Page 27: of Maritime Reporter Magazine (February 15, 1980)

Read this page in Pdf, Flash or Html5 edition of February 15, 1980 Maritime Reporter Magazine

$76 Million Awarded

To Ingalls By Navy

For Additional CG-48 Work

Litton Systems, Inc., Ingalls

Shipbuilding Division, Pascagoula,

Miss., is being awarded a $76,- 153,578 modification to a previ- ously awarded cost-plus-award- fee contract for long lead time materials for the construction of guided missile cruiser CG-48 (for- merly DDG-48). The Naval Sea

Systems Command is the con- tracting activity. (N00024-78-C- 2316)

Second Tsavliris Bulkcarrier

Delivered By CCN

Companhia Comercio e Nave- gacao (CCN) of Brazil recently delivered the Claire A. Tsavliris, a 26,500-dwt Prinasa 26/15 bulk- carrier, to her owners the Greek

Tsavliris Group.

The second vessel to be deliv- ered by CCN for Greek account, the Claire A. Tsavliris joins her sistership, the Alexandros G.

Tsavliris, which was delivered last year.

The vessel was put into service upon delivery. The Claire A.

Tsavliris has full container capa- bility and can carry about 600 twenty-foot containers, as well as timber, on deck. She has a lifting capacity of 32 tons on twin crane operation, and can carry general cargo, containers, iron ore, and a variety of other goods in her five holds.

Equipped with a 13,300-bhp diesel engine, the vessel can de- velop a service speed of 15.4 knots at 85 percent MCR. The ship's length overall is 173.16 meters, length bp, 163 meters, breadth, molded, 16.6 meters, depth, mold- ed, 13.5 meters, and a mean sum- mer draft of 9.72 meters (about 568 feet by 535 feet by 54 feet by 44 feet by 31 feet).

McDermott Develops New

Pipeline Welding System —Literature Available

J. Ray McDermott & Co., Inc. of New Orleans, La., has com- pleted tests on a new automatic marine pipeline welding system.

McDermott reports the system, under development since 1976, will increase the speed and qual- ity with which large diameter pipe can be welded aboard marine lay barges. The company is offer- ing a free, full-color brochure de- scribing the new method.

This system utilizes the gas tungsten arc welding process with two carriages that operate on a forged aluminum track, hinged at its top to open and close like a clamshell. Each carriage positions two torches, and each torch welds 90° of the pipe circumference.

The carriages are mechanical mir- ror images of each other, and they contain all of the mechan-

February 15, 1980 ical parts that convert electronic commands into the physical mo- tion to perform the weld. Pipe ends are prepared for welding and aligned using conventional end- facing machines and internal line- up clamps.

At each of five weld stations, four solid-state 600-ampere di- rect-current power supplies with 100 percent duty cycle are used.

A sequence and control console manages the system at each sta- tion. The modular design of the console permits quick removal and replacement of components.

Consumables required for the

McDermott system include helium gas, argon gas, 0.045-inch-diam- eter welding wire on 12-pound spools, 0.156-inch-diameter tung- sten electrodes, torch gas lenses, and torch collets.

McDermott estimates that, con- servatively, the weld cycle time required for 36-inch-diameter, 1-inch-thick pipe will be less than five minutes when five or more stations are used. This equals about 240 joints per day (9,600 feet) if no weld repairs are re- quired. Developmental welds have exceeded API STD 1104 require- ments for both X-ray inspection and mechanical testing.

For more information on the system and a free brochure, write to William Finger, P.O. Box 60035,

New Orleans, La. 70160.

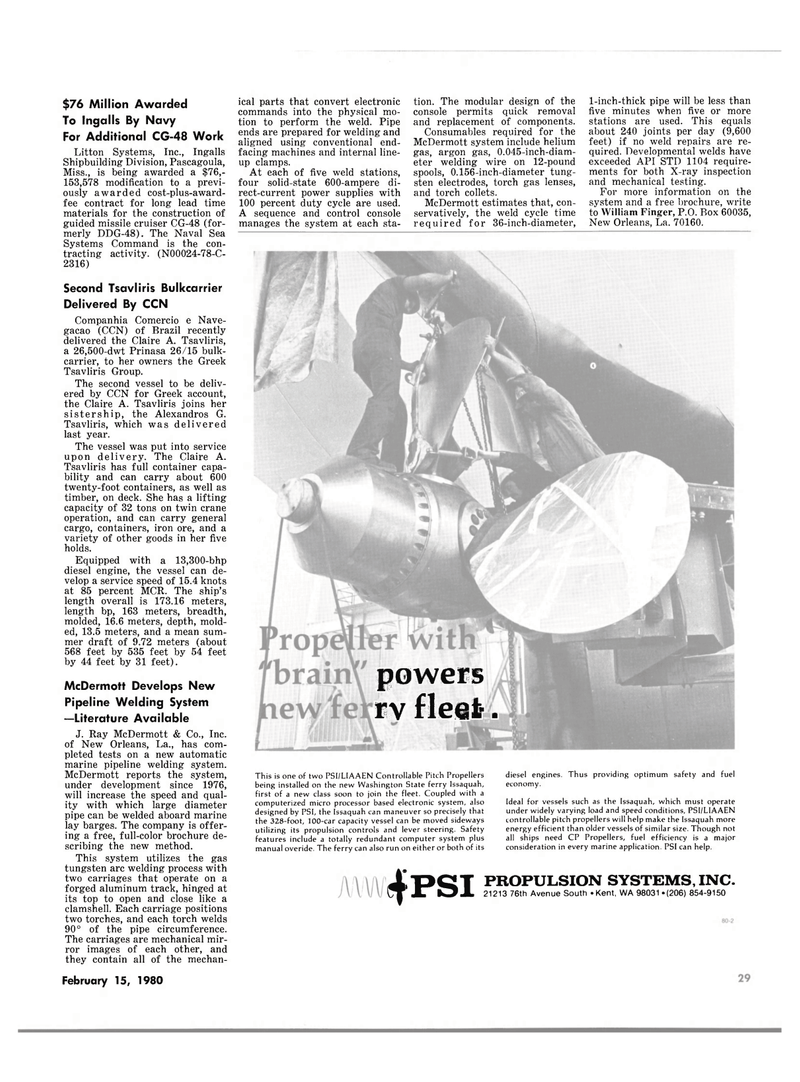

This is one of two PSI/LIAAEN Controllable Pitch Propellers being installed on the new Washington State ferry Issaquah, first of a new class soon to join the fleet. Coupled with a computerized micro processor based electronic system, also designed by PSI, the Issaquah can maneuver so precisely that the 328-foot, 100-car capacity vessel can be moved sideways utilizing its propulsion controls and lever steering. Safety features include a totally redundant computer system plus manual overide. The ferry can also run on either or both of its 4PSI diesel engines. Thus providing optimum safety and fuel economy.

Ideal for vessels such as the Issaquah, which must operate under widely varying load and speed conditions, PSI/LIAAEN controllable pitch propellers will help make the Issaquah more energy efficient than older vessels of similar size. Though not all ships need CP Propellers, fuel efficiency is a major consideration in every marine application. PSI can help.

PROPULSION SYSTEMS, INC. 21213 76th Avenue South 'Kent, WA 98031 -(206) 854-9150 11 powers rv fleet-.

26

26

28

28