Page 17: of Maritime Reporter Magazine (February 15, 1980)

Read this page in Pdf, Flash or Html5 edition of February 15, 1980 Maritime Reporter Magazine

Parsons Brinckerhoff

Will Develop Boston

Container Terminal

The Boston office of Parsons

Brinckerhoff, the engineering, ar- chitectural, and planning firm, is currently at work on a project that will transform the west end of the Massachusetts Port Au- thority's Castle Island Terminal into a modern container terminal.

This is a first step in significantly increasing the container-handling capacity of Boston Harbor.

When completed, the South

Boston Terminal located across the Harbor from Logan Airport, will be upgraded to include a 1,000- foot berth, two container cranes, and a 10-acre upland area with terminal support facilities.

Ground-breaking ceremonies are expected to take place this month.

The scope of work includes de- tailed inspection of the existing marginal timber wharf, rehabili- tating and upgrading the wharf foundation, extending the wharf deck, and adding crane rail foun- dations to support the crane run- way. Due to airplane glide path limitations near the airport, low profile cranes will be specified.

Further steps in the rehabilita- tion call for the design of three buildings—an administrative cen- ter, a service garage, and an em- ployee facility—as well as the de- sign of all new utilities, security fencing, and ship's services.

Parsons Brinckerhoff will fol- low the project through to com- pletion, with construction man- agement services geared toward keeping Castle Island Terminal's busy shipping schedule in oper- ation while the conversion is un- derway. A fast-track design and construction schedule is being used to achieve startup in the first quarter of 1981.

Common Brothers U.S.A.

Appoints Leo McKay

Common Brothers U.S.A. Lim- ited, the New York arm of the

Common Brothers Group, New- castle, England-based shipowning and shipbroking company, recent- ly announced the appointment as a nonexecutive director of Leo

McKay, president of S.E.L. Ma- duro (Florida).

Mr. McKay brings to the Com- mon Brothers board over 30 years of experience in the U.S. steam- ship business. Most recently, he is based in Miami, where he heads

S.E.L. Maduro's Florida operation.

Common Brothers' New York office is active in the sale and purchase of vessels, and addition- ally specializes in the chartering and sale of roll-on roll-off and con- tainer vessels.

Free Bulletin Offered

On Marine Alternators For

Work, Crew, Supply Boats

A free technical bulletin just released by the LIMA Electric

Company, Inc., Lima, Ohio, com- pletely describes the company's

SER^ (Synchronous Externally

Regulated) Alternators for ma- rine applications.

The 361 and 441 Frame SER 1,200 RPM brushless alternators are built especially for use on work, crew, supply and fish boats because of the low noise and vi- bration levels associated with lower engine operating speed.

They are easily adaptable to all makes of 1,200 RPM marine gen- set engines.

LIMA alternator foot mounting is directly interchangeable with most 1,200 RPM alternators in service, allowing easy field re- placement. Standard LIMA 1,200

RPM SER Alternators have ABS approval, which simplifies certi- fication of particular units for specific hulls.

For copies of the free literature or more information on 1,200

RPM alternators, write to J.D.

Bourque, Sales Manager, Lima

Electric Company, 200 East Chap- man Road, Lima, Ohio 45802.

