Page 5: of Maritime Reporter Magazine (September 1978)

Read this page in Pdf, Flash or Html5 edition of September 1978 Maritime Reporter Magazine

Galley Equipment

Range: Toastmaster Model

G20M1RA.

Freezer: 45-cubic-foot Jordan reach-in unit.

Refrigerators: 14-cubic-f oot

Westinghouse night box and 45- cubic-foot Jordan reach-in box.

Deck Machinery

Capstans: One Schoellhorn-

Albrecht Co. type 21063, two- speed, 10 hp.

Winches: Two Beebe, Model 62, 5-hp electric.

Boat hoists: One iy2-ton elec- tric units; electric remote control, 50 tons.

Navigation & Communication

Equipment

Radar: Sperry MK16.

Digital Depth Indicator: Ray- theon DE-760.

Intercom: TOA/Moakler.

Sound-powered telephone:

Hose-McCann.

Searchlight: Carlisle & Finch, two Xenon.

Air horn: Kahlenberg, Model

Q-4.

Tugmonitor: National Marine

Series W, Model 01038.

Closed-circuit TV: Sanyo-Model

VM 4092 monitors, 4 Sanyo Model

VC1600x cameras.

Swing-O-Meter: Shannon Model 2B.

Radio: Modar D80SCA SSB, 1-Modar Triton 55/75 VHF, 1-intech Vio8BB VHF.

Rhine-Schelde-Verolme

And IHC Offshore Yard

Effect Shipbuilding Merger

A reorganization of the Dutch shipbuilding industries has re- sulted in the merger of IHC

Gusto, the offshore yard of IHC

Holland, into the Rhine-Schelde-

Verolme Group (RSV) .This merg- er became effective July 15, 1978.

The production facilities of

Gusto will be shut down and its labor force will be transferred to the RSV yards, principally the large Verolme Dok-en Scheeps- bouw at Rozenburg, near Rotter- dam.

The IHC Gusto design and en- gineering departments (approxi- mately 130 men) has been merged into a new engineering company under the name of RSV Gusto

Engineering. IHC Gusto Engi- neering has a well-established rec- ord in the offshore industry, hav- ing designed such advanced sys- tems as the Pelican type dynamic positioned drillships, large off- shore cranes such as Thor, and the 3,000-ton crane for Heerema's semisubmersible crane barge

Balder, jackups such as the Ma- ersk Explorer, pipelaying barges including the Viking Piper, and offshore storage systems such as the Shell Esso Brent Spar. IHC

Gusto received the 1978 Offshore

Technology Conference Distin- guished Achievement Award, which in a large part was due to the accomplishments of the Gusto design and engineering depart- ments.

The new company, RSV Gusto

Engineering will, in addition to providing engineering services, continue to offer the famous

Gusto products to the offshore industry. In view of the policy of many governments to stimulate construction in domestic ship- yards, RSV Gusto Engineering has been organized to provide complete project responsibility for engineering and construction of offshore systems at any ship- yard in the world. This philosophy had already been successfully im- plemented in the construction of a series of 2,000-ton and 3,000-ton offshore cranes for the Nether- lands Offshore Company and

Heerema Marine Contractors.

These cranes were built by Sumi- tomo Heavy Industries in Japan under the project management, engineering, and quality control provided by Gusto. J.D. Bax and

W.A.G. de Vries have been ap- pointed as managing directors of

RSV Gusto Engineering.

