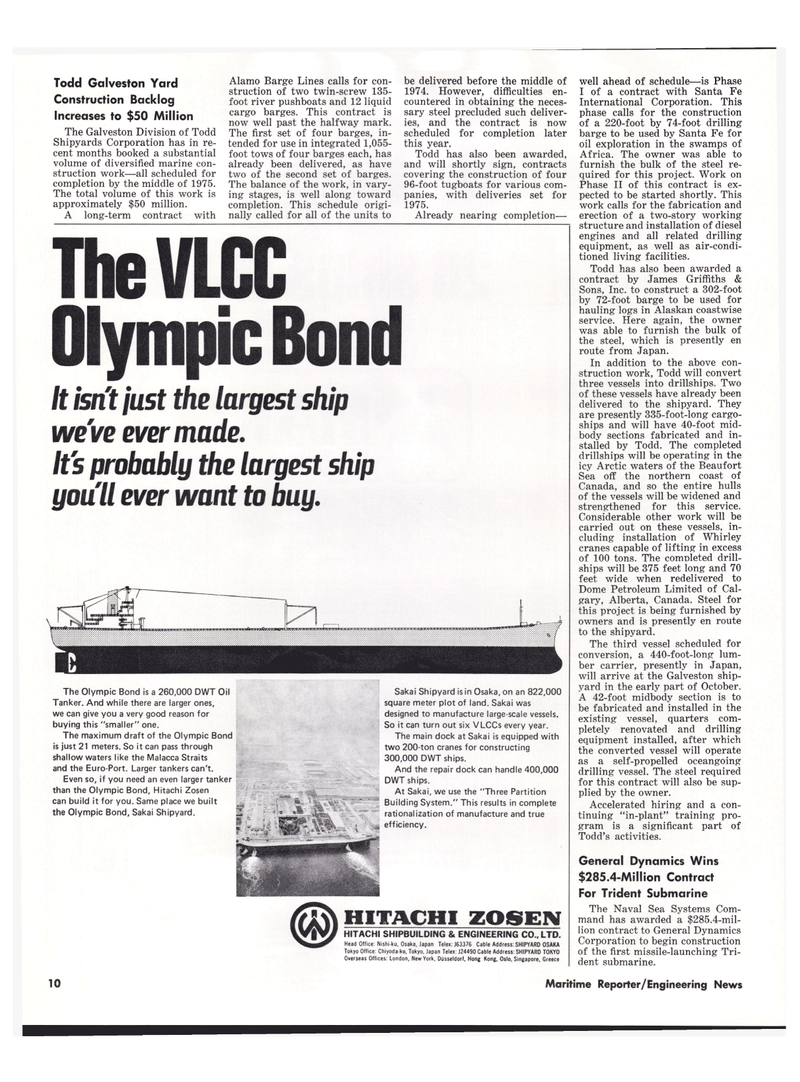

TheVLCC

Olympic Bond

It isn't just the largest ship we've ever made.

It's probably the largest ship you'll ever want to buy.

The Olympic Bond is a 260,000 DWT Oil

Tanker. And while there are larger ones, we can give you a very good reason for buying this "smaller" one.

The maximum draft of the Olympic Bond is just 21 meters. So it can pass through shallow waters like the Malacca Straits and the Euro-Port. Larger tankers can't.

Even so, if you need an even larger tanker than the Olympic Bond, Hitachi Zosen can build it for you. Same place we built the Olympic Bond, Sakai Shipyard.

Sakai Shipyard is in Osaka, on an 822,000 square meter plot of land. Sakai was designed to manufacture large-scale vessels.

So it can turn out six VLCCs every year.

The main dock at Sakai is equipped with two 200-ton cranes for constructing 300,000 DWT ships.

And the repair dock can handle 400,000

DWT ships.

At Sakai, we use the "Three Partition

Building System." This results in complete rationalization of manufacture and true efficiency.

HITACHI ZOSEN

HITACHI SHIPBUILDING & ENGINEERING CO., LTD.

Head Office: Nishj-ku. Osaka, Japan Telex: J63376 Cable Address: SHIPYARD OSAKA

Tokyo Office: Chiyodaku, Tokyo, Japan Telex: J24490 Cable Address: SHIPYARD TOKYO

Overseas Offices: London, New York, Diisseldorf, Hong Kong, Oslo. Singapore, Greece well ahead of schedule—is Phase

I of a contract with Santa Fe

International Corporation. This phase calls for the construction of a 220-foot by 74-foot drilling barge to be used by Santa Fe for oil exploration in the swamps of

Africa. The owner was able to furnish the bulk of the steel re- quired for this project. Work on

Phase II of this contract is ex- pected to be started shortly. This work calls for the fabrication and erection of a two-story working structure and installation of diesel engines and all related drilling equipment, as well as air-condi- tioned living facilities.

Todd has also been awarded a contract by James Griffiths &

Sons, Inc. to construct a 302-foot by 72-foot barge to be used for hauling logs in Alaskan coastwise service. Here again, the owner was able to furnish the bulk of the steel, which is presently en route from Japan.

In addition to the above con- struction work, Todd will convert three vessels into drillships. Two of these vessels have already been delivered to the shipyard. They are presently 335-foot-long cargo- ships and will have 40-foot mid- body sections fabricated and in- stalled by Todd. The completed drillships will be operating in the icy Arctic waters of the Beaufort

Sea off the northern coast of

Canada, and so the entire hulls of the vessels will be widened and strengthened for this service.

Considerable other work will be carried out on these vessels, in- cluding installation of Whirley cranes capable of lifting in excess of 100 tons. The comDleted drill- ships will be 375 feet long and 70 feet wide when redelivered to

Dome Petroleum Limited of Cal- gary, Alberta, Canada. Steel for this project is being furnished by owners and is presently en route to the shipyard.

The third vessel scheduled for conversion, a 440-foot-long lum- ber carrier, presently in Japan, will arrive at the Galveston ship- yard in the early part of October.

A 42-foot midbody section is to be fabricated and installed in the existing vessel, quarters com- pletely renovated and drilling equipment installed, after which the converted vessel will operate as a self-propelled oceangoing drilling vessel. The steel required for this contract will also be sup- plied by the owner.

Accelerated hiring and a con- tinuing "in-plant" training pro- gram is a significant part of

Todd's activities.

General Dynamics Wins $285.4-Million Contract

For Trident Submarine

The Naval Sea Systems Com- mand has awarded a $285.4-mil- lion contract to General Dynamics

Corporation to begin construction of the first missile-launching Tri- dent submarine. 60 Maritime Reporter/ Engineering News

7

7

9

9