Page 33: of Maritime Reporter Magazine (January 1978)

Read this page in Pdf, Flash or Html5 edition of January 1978 Maritime Reporter Magazine

Intermarine Electronics — Regional Dealer Seminar Bay-Houston Expands Harbor Towing Fleet

Intermarine Electronics recently held a meeting at its headquarters at St. James, N.Y., for its dealers from New York, Connecticut and

New Jersey. The occasion marked the introduction of the company's new marine radar, the "Intermarine 705," which was demonstrated in operation at nearby Stony Brook Harbor. The new radar is a com- pact two-unit equipment introduced for use by commercial fishermen and yachtsmen who want radar performance out to 32 miles without the expense or complexity of other contemporary sets. Deliveries com- menced in October, and the radar is backed-up by a nationwide net- work of sales and service dealers. Pictured above are attendees at the St. James meeting. Top row, left to right: Ludwig K. Rubinsky,

Electronautical Equipment Inc.; George Mihailidis, Connecticut Ma- rine Electronics Inc.; Philip D'Ambra, Intermarine Electronics Inc.;

Carsten Peters, Arnessen Corp.; John P. Glynn, Intermarine Elec- tronics Inc.; James Chapman, Griffith Marine Navigation, Inc.; Jack

Wall, Electro-Nav, Inc.; Nick Edmondson, NPE & Associates, Inc., and Frank J. Cizin, Maritime Communications Inc. Bottom row, left to right: Peter Calimano, South Shore Marine Radio, Inc.; John T.

Koleda, South Shore Marine Radio, Inc.; Keith Dickenson, Inter- marine Electronics Inc.; Werner Brack, Intermarine Electronics, Inc.;

Gerald Gutman, Nav-Com, Inc.; Murray Cohen, Rad-Com, Inc., and

Edwin Foy, Seatronics, Inc.

World's Largest Rotary Screw Pump

Passes Performance Tests At DeLaval

Testing of the world's largest rotary screw pump at the IMO® Pump Division,

DeLaval Turbine Inc., Trenton, N.J. Complete "train" includes DeLaval pump (left), fluid coupling (center), and electric motor (right). "Full train testing" of an inte- grated Cargo Pumping System engineered by the IMO Pump Di- vision, DeLaval Turbine Inc. has just been completed at the com- pany's test facilities in Trenton,

N.J. The "train" includes the largest rotary screw pump ever produced, powered by a 1,000- horsepower electric motor through a variable speed fluid coupling.

Thorough testing by DeLaval was necessary to demonstrate the pumping system's capability to unload high vapor pressure, high viscosity crude from an offshore storage vessel.

Test facility instrumentation enabled a thorough analysis of pump performance. In addition to a full spectrum vibration analy- sis, a torque meter was utilized to measure input power. The pump was operated over the full speed range of 300 to 1,150 rpm at flows up to 5,500 gallons per minute, up to the maximum pres- sure of 165 pounds per square inch. Data taken indicated a suc- tion lift capability of 27 inches of mercury.

DeLaval Turbine Inc., a Trans- america Company, has 15 oper- ating divisions at 18 manufactur- ing locations worldwide. The com- pany makes a line of industrial products including compressors, condensers, connectors, controls, diesel engines, fasteners, filters, forgings, gearing, pumps, sensors, turbines and valves.

