Page 10: of Maritime Reporter Magazine (September 1978)

Read this page in Pdf, Flash or Html5 edition of September 1978 Maritime Reporter Magazine

# Why every in the world

And why

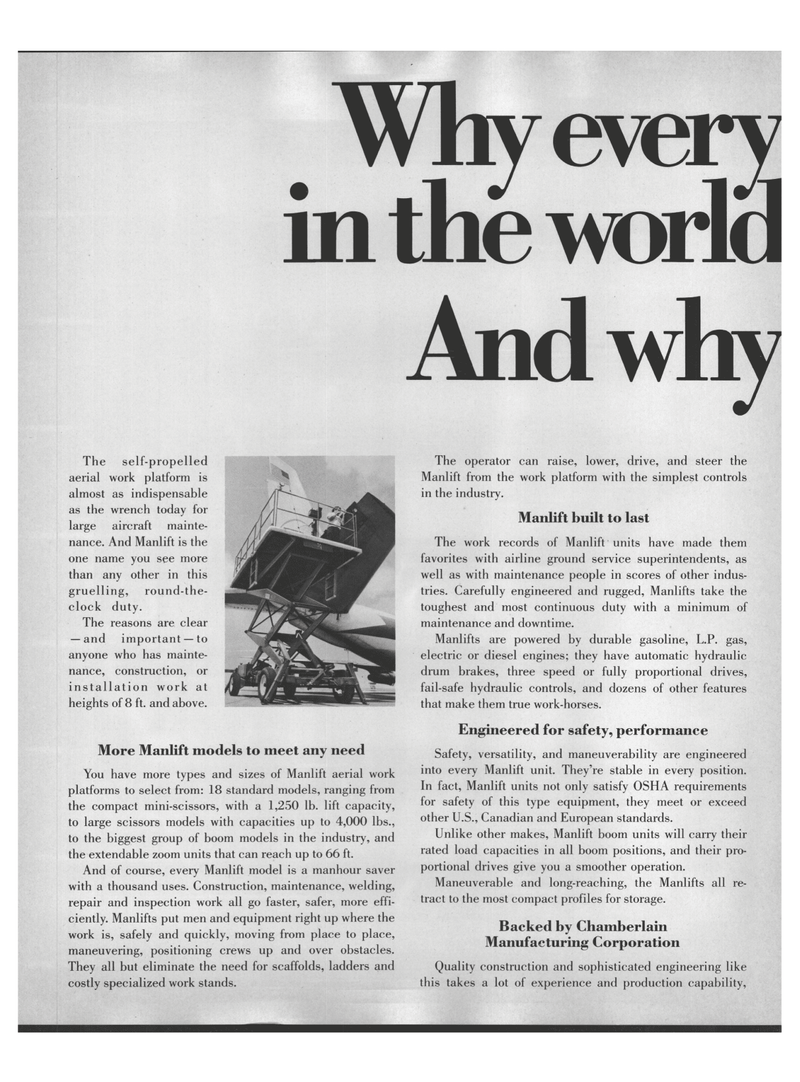

The self-propelled aerial work platform is almost as indispensable as the wrench today for large aircraft mainte- nance. And Manlift is the one name you see more than any other in this gruelling, round-the- clock duty.

The reasons are clear — and important —to anyone who has mainte- nance, construction, or installation work at heights of 8 ft. and above.

More Manlift models to meet any need

You have more types and sizes of Manlift aerial work platforms to select from: 18 standard models, ranging from the compact mini-scissors, with a 1,250 lb. lift capacity, to large scissors models with capacities up to 4,000 lbs., to the biggest group of boom models in the industry, and the extendable zoom units that can reach up to 66 ft.

And of course, every Manlift model is a manhour saver with a thousand uses. Construction, maintenance, welding, repair and inspection work all go faster, safer, more effi- ciently. Manlifts put men and equipment right up where the work is, safely and quickly, moving from place to place, maneuvering, positioning crews up and over obstacles.

They all but eliminate the need for scaffolds, ladders and costly specialized work stands.

The operator can raise, lower, drive, and steer the

Manlift from the work platform with the simplest controls in the industry.

Manlift built to last

The work records of Manlift units have made them favorites with airline ground service superintendents, as well as with maintenance people in scores of other indus- tries. Carefully engineered and rugged, Manlifts take the toughest and most continuous duty with a minimum of maintenance and downtime.

Manlifts are powered by durable gasoline, L.P. gas, electric or diesel engines; they have automatic hydraulic drum brakes, three speed or fully proportional drives, fail-safe hydraulic controls, and dozens of other features that make them true work-horses.

Engineered for safety, performance

Safety, versatility, and maneuverability are engineered into every Manlift unit. They're stable in every position.

In fact, Manlift units not only satisfy OSHA requirements for safety of this type equipment, they meet or exceed other U.S., Canadian and European standards.

Unlike other makes, Manlift boom units will carry their rated load capacities in all boom positions, and their pro- portional drives give you a smoother operation.

Maneuverable and long-reaching, the Manlifts all re- tract to the most compact profiles for storage.

Backed by Chamberlain

Manufacturing Corporation

Quality construction and sophisticated engineering like this takes a lot of experience and production capability,

9

9

11

11