Page 3rd Cover: of Maritime Reporter Magazine (July 1977)

Read this page in Pdf, Flash or Html5 edition of July 1977 Maritime Reporter Magazine

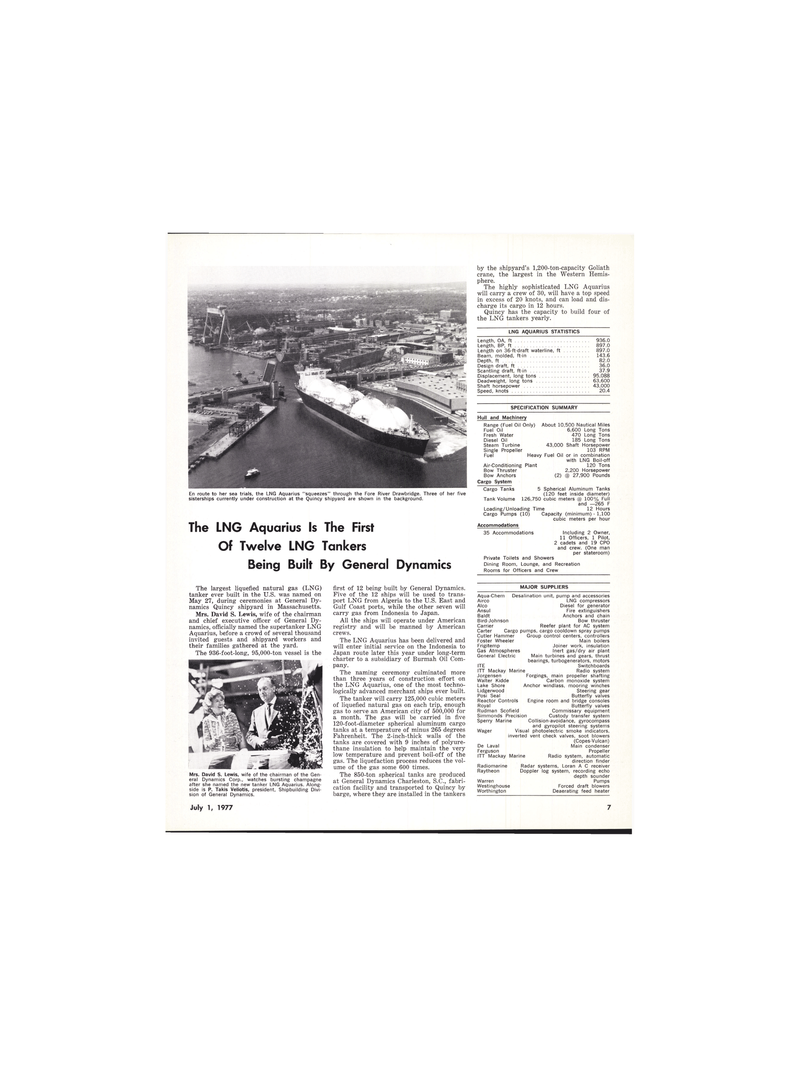

En route to her sea trials, the LNG Aquarius "squeezes" through the Fore River Drawbridge. Three of her five sisterships currently under construction at the Quincy shipyard are shown in the background.

The LNG Aquarius Is The First

Of Twelve LNG Tankers

Being Built By General Dynamics by the shipyard's 1,200-ton-capacity Goliath crane, the largest in the Western Hemis- phere.

The highly sophisticated LNG Aquarius will carry a crew of 30, will have a top speed in excess of 20 knots, and can load and dis- charge its cargo in 12 hours.

Quincy has the capacity to build four of the LNG tankers yearly.

LNG AQUARIUS STATISTICS

Length, OA, ft 936.0

Length, BP, ft 897.

Length on 36-ft-draft waterline, ft 897.0

Beam, molded, ft-in 143.6

Depth, ft 82.

