Page 19: of Maritime Reporter Magazine (December 1978)

Read this page in Pdf, Flash or Html5 edition of December 1978 Maritime Reporter Magazine

Our LTG reheat boiler.

For increased reliability in today's energy-saving reheat steam plants.

The LTG (Low Tempera- ture Gas) reheat boiler from

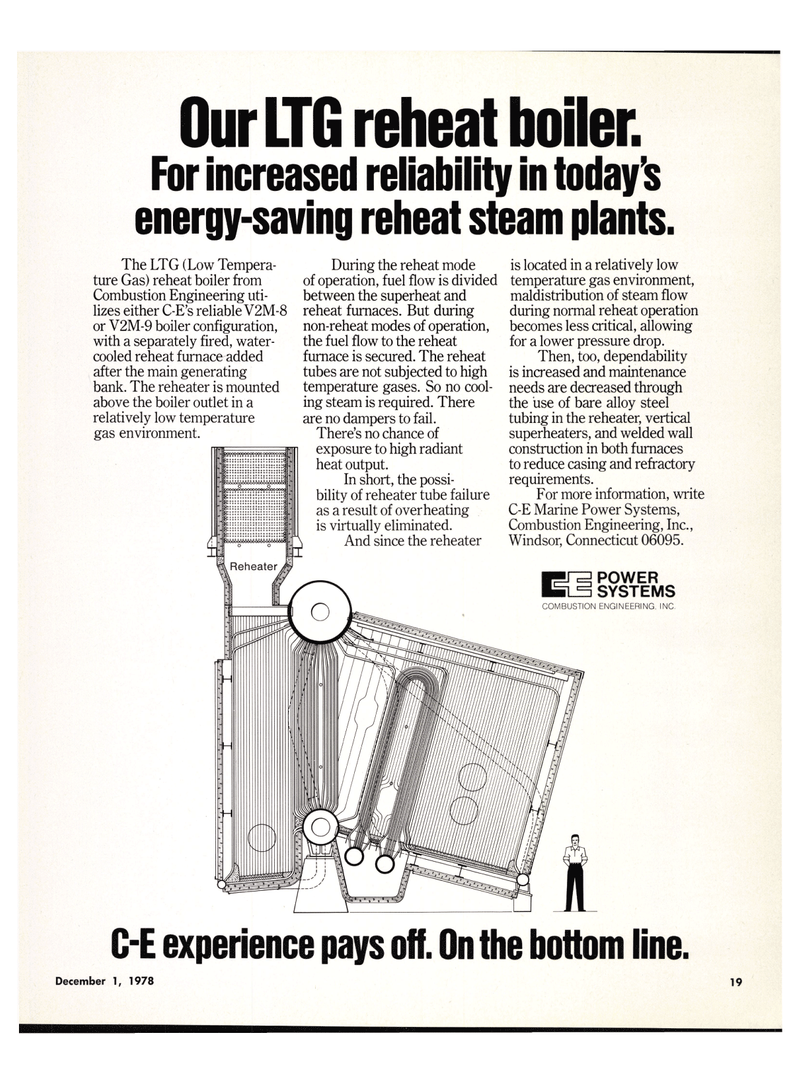

Combustion Engineering uti- lizes either C-E's reliable V2M-8 or V2M-9 boiler configuration, with a separately fired, water- cooled reheat furnace added after the main generating bank. The reheater is mounted above the boiler outlet in a relatively low temperature gas environment.

During the reheat mode of operation, fuel flow is divided between the superheat and reheat furnaces. But during non-reheat modes of operation, the fuel flow to the reheat furnace is secured. The reheat tubes are not subjected to high temperature gases. So no cool- ing steam is required. There are no dampers to fail.

There's no chance of exposure to high radiant heat output.

In short, the possi- bility of reheater tube failure as a result of overheating is virtually eliminated.

And since the reheater is located in a relatively low temperature gas environment, maldistribution of steam flow during normal reheat operation becomes less critical, allowing for a lower pressure drop.

Then, too, dependability is increased and maintenance needs are decreased through the use of bare alloy steel tubing in the reheater, vertical superheaters, and welded wall construction in both furnaces to reduce casing and refractory requirements.

For more information, write

C-E Marine Power Systems,

Combustion Engineering, Inc.,

Windsor, Connecticut 06095.

POWER •LEd SYSTEMS

COMBUSTION ENGINEERING, INC

C-E experience pays off. On the bottom line,

December 1, 1978 13

18

18

20

20