Page 8: of Maritime Reporter Magazine (November 1978)

Read this page in Pdf, Flash or Html5 edition of November 1978 Maritime Reporter Magazine

Levingston Awarded $200 Million To Build

Five Bulk Cargo Ships

Robert J. Blackwell, Assistant

Secretary of Commerce for Mari- time Affairs, has announced the award of a $200,075,000 contract to Levingston Shipbuilding Com- pany, Orange, Texas, to construct five self-sustaining dry-bulk car- go ships. The shipowner is Lev- ingston Falcon I Shipping Com- pany, also of Orange.

Under the federally assisted ship-construction program, the

Maritime Administration (Mar-

Ad), an agency of the U.S. De- partment of Commerce, will pay nearly half the costs of the ves- sels. Additionally, it will pay $37,000 per vessel for the instal- lation of national defense fea- tures. "This project is a significant first step in revitalizing the U.S.- flag dry-bulk fleet which now con- sists of only 19 vessels with a combined cargo-carrying capacity of 556,000 deadweight tons," Mr.

Blackwell said. Pointing out that no new dry-bulk carriers have been built in the United States since 1974, he added, "We cur- rently have under review a mari- time aids program for the dry- bulk industry which should be of further help in upgrading U.S.- flag dry shipping capacity. "The construction of each ship will generate approximately 630 man-years of employment for the

Levingston work force and a like amount for workers in the allied marine supply industry. The total for all five ships could be more than 6,000 man-years of employ- ment for American workers, a significant development at a time when shipbuilding is in a world- wide decline."

The ships will trade worldwide; it is anticipated that they will be carrying grain from U.S. Gulf ports to ports in the Far East, sugar from the Philippines to U.S.

Gulf ports, and wood and iron products from Taiwan to U.S.

Gulf ports.

Each vessel will be 616 feet long, 93 feet wide, and 50 feet deep. Rated at 36,414 dwt and 15,600 horsepower, the ships will have a speed of 16.4 knots. Each will carry a crew of 26.

The ships will be of a design produced by the Japanese ship- building firm of Ishikawajima-

Harima Heavy Industries Co., Ltd. (IHI). Under a separate research and development contract, also announced, Levingston Shipbuild- ing will match $1.2 million from

Mar Ad to employ IHI as a major subcontractor. IHI is to share its production experience and tech- nology with the Texas shipyard, with the information also to be available to the U.S. Government and other U.S. shipyards.

The first ship is scheduled for delivery December 31, 1980, with others to follow at six-month intervals.

MarAd also awarded a 20-year operating-differential subsidy con- tract to Equity Carriers, Inc.,

New York, N.Y., which will bare- boat charter the vessels for 20 years.

The shipowner is a general partnership which includes Lev- ingston Alpha Shipping, Inc., a wholly owned subsidiary of Lev- ingston Navigation Company, Inc., which in turn is owned by the shipyard.

Two other members of the partnership, Falcon Cargo Ships,

Inc., and Falcon Dry Bulk, Inc., are wholly owned by Falcon Equi- ties, Inc., which is owned by C.C.

Wei, Y.J. Hsi, H.M. Hu and the

H.H. Wasson Maritime Trust. The fourth partner, Falcon Investors,

Inc., is wholly owned by Falcon

Carriers, Inc., which is owned by

Colt Industries, the Estate of

Houston H. Wasson, and C.C. Wei.

G.E. Awarded $25 Million

For Gas Turbine Systems

A group led by Mobil Oil Com- pany has placed an order with

General Electric Company, Stam- ford, Conn., for five gas turbine power systems.

The contract, amounting to ap- proximately $25 million, is for the power systems to be used on the Statfjord "B" drilling plat- form on the Norwegian waters of the North Sea.