INVOICE

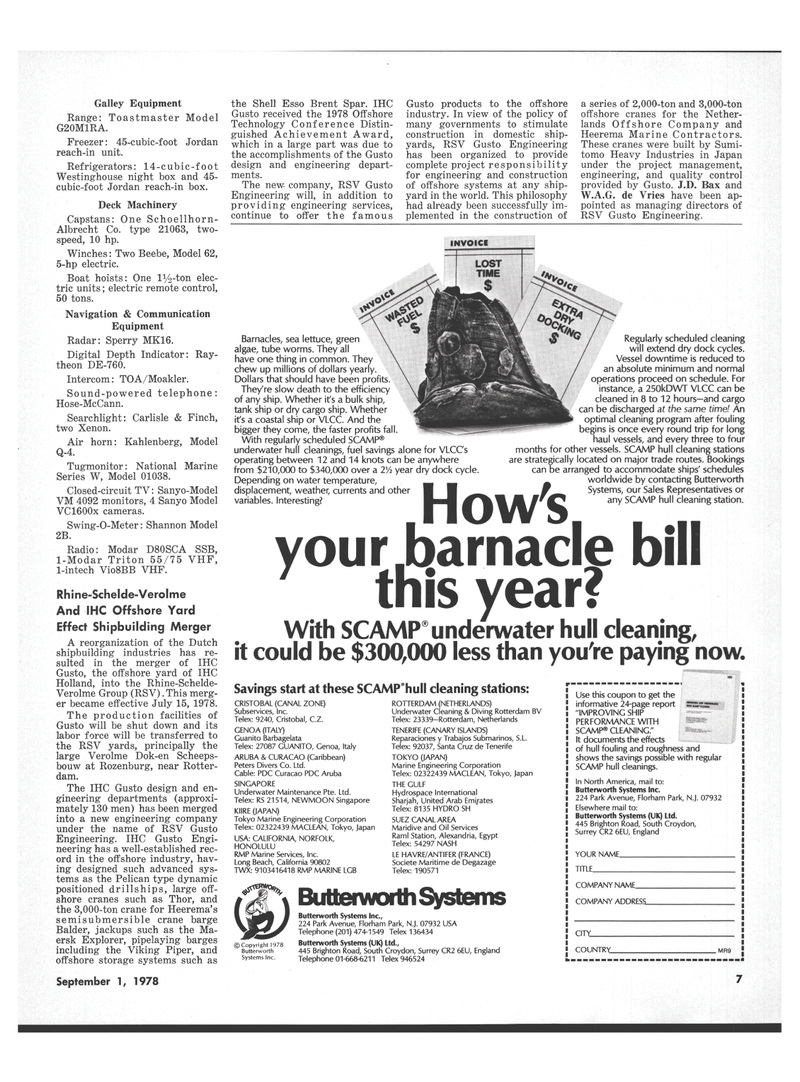

Barnacles, sea lettuce, green algae, tube worms. They all have one thing in common. They chew up millions of dollars yearly.

Dollars that should have been profits.

They're slow death to the efficiency of any ship. Whether ifs a bulk ship, tank ship or dry cargo ship. Whether it's a coastal ship or VLCC. And the bigger they come, the faster profits fall.

With regularly scheduled SCAMP® underwater hull cleanings, fuel savings alone for VLCC's operating between 12 and 14 knots can be anywhere from $210,000 to $340,000 over a 2Vi year dry dock cycle.

Depending on water temperature, displacement, weather, currents and other variables. Interesting? , How's, your .barnacle this vear?

Regularly scheduled cleaning will extend dry dock cycles.

Vessel downtime is reduced to an absolute minimum and normal operations proceed on schedule. For instance, a 250kDWT VLCC can be cleaned in 8 to 12 hours—and cargo can be discharged at the same time! An optimal cleaning program after fouling begins is once every round trip for long haul vessels, and every three to four months for other vessels. SCAMP hull cleaning stations are strategically located on major trade routes. Bookings be arranged to accommodate ships' schedules worldwide by contacting Butterworth

Systems, our Sales Representatives or any SCAMP hull cleaning station. can I bill

With SCAMP® underwater hull cleaning, it could be $300,000 less than you're paying now.

Savings start at these SCAMP'hull cleaning stations:

CRISTOBAL (CANAL ZONE)

Subservices, Inc.

Telex: 9240, Cristobal, C.Z.

GENOA (ITALY)

Guanito Barbagelata

Telex: 27087 GUANITO, Genoa, Italy

ARUBA & CURACAO (Caribbean)

Peters Divers Co. Ltd.

Cable: PDC Curacao PDC Aruba

SINGAPORE

Underwater Maintenance Pte. Ltd.

Telex: RS 21514, NEWMOON Singapore

KIIRE (JAPAN)

Tokyo Marine Engineering Corporation

Telex: 02322439 MACLEAN, Tokyo, Japan

USA: CALIFORNIA, NORFOLK,

HONOLULU

RMP Marine Services, Inc.

Long Beach, California 90802

TWX: 9103416418 RMP MARINE LGB

ROTTERDAM (NETHERLANDS)

Underwater Cleaning & Diving Rotterdam BV

Telex: 23339-Rotterdam, Netherlands

TENERIFE (CANARY ISLANDS)

Reparaciones y Trabajos Submarinos, S.L.

Telex: 92037, Santa Cruz de Tenerife

TOKYO (JAPAN)

Marine Engineering Corporation

Telex: 02322439 MACLEAN, Tokyo, Japan

THE GULF

Hydrospace International

Sharjah, United Arab Emi,rates

Telex: 8135 HYDRO SH

SUEZ CANAL AREA

Maridive and Oil Services

Rami Station, Alexandria, Egypt

Telex: 54297 NASH

LE HAVRE/ANTIFER (FRANCE)

Societe Maritime de Degazage

Telex: 190571 ©Copyright 1978

Butterworth

Systems Inc.

Butterworth Systems

Butterworth Systems Inc., 224 Park Avenue, Florham Park, N.J. 07932 USA

Telephone (201) 474-1549 Telex 136434

Butterworth Systems (UK) Ltd., 445 Brighton Road, South Croydon, Surrey CR2 6EU, England

Telephone 01-668-6211 Telex 946524

Use this coupon to get the informative 24-page report "IMPROVING SHIP

PERFORMANCE WITH

SCAMP® CLEANING."

It documents the effects of hull fouling and roughness and shows the savings possible with regular

SCAMP hull cleanings.

In North America, mail to:

Butterworth Systems Inc. 224 Park Avenue, Florham Park, N.J. 07932

Elsewhere mail to:

Butterworth Systems (UK) Ltd. 445 Brighton Road, South Croydon,

Surrey CR2 6EU, England

YOUR NAME_

TITLE

COMPANY NAME.

COMPANY ADDRESS.

CITY.

COUNTRY- . MR9

September 1, 1978 7

4

4

6

6