Page 14: of Maritime Reporter Magazine (July 15, 1978)

Read this page in Pdf, Flash or Html5 edition of July 15, 1978 Maritime Reporter Magazine

Approximately 90 members and guests attended a joint meeting of the Pacific Northwest Section of The Society of Naval Archi- tects and Marine Engineers and the American Society of Naval

Engineers held at the Commis- sioned Officers' Mess, Puget

Sound Naval Shipyard, Bremer- ton, Wash., June 8, 1978.

Prior to the meeting, a tour of the Naval Shipyard was experi- enced by the U.S. citizens, while non-U.S. citizens enjoyed a visit to the battleship USS Missouri, of World War II fame.

Capt. J. K. Nunneley, Com- mander of the shipyard, welcomed members and guests of both So- cieties to Bremerton. M.L. Ing- wersen, executive vice president,

Lockheed Shipbuilding, and chair- man of ASNE, also welcomed all

SNAME members and guests, and trusted that this would be the forerunner of many meetings to come.

After dinner, a technical paper titled "Use of Air Bearings for

Pierside Loading Ramps" was presented by Marcellus W. Cave, mechanical engineer, Puget Sound

Naval Shipyard.

In his opening remarks, the au- thor stated that the purpose of this paper was the justification of the selection of air bearings to support a vehicle loading/offload- ing ramp for waterborne ships, especially an aircraft carrier, which required unloading 700 to 1,000 personal vehicles of the crew necessary for their moving into

Bremerton housing to allow the overhaul work to begin as soon as possible. Using the existing method, consisting of a ramp worked by a small crew and crane, unloading time was two days, therefore improvement was mandatory. This was obtained after an analysis of the perform- ance of the following types of bearings: (1) Air or water bear- ings; (2) Rubber tread casters; (3) Vibrathane tread casters, and (4) Spherical bearings.

Air bearings were selected on the basis that: (a) They offer practically no opposition to move- ment in any horizontal direction; (b) They impose much smaller forces on the aircraft carrier than the others; (c) They are fairly inexpensive to purchase ($1,000 to $1,500 for a bearing rated at 20,000 pounds), and (d) They are inexpensive to operate (about $.025 per hour for the above bearing).

In conclusion, the author stated that after the existing steel ramp was modified to accept air bear- ings, the unloading time was re- duced from two days to two hours, with further timesavings expected as more experience was gained.

The original goal had been at- tained.

Copies of the paper can be ob- tained from the Section Librar- ian, C.S. Bracken, P.O. Box 24382,

Seattle, Wash. 98124.

Tank Ship Fleet

Analysis Released

According to the detailed tank- er report just published by Sun

Shipbuilding and Dry Dock Com- pany, the world tanker fleet con- tinued to grow in 1976 with a 9.6 percent increase in capacity over the previous year. This annual study, "The Analysis of World

Tank Ship Fleet," shows that this increase, the smallest in the last nine years, raised the world fleet to a record 5,140 tank ships with a 382.5-million-deadweight-ton (dwt) capacity by the end of 1976.

The tankers operating under the Liberian flag maintained their world leadership with 112.9 mil- lion dwt, followed by Japan,

United Kingdom, Norway and

Greece. Among the leading na- tions, the United States-flag tank- er fleet was in the eighth position.

With the exception of United

Kingdom, all leading nations showed increases under their flag in spite of the accelerated retire- ment of older tankers during the last two years. Again, Liberia showed the largest increase, with 11 million deadweight tons, fol- lowed by Japan, with an addition of almost 3 million tons to her flag fleet. The continued scrap- page of the older ships decreased the average age of the world fleet to six years and four months by the end of 1976. Sharp increases in fuel costs since 1973 justified the building of larger and slower tankers. By the end of 1976, re- cent new shipbuilding had in- creased the average tanker size to 74,400 dwt, and decreased the speed to 15.7 knots from 15.8 knots of the early 1970s.

As a result of the continued large tanker layups and pessimis- tic tanker demand forecasts, con- struction contracts showed an even sharper decline in 1976 than they did the previous year. Tank-

Halter Marine Services, Inc.,

New Orleans, La., has delivered the San Jose Island and the

Breton Island, two identical sup- ply vessels, to their owner, Ar- thur Levy Enterprises, Inc., New

Orleans.

Each vessel has an overall length of 185 feet, a 40-foot beam, a 14-foot draft, and a normal op- erating draft of 12 feet. Their normal displacement is 1,590 long tons.

Both are powered by two EMD 12-645-C diesel engines that pro- duce 1,500 horsepower each at 900 revolutions per minute. Re- verse/reduction gearing is Falk 0830 MR with a ratio of 2.968:1.

The boats are also equipped with 90-inch-diameter four-bladed stainless-steel propellers and elec- trohydraulic steering gear from

Steering Systems, Inc.

Deck machinery includes an

HBL anchor windlass and HBL capstans.

Each contains a Smatco Bulk

Mud System with a total capacity of 6,000 cubic feet of dry bulk mud. ers under construction contracts or on order totaled 52 million dwt, the lowest tanker orderbook since 1968. More than 23 percent of the newbuilding was contracted by the largest shipbuilder of the last decade, Japan, followed by United

States, Sweden, Spain and United

Kingdom.