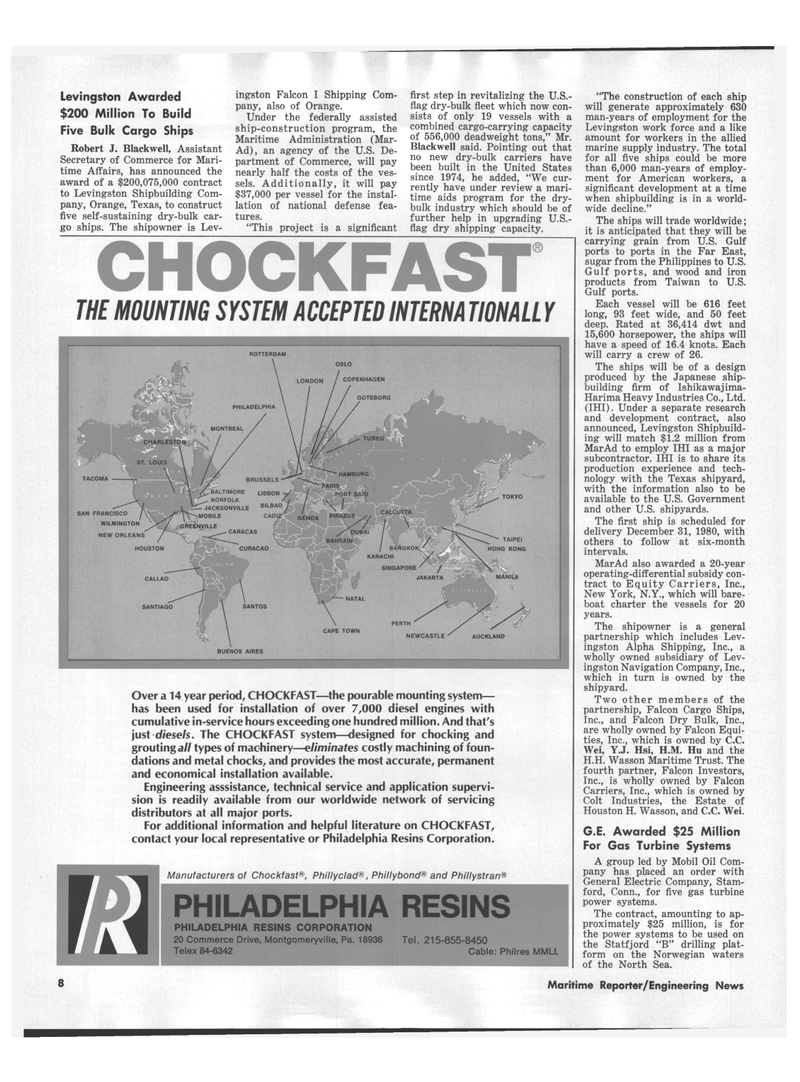

CHOCKFAST

Over a 14 year period, CHOCKFAST—the pourable mounting system— has been used for installation of over 7,000 diesel engines with cumulative in-service hours exceeding one hundred million. And that's just diesels. The CHOCKFAST system—designed for chocking and grouting all types of machinery—eliminates costly machining of foun- dations and metal chocks, and provides the most accurate, permanent and economical installation available.

Engineering asssistance, technical service and application supervi- sion is readily available from our worldwide network of servicing distributors at all major ports.

For additional information and helpful literature on CHOCKFAST, contact your local representative or Philadelphia Resins Corporation.

Manufacturers of Chockfast®, PhillycladPhillybond® and Phillystran®

PHILADELPHIA RESINS

PHILADELPHIA RESINS CORPORATION 20 Commerce Drive, Montgomeryville, Pa. 18936 Tel. 215-855-8450

Telex 84-6342 Cable: Philres MMLL

OSLO

COPENHAGEN LONDON

GOTEBORG

IBURG

SAID TOKYO ^ TAIPEI

HONG KONG BANGKOI

KARACHI

SINGAPORE

PERTH

CAPE TOWN

NEWCASTLE AUCKLAND

ST. LOUIS

TACOMA

BALTIMORE ^ NORFOLK

JACKSONVILLE SAN FRANCISCO

WILMINGTON

MOBILE

GREENVILLE

CARACAS NEW ORLEANS

HOUSTON

CALLAO

SANTOS SANTIAGO

THE MOUNTING SYSTEM ACCEPTED INTERNA TIONALL Y m 12

Maritime Reporter/Engineering News

7

7

9

9