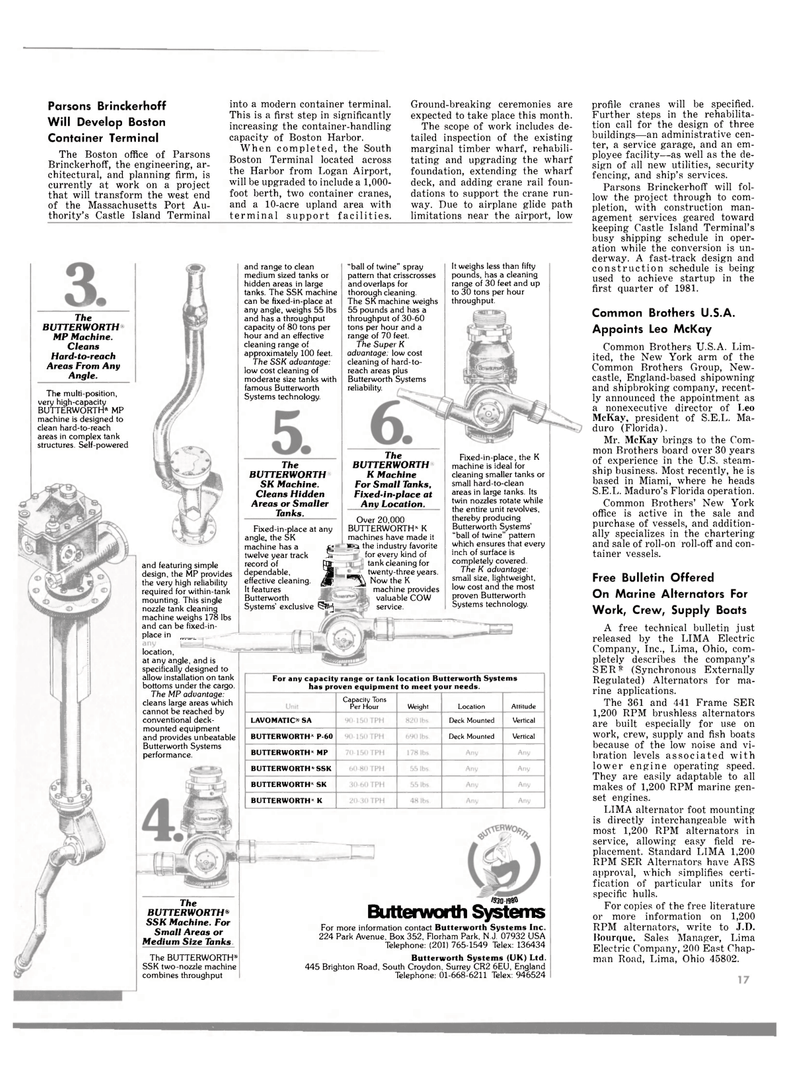

It weighs less than fifty pounds, has a cleaning range of 30 feet and up to 30 tons per hour throughput. and range to clean medium sized tanks or hidden areas in large tanks. The SSK machine can be fixed-in-place at any angle, weighs 55 lbs and has a throughput capacity of 80 tons per hour and an effective cleaning range of approximately 100 feet.

The SSK aduantage: low cost cleaning of moderate size tanks with famous Butterworth

Systems technology. "ball of twine" spray pattern that crisscrosses and overlaps for thorough cleaning.

The SK machine weighs 55 pounds and has a throughput of 30-60 tons per hour and a range of 70 feet.

The Super K aduantage: low cost cleaning of hard-to- reach areas plus

Butterworth Systems reliability.

The

BUTTERWORTH

MP Machine.

Cleans

Hard-to-reach

Areas From Any

Angle.

The multi-position, very high-capacity

BUTTERWORTH® MP machine is designed to clean hard-to-reach areas in complex tank structures. Self-powered

The

BUTTERWORTH

K Machine

For Small Tanks,

Fixed-in-place at

Any Location.

Fixed-in-place, the K machine is ideal for cleaning smaller tanks or small hard-to-clean areas in large tanks. Its twin nozzles rotate while the entire unit revolves, thereby producing

Butterworth Systems' "ball of twine" pattern which ensures that every inch of surface is completely covered.

The K advantage: small size, lightweight, low cost and the most proven Butterworth

Systems technology.

The

BUTTERWORTH

SK Machine.

Cleans Hidden

Areas or Smaller

Tanks.

Over 20,000

BUTTERWORTH "- K machines have made it gga the industry favorite for every kind of tank cleaning for twenty-three years. ^^ Now the K machine provides valuable COW service.

Fixed-in-place at any angle, the SK machine has a g twelve year track S record of pit dependable, '"Jjj effective cleaning. Jp

It features

Butterworth

Systems' exclusive ^Bj and featuring simple design, the MP provides the very high reliability required for within-tank mounting. This single nozzle tank cleaning machine weighs 178 lbs and can be fixed-in- place in ^ location, at any angle, and is specifically designed to allow installation on tank bottoms under the cargo.

The MP aduantage: cleans large areas which cannot be reached by conventional deck- mounted equipment and provides unbeatable

Butterworth Systems performance.

For any capacity range or tank location Butterworth Systems has proven equipment to meet your needs.

Capacity Tons

Per Hour Attitude Weight Location

LAVOMATIO SA Deck Mounted Vertical

BUTTERWORTH * P-60 Deck Mounted Vertical

BUTTERWORTH" MP

BUTTERWORTH" SSK

BUTTERWORTH SK

BUTTERWORTH" K '930-1980 Butterworth Systems

For more information contact Butterworth Systems Inc. 224 Park Avenue, Box 352, Florham Park, N.J. 07932 USA

Telephone: (201) 765-1549 Telex: 136434

Butterworth Systems (UK) Ltd. 445 Brighton Road, South Croydon, Surrey CR2 6EU, England

Telephone: 01-668-6211 Telex: 946524

The

BUTTERWORTH®

SSK Machine. For

Small Areas or

Medium Size Tanks

The BUTTERWORTH®

SSK two-nozzle machine combines throughput

16

16

18

18