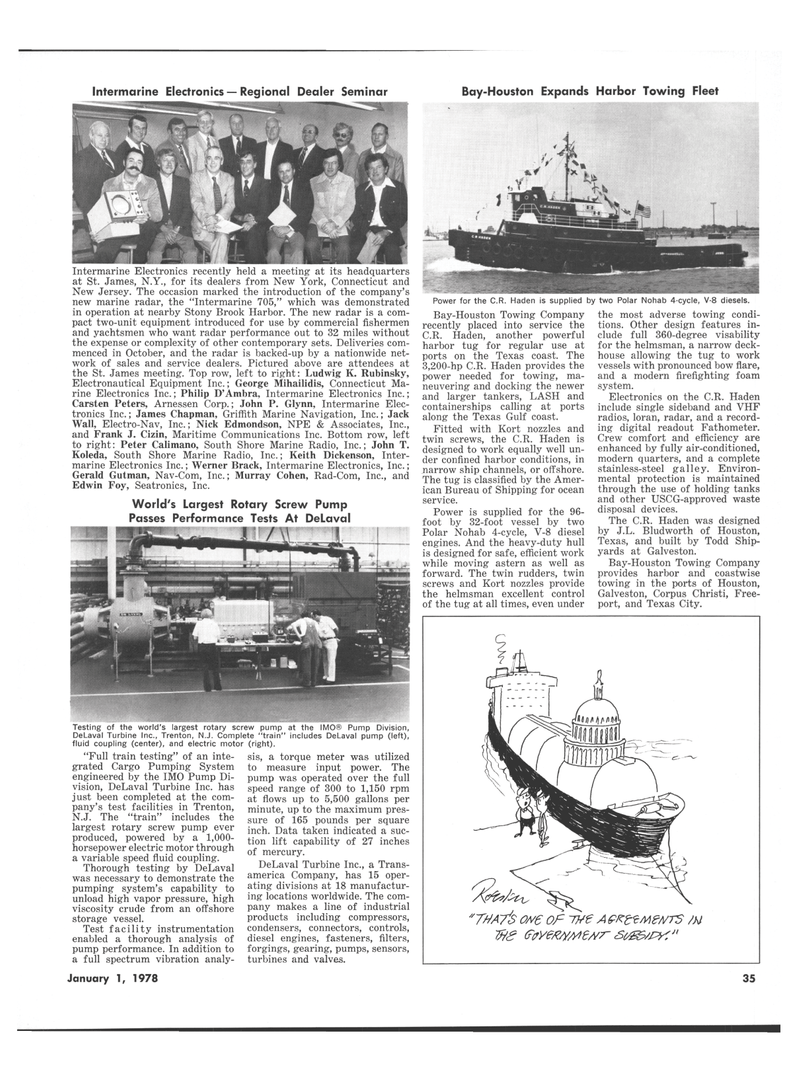

Power for the C.R. Haden is supplied by two Polar Nohab 4-cycle, V-8 diesels.

Bay-Houston Towing Company recently placed into service the

C.R. Haden, another powerful harbor tug for regular use at ports on the Texas coast. The 3,200-hp C.R. Haden provides the power needed for towing, ma- neuvering and docking the newer and larger tankers, LASH and containerships calling at ports along the Texas Gulf coast.

Fitted with Kort nozzles and twin screws, the C.R. Haden is designed to work equally well un- der confined harbor conditions, in narrow ship channels, or offshore.

The tug is classified by the Amer- ican Bureau of Shipping for ocean service.

Power is supplied for the 96- foot by 32-foot vessel by two

Polar Nohab 4-cycle, V-8 diesel engines. And the heavy-duty hull is designed for safe, efficient work while moving astern as well as forward. The twin rudders, twin screws and Kort nozzles provide the helmsman excellent control of the tug at all times, even under the most adverse towing condi- tions. Other design features in- clude full 360-degree visability for the helmsman, a narrow deck- house allowing the tug to work vessels with pronounced bow flare, and a modern firefighting foam system.

Electronics on the C.R. Haden include single sideband and VHF radios, loran, radar, and a record- ing digital readout Fathometer.

Crew comfort and efficiency are enhanced by fully air-conditioned, modern quarters, and a complete stainless-steel galley. Environ- mental protection is maintained through the use of holding tanks and other USCG-approved waste disposal devices.

The C.R. Haden was designed by J.L. Bludworth of Houston,

Texas, and built by Todd Ship- yards at Galveston.

Bay-Houston Towing Company provides harbor and coastwise towing in the ports of Houston,

Galveston, Corpus Christi, Free-

port, and Texas City.

'TMA7i> owe OF Th January 1, 1978 35

32

32

34

34