Page 3: of Maritime Reporter Magazine (November 15, 1977)

Read this page in Pdf, Flash or Html5 edition of November 15, 1977 Maritime Reporter Magazine

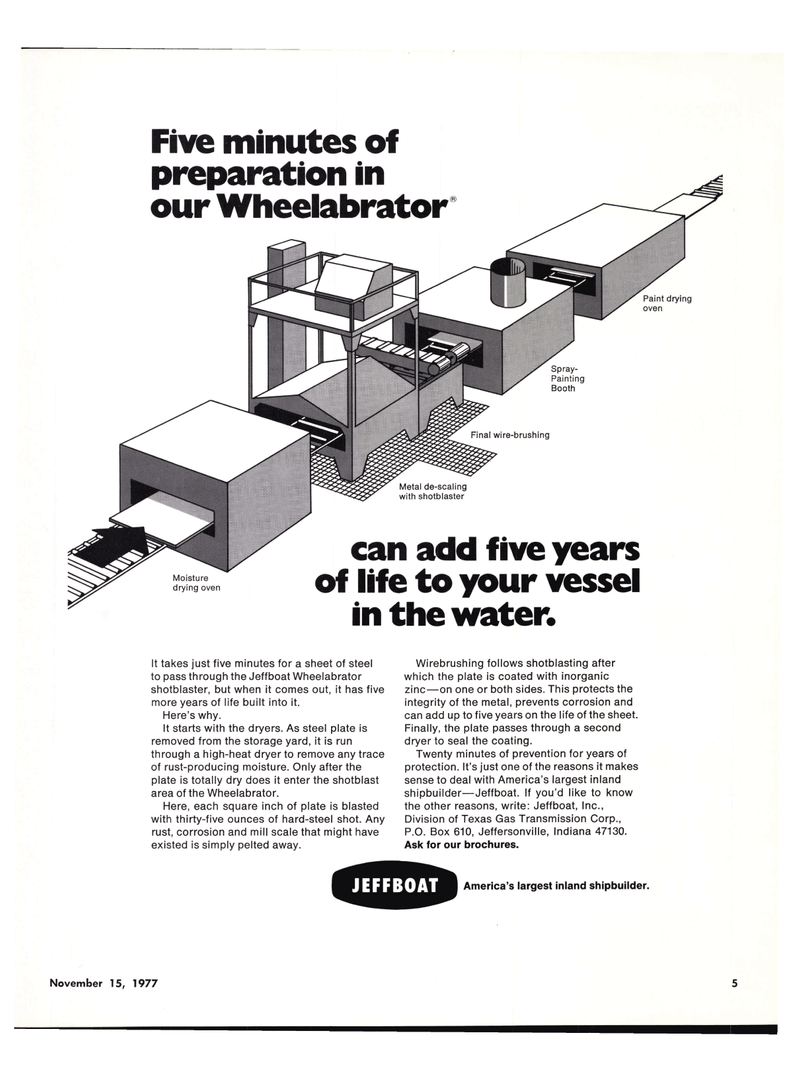

Five minutes of preparation in our Wheelabrator

Paint drying oven

Final wire-brushing

Metal de-scaling with shotblaster

Moisture drying oven can add five years of life to your vessel in the water.

It takes just five minutes for a sheet of steel to pass through the Jeffboat Wheelabrator shotblaster, but when it comes out, it has five more years of life built into it.

Here's why.

It starts with the dryers. As steel plate is removed from the storage yard, it is run through a high-heat dryer to remove any trace of rust-producing moisture. Only after the plate is totally dry does it enter the shotblast area of the Wheelabrator.

Here, each square inch of plate is blasted with thirty-five ounces of hard-steel shot. Any rust, corrosion and mill scale that might have existed is simply pelted away.

Wirebrushing follows shotblasting after which the plate is coated with inorganic zinc—on one or both sides. This protects the integrity of the metal, prevents corrosion and can add up to five years on the life of the sheet.

Finally, the plate passes through a second dryer to seal the coating.

Twenty minutes of prevention for years of protection. It's just one of the reasons it makes sense to deal with America's largest inland shipbuilder—Jeffboat. If you'd like to know the other reasons, write: Jeffboat, Inc.,

Division of Texas Gas Transmission Corp.,

P.O. Box 610, Jeffersonville, Indiana 47130.

Ask for our brochures.

JEFFBOAT America's largest inland shipbuilder.

November 15, 1977 5

2

2

4

4