Page 8: of Maritime Reporter Magazine (September 1977)

Read this page in Pdf, Flash or Html5 edition of September 1977 Maritime Reporter Magazine

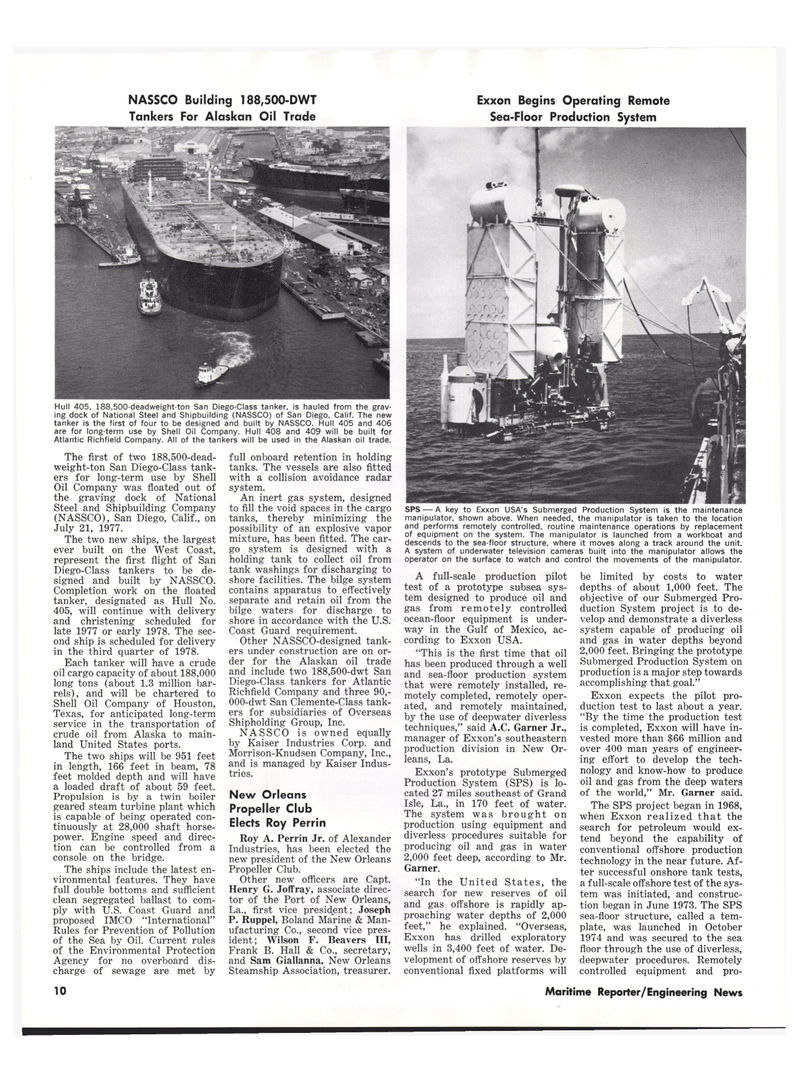

Hull 405, 188,500-deadweight-ton San Diego-Class tanker, is hauled from the grav- ing dock of National Steel and Shipbuilding (NASSCO) of San Diego, Calif. The new tanker is the first of four to be designed and built by NASSCO. Hull 405 and 406 are for long-term use by Shell Oil Company. Hull 408 and 409 will be built for

Atlantic Richfield Company. All of the tankers will be used in the Alaskan oil trade.

NASSCO Building 188,500-DWT

Tankers For Alaskan Oil Trade

Exxon Begins Operating Remote

Sea-Floor Production System

SPS —• A key to Exxon USA's Submerged Production System is the maintenance manipulator, shown above. When needed, the manipulator is taken to the location and performs remotely controlled, routine maintenance operations by replacement of equipment on the system. The manipulator is launched from a workboat and descends to the sea-floor structure, where it moves along a track around the unit.

A system of underwater television cameras built into the manipulator allows the operator on the surface to watch and control the movements of the manipulator.

The first of two 188,500-dead- weight-ton San Diego-Class tank- ers for long-term use by Shell

Oil Company was floated out of the graving dock of National

Steel and Shipbuilding Company (NASSCO), San Diego, Calif., on

July 21, 1977.

The two new ships, the largest ever built on the West Coast, represent the first flight of San

Diego-Class tankers to be de- signed and built by NASSCO.

Completion work on the floated tanker, designated as Hull No. 405, will continue with delivery and christening scheduled for late 1977 or early 1978. The sec- ond ship is scheduled for delivery in the third quarter of 1978.