Design draft, ft 36.0

Scantling draft, ft-in 37.9

Displacement, long tons 95,088

Deadweight, long tons 63,600

Shaft horsepower 43,00

Speed, knots 20.4

SPECIFICATION SUMMARY

Hull and Machinery

Range (Fuel Oil Only) About 10,500 Nautical Miles

Fuel Oil 6,600 Long Tons

Fresh Water 470 Long Tons

Diesel Oil 185 Long Tons

Steam Turbine 43,000 Shaft Horsepower

Single Propeller 103 RPM

Fuel Heavy Fuel Oil or in combination with LNG Boil-off

Air-Conditioning Plant 120 Tons

Bow Thruster 2,200 Horsepower

Bow Anchors (2) @ 27,900 Pounds

Cargo System

Cargo Tanks 5 Spherical Aluminum Tanks (120 feet inside diameter)

Tank Volume 126,750 cubic meters @ 100% Full and —265 F

Loading/Unloading Time 12 Hours

Cargo Pumps (10) Capacity (minimum) - 1,100 cubic meters per hour

Accommodations 35 Accommodations Including 2 Owner, 11 Officers, 1 Pilot, 2 cadets and 19 CPO and crew. (One man per stateroom)

Private Toilets and Showers

Dining Room, Lounge, and Recreation

Rooms for Officers and Crew

The largest liquefied natural gas (LNG) tanker ever built in the U.S. was named on

May 27, during ceremonies at General Dy- namics Quincy shipyard in Massachusetts.

Mrs. David S. Lewis, wife of the chairman and chief executive officer of General Dy- namics, officially named the supertanker LNG

Aquarius, before a crowd of several thousand invited guests and shipyard workers and their families gathered at the yard.

The 936-foot-long, 95,000-ton vessel is the

Mrs. David S. Lewis, wife of the chairman of the Gen- eral Dynamics Corp., watches bursting champagne after she named the new tanker LNG Aquarius. Along- side is P. Takis Veliotis, president, Shipbuilding Divi- sion of General Dynamics. first of 12 being built by General Dynamics.

Five of the 12 ships will be used to trans- port LNG from Algeria to the U.S. East and

Gulf Coast ports, while the other seven will carry gas from Indonesia to Japan.

All the ships will operate under American registry and will be manned by American crews.

The LNG Aquarius has been delivered and will enter initial service on the Indonesia to

Japan route later this year under long-term charter to a subsidiary of Burmah Oil Com- pany.

The naming ceremony culminated more than three years of construction effort on the LNG Aquarius, one of the most techno- logically advanced merchant ships ever built.

The tanker will carry 125,000 cubic meters of liquefied natural gas on each trip, enough gas to serve an American city of 500,000 for a month. The gas will be carried in five 120-foot-diameter spherical aluminum cargo tanks at a temperature of minus 265 degrees

Fahrenheit. The 2-inch-thick walls of the tanks are covered with 9 inches of polyure- thane insulation to help maintain the very low temperature and prevent boil-off of the gas. The liquefaction process reduces the vol- ume of the gas some 600 times.

The 850-ton spherical tanks are produced at General Dynamics Charleston, S.C., fabri- cation facility and transported to Quincy by barge, where they are installed in the tankers

MAJOR SUPPLIERS

Aqua-Chem Desalination unit, pump and accessories

Airco LNG compressors

Alco Diesel for generator

Ansul Fire extinguishers

Baldt Anchors and chain

Bird-Johnson Bow thruster

Carrier Reefer plant for AC system

Carter Cargo pumps, cargo cooldown spray pumps

Cutler Hammer Group control centers, controllers

Foster Wheeler Main boilers

Frigitemp Joiner work, insulation

Gas Atmospheres Inert gas/dry air plant

General Electric Main turbines and gears, thrust bearings, turbogenerators, motors

ITE Switchboard

ITT Mackay Marine Radio system

Jorgensen Forgings, main propeller shafting

Walter Kidde Carbon monoxide system

Lake Shore Anchor windlass, mooring winches

Lidgerwood Steering gear

Posi Seal Butterfly valves

Reactor Controls Engine room and bridge consoles

Royal Butterfly valves

Rudman Scofield Commissary equipment

Simmonds Precision Custody transfer system

Sperry Marine Collision-avoidance, gyrocompass and gyropilot steering systems

Wager Visual photoelectric smoke indicators, inverted vent check valves, soot blowers (Copes-Vulcan)

De Laval Main condenser

Ferguson Propelle

ITT Mackay Marine Radio system, automatic direction finder

Radiomarine Radar systems, Loran A C receiver

Raytheon Doppler log system, recording echo depth sounder

Warren Pumps

Westinghouse Forced draft blowers

Worthington Deaerating feed heater

July 1, 1977 7

4

4

4th Cover

4th Cover