An added feature of the cur- rent edition of the Sun Shipbuild- ing publication is a discussion of the basic aspects of modern tank- ships, their functional design and typical cargo characteristics. It shows in simple terms the results of the tanker evolution that fol- lowed the exploding growth of the trade of liquid fuels. "The Analysis of World Tank

Ship Fleet, December 31, 1976," is the 35th edition of the annual

Sun Shipbuilding and Dry Dock publication. It is available for $15 per copy from Tanker Fleet Anal- ysis, Sun Shipbuilding and Dry

Dock Company, P. O. Box 86,

Chester, Pa. 19013.

Auxiliary equipment includes

Delco 98KW main generators driven by Detroit 8V71 diesel en- gines. Also included is a 29-point engine monitoring alarm system, 10 tons of central air-conditioning and heating, and Quincy air com- pressors.

Navigation and communications equipment consists of a Raytheon

DE-731 depth recorder, two

Raytheon 1220/6X radars and a

Wesmar DDS600 digital depth sounder with remote display in the captain's cabin. Also included is an RF 448 VHF radio, an RF 220 SSB radio, a DC700 digital compass, a Sperry MK 37 gyro- compass and a Sperry 8T mag- netic compass and autopilot.

The San Jose Island and the

Breton Island are each equipped with a Bird-Johnson 300-horse- power bowthruster for improved maneuverability during loading and offloading.

Halter Marine Services owns and operates 10 shipyards in the

Southeastern United States and is the world's largest builder of offshore supply vessels.

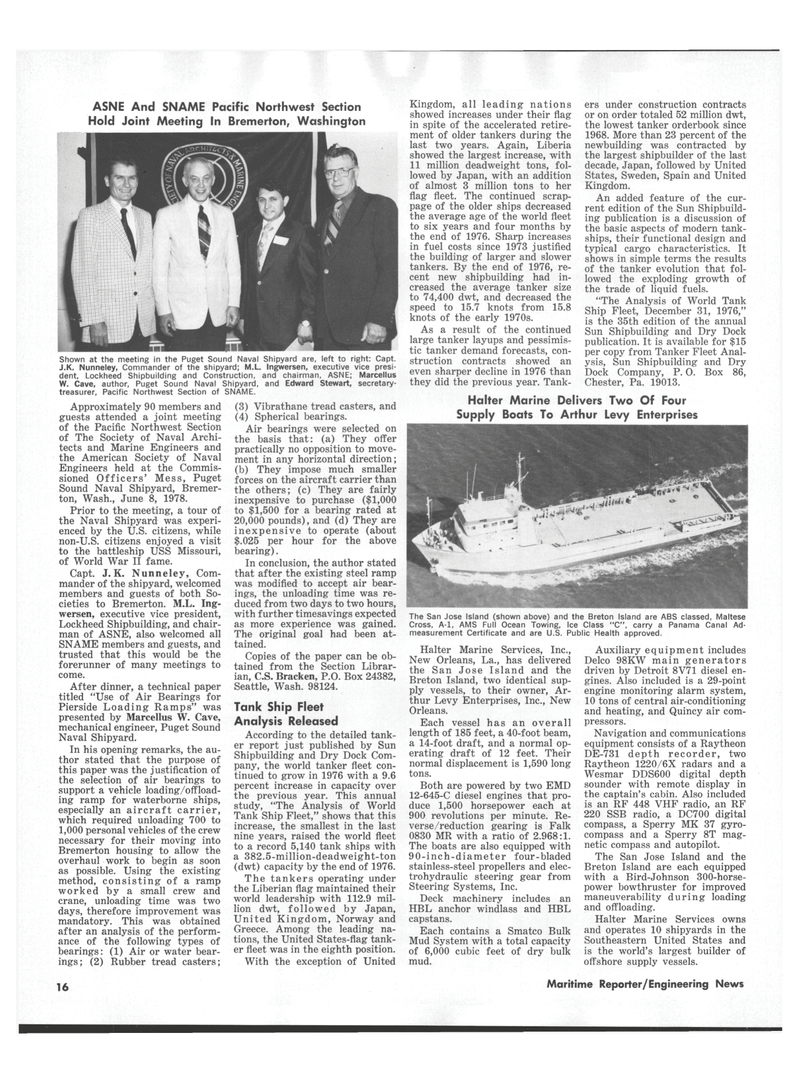

ASNE And SNAME Pacific Northwest Section

Hold Joint Meeting In Bremerton, Washington

Shown at the meeting in the Puget Sound Naval Shipyard are, left to right: Capt.

J.K. Nunneley, Commander of the shipyard; M.L. Ingwersen, executive vice presi- dent, Lockheed Shipbuilding and Construction, and chairman, ASNE; Marcellus

W. Cave, author, Puget Sound Naval Shipyard, and Edward Stewart, secretary- treasurer, Pacific Northwest Section of SNAME. Halter Marine Delivers Two Of Four

Supply Boats To Arthur Levy Enterprises

The San Jose Island (shown above) and the Breton Island are ABS classed, Maltese

Cross, A-l, AMS Full Ocean Towing, Ice Class "C", carry a Panama Canal Ad- measurement Certificate and are U.S. Public Health approved. 16 Maritime Reporter/Engineering News

13

13

15

15