Page 13: of Maritime Reporter Magazine (November 1977)

Read this page in Pdf, Flash or Html5 edition of November 1977 Maritime Reporter Magazine

American Export Lines $43.1-Million Title XI

Approved By MarAd

The Maritime Administration (MarAd) has approved Title XI loan guarantees totaling $43.1 million to aid American Export

Lines, Inc. in financing two con- tainerships on order at the Bath (Maine) Iron Works Corporation shipyard, and refinancing two com- bination container-roll-on / roll-off vessels currently in service.

An $84.4-million contract for construction of the new container- ships, each 610 feet long and 16,300 deadweight tons, was an- nounced October 29, 1976.

Letter commitments to guaran- tee obligations under Title XI of the Merchant Marine Act of 1936, as amended, were authorized by the agency for the two new ves- sels when the construction con- tract was announced and for the two ro/ro vessels, the Red Jacket and the Young America, last

April 12.

Title XI financing has been ar- ranged for the two containerships in the amount of $17,450,000 each. The commitment for the

Red Jacket is $4,073,000, and for the Young America, $4,148,000.

Proceeds from bonds sold in re- financing the ro/ros will be used as equity in building the con- tainerships at Bath.

The Red Jacket and Young

America were built in 1969 and 1970, respectively, at Ingalls

Shipbuilding Division, Pascagoula,

Miss., and were acquired by AEL in 1970 from Moore-McCormack

Lines, Inc. They currently are op- erated in trade linking U.S. At- lantic ports with the Mediterra- nean—the same service for which the two containerships on order are intended.

The Title XI loan guarantee program is designed to attract private investment capital to the

U.S. maritime industry.

American Export Lines, Inc., a steamship company with head- quarters in New York, N.Y., re- ported in August increased reve- nues and net earnings equal to 83 cents a share for the first half of 1977.

Douglas Oehrlein Joins

Dravo SteelShip Corp.

Douglas L. Oehrlein

Douglas L. Oehrlein has been appointed marketing director for the Pine Bluff, Ark., shipyard of

Dravo SteelShip Corporation. The appointment was announced by

Edward D. Fry, vice president/ general manager of Dravo Steel-

Ship.

Mr. Oehrlein is a graduate of the University of Hawaii, where he obtained his B.S. degree in mechanical engineering with a specialty in marine structures.

He has held marketing positions with Tidewater, Inc., and most recently was marketing manager for Avondale Shipyards of New

Orleans, La.

Dravo SteelShip is a subsidiary of Dravo Corporation, Pittsburgh,

Pa., an international engineer con- structor with more than 85 years' experience in the marine indus- try. Dravo SteelShip, located at

Mile 73 on the Arkansas River, specializes in the construction of both steel and aluminum com- mercial vessels up to 200 feet in length.

For more information on Dravo

SteelShip's tugs, pushboats, sup- ply boats, or other work vessels, write Dravo SteelShip Corpora- tion, Route 4, Box 167, Pine Bluff,

Ark. 71602. Gulf Coast customers can telephone Mr. Oehrlein at 504/722-6677 for quick response.

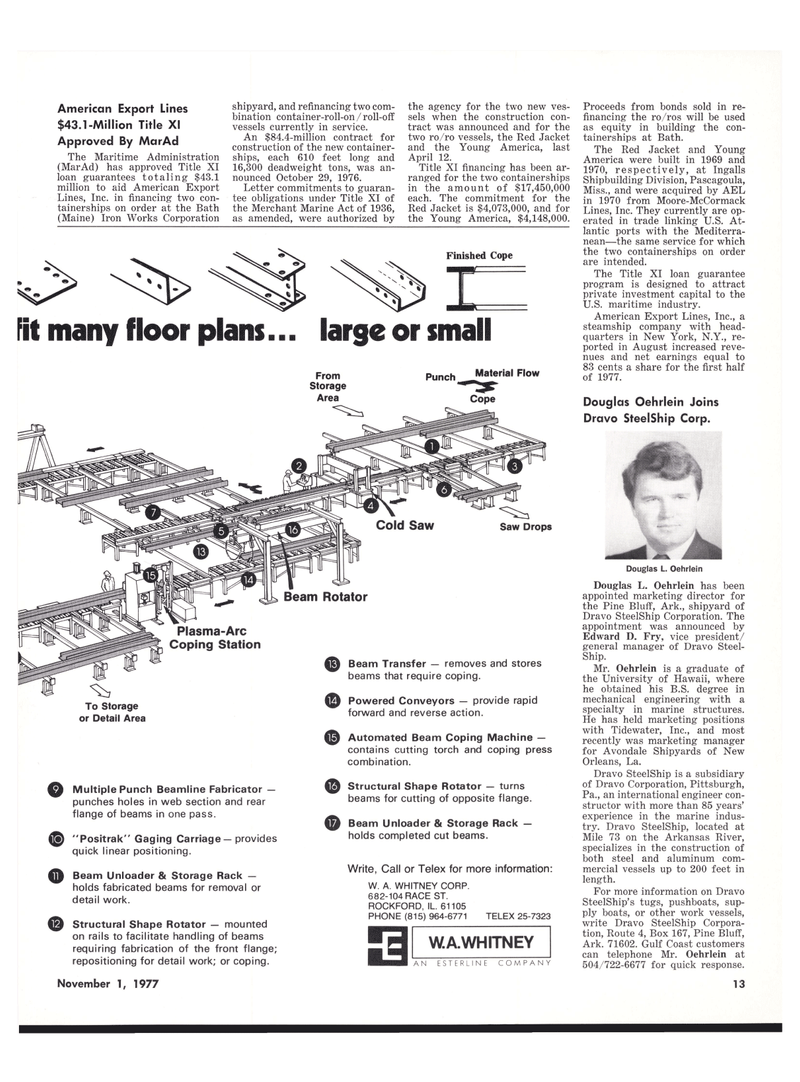

Finished Cope

I many floor plans... large or small

Multiple Punch Beamline Fabricator — punches holes in web section and rear flange of beams in one pass. "Positrak" Gaging Carriage — provides quick linear positioning. ^^ Beam Unloader & Storage Rack — holds fabricated beams for removal or detail work. ^^ Structural Shape Rotator — mounted on rails to facilitate handling of beams requiring fabrication of the front flange; repositioning for detail work; or coping. ^^ Automated Beam Coping Machine — contains cutting torch and coping press combination. ^^ Structural Shape Rotator — turns beams for cutting of opposite flange. ^^ Beam Unloader & Storage Rack — holds completed cut beams.

Write, Call or Telex for more information:

W. A. WHITNEY CORP. 682-104 RACE ST.

ROCKFORD, IL. 61105

PHONE (815) 964-6771 TELEX 25-7323 s W.A. WHITNEY AN ESTERLINE COMPANY

From

Storage

Area

Punch Material Flow

Cold Saw Saw Drops

Beam Rotator ^^ Beam Transfer — removes and stores beams that require coping. ^^ Powered Conveyors — provide rapid forward and reverse action.

Plasma-Arc

Coping Station

To Storage or Detail Area

November 1, 1977 13

12

12

14

14