Each tanker will have a crude oil cargo capacity of about 188,000 long tons (about 1.3 million bar- rels), and will be chartered to

Shell Oil Company of Houston,

Texas, for anticipated long-term service in the transportation of crude oil from Alaska to main- land United States ports.

The two ships will be 951 feet in length, 166 feet in beam, 78 feet molded depth and will have a loaded draft of about 59 feet.

Propulsion is by a twin boiler geared steam turbine plant which is capable of being operated con- tinuously at 28,000 shaft horse- power. Engine speed and direc- tion can be controlled from a console on the bridge.

The ships include the latest en- vironmental features. They have full double bottoms and sufficient clean segregated ballast to com- ply with U.S. Coast Guard and proposed IMCO "International"

Rules for Prevention of Pollution of the Sea by Oil. Current rules of the Environmental Protection

Agency for no overboard dis- charge of sewage are met by full onboard retention in holding tanks. The vessels are also fitted with a collision avoidance radar system.

An inert gas system, designed to fill the void spaces in the cargo tanks, thereby minimizing the possibility of an explosive vapor mixture, has been fitted. The car- go system is designed with a holding tank to collect oil from tank washings for discharging to shore facilities. The bilge system contains apparatus to effectively separate and retain oil from the bilge waters for discharge to shore in accordance with the U.S.

Coast Guard requirement.

Other NASSCO-designed tank- ers under construction are on or- der for the Alaskan oil trade and include two 188,500-dwt San

Diego-Class tankers for Atlantic

Richfield Company and three 90,- 000-dwt San Clemente-Class tank- ers for subsidiaries of Overseas

Shipholding Group, Inc.

NASSCO is owned equally by Kaiser Industries Corp. and

Morrison-Knudsen Company, Inc., and is managed by Kaiser Indus- tries.

New Orleans

Propeller Club

Elects Roy Perrin

Roy A. Perrin Jr. of Alexander

Industries, has been elected the new president of the New Orleans

Propeller Club.

Other new officers are Capt.

Henry G. Joffray, associate direc- tor of the Port of New Orleans,

La., first vice president; Joseph

P. Ruppel, Boland Marine & Man- ufacturing Co., second vice pres- ident; Wilson F. Beavers III,

Frank B. Hall & Co., secretary, and Sam Giallanna, New Orleans

Steamship Association, treasurer.

A full-scale production pilot test of a prototype subsea sys- tem designed to produce oil and gas from remotely controlled ocean-floor equipment is under- way in the Gulf of Mexico, ac- cording to Exxon USA. "This is the first time that oil has been produced through a well and sea-floor production system that were remotely installed, re- motely completed, remotely oper- ated, and remotely maintained, by the use of deepwater diverless techniques," said A.C. Garner Jr., manager of Exxon's southeastern production division in New Or- leans, La.

Exxon's prototype Submerged

Production System (SPS) is lo- cated 27 miles southeast of Grand

Isle, La., in 170 feet of water.

The system was brought on production using equipment and diverless procedures suitable for producing oil and gas in water 2,000 feet deep, according to Mr.

Garner. "In the United States, the search for new reserves of oil and gas offshore is rapidly ap- proaching water depths of 2,000 feet," he explained. "Overseas,

Exxon has drilled exploratory wells in 3,400 feet of water. De- velopment of offshore reserves by conventional fixed platforms will be limited by costs to water depths of about 1,000 feet. The objective of our Submerged Pro- duction System project is to de- velop and demonstrate a diverless system capable of producing oil and gas in water depths beyond 2,000 feet. Bringing the prototype

Submerged Production System on production is a major step towards accomplishing that goal."

Exxon expects the pilot pro- duction test to last about a year. "By the time the production test is completed, Exxon will have in- vested more than $66 million and over 400 man years of engineer- ing effort to develop the tech- nology and know-how to produce oil and gas from the deep waters of the world," Mr. Garner said.

The SPS project began in 1968, when Exxon realized that the search for petroleum would ex- tend beyond the capability of conventional offshore production technology in the near future. Af- ter successful onshore tank tests, a full-scale offshore test of the sys- tem was initiated, and construc- tion began in June 1973. The SPS sea-floor structure, called a tem- plate, was launched in October 1974 and was secured to the sea floor through the use of diverless, deepwater procedures. Remotely controlled equipment and pro- 10 Maritime Reporter/Engineering News

7

7

9

9