Page 9: of Maritime Reporter Magazine (April 15, 1980)

Read this page in Pdf, Flash or Html5 edition of April 15, 1980 Maritime Reporter Magazine

Gus Ruetenik Promoted

To Environmental Products

Manager At Seaward

Seaward International, Inc. of

Falls Church, Va., recently an- nounced the promotion of Gus

Ruetenik to the position of envi- ronmental products manager.

Gus Ruetenik

In his new capacity, Mr. Ruete- nik will have overall business re- sponsibility for Seaward Inter- national's environmental products.

These responsibilities include sales and marketing, administration, equipment design and engineer- ing, liaison with production, and product promotion activities of the company.

Mr. Ruetenik is a graduate of the University of New Hampshire with a B.S. degree in mechanical engineering and a minor in ocean engineering. He joined Seaward

International in 1977 as an ocean engineer and was project engi- neer prior to his promotion.

Seaward International's pollu- tion control products include the

SEA FENCE oil containment boom. Mr. Ruetenik was instru- mental in the design and initial production of the SEA FENCE, which was originally designed for the U.S. Navy. Seaward also man- ufactures the SLURP, floating weir-type oil skimmer, and SEA

CUSHION® foam-filled marine fenders.

Information Is Available

On Three New Doppler

Speed Logs By Raytheon

Literature is now available de- scribing three new Doppler speed logs that use bottom-reflected sound to provide accurate speed data from 0.01 knot to 40 knots, from Raytheon Marine Company.

The Raytheon Doppler systems track the bottom to depths of 1,000 feet using acoustic beams directed ahead, astern, and to each side of the vessel. In deeper water, the system automatically shifts from bottom-tracking to watermass-tracking. In addition to calculating speed, the Raytheon

Doppler speed logs also provide a digital depth display to a maxi- mum of 1,000 feet and can be read in feet, fathoms, or meters.

The model DSL-250, simplest in the Raytheon line, is a single- axis, dual-beam system designed for providing continuous accurate speed and depth resolution in the ship's fore/aft axis.

In the "normal" operating mode, at speeds less than 9.99 knots, speed is displayed in hundredths of a knot. This ensures that the system will sense movement of as little as one foot per minute when approaching anchorage, moorings, or berths. Other features include an adjustable depth alarm, built- in self-test circuitry, and a me- chanical distance-run log.

The model DSL-350 is a dual- axis, dual-beam system for se- lectable resolution of the ship's fore/aft and port/starboard speed. The port/starboard or athwartships speed feature is es- pecially useful in determining set and drift from the steered course.

The model DSN-450 is a dual- axis, four-beam sonar navigator that provides continuous, simul- taneous readout of the fore/aft and athwartships speed.

On all three models, data is processed for digital display on an easily read 11-inch by 14-inch bridge display/control unit and for input to radars, other ship- board electronic equipment, and integrated navigation systems.

Weatherproof digital and analog repeater displays are also avail- able for use in exposed locations.

Additional information and complete specifications can be ob- tained by writing to Stanley

Clark, Raytheon Marine Compa- ny, 676 Island Pond Road, Man- chester, N.H. 03103.

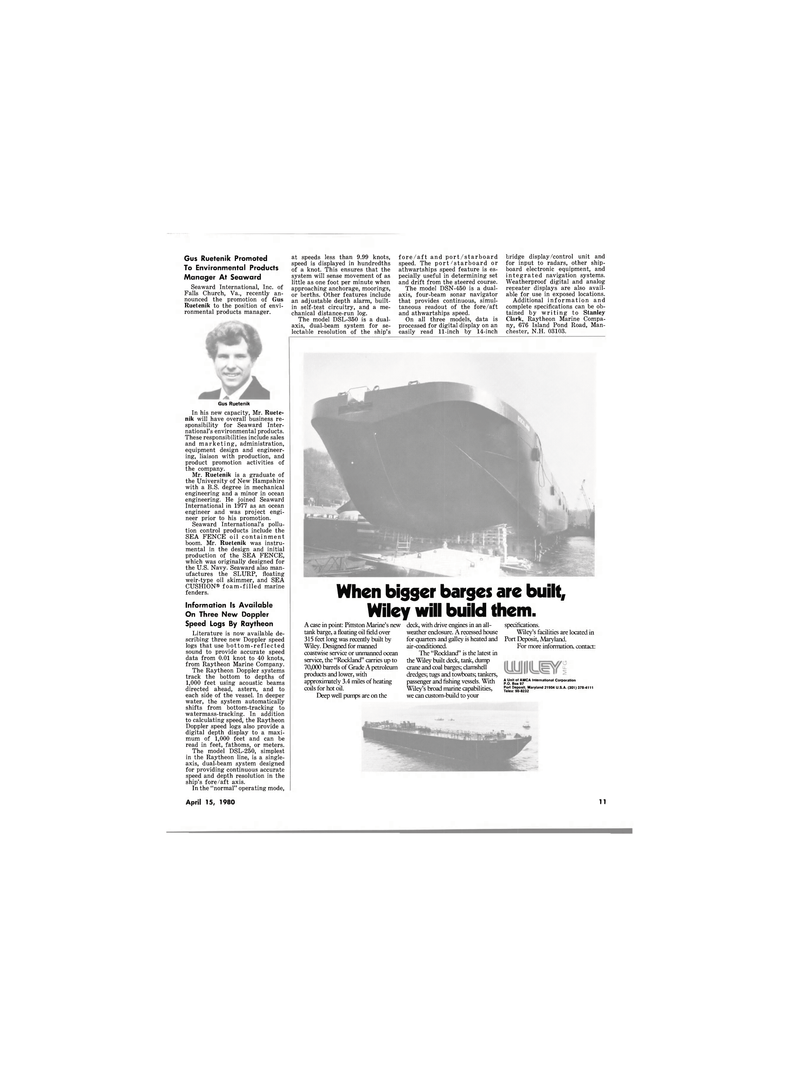

When bigger barges are built,

Wiley will build them.

A case in point: Pittston Marine's new tank barge, a floating oil field over 315 feet long was recently built by

Wiley. Designed for manned coastwise service or unmanned ocean service, the "Rockland" carries up to 70,000 barrels of Grade A petroleum products and lower, with approximately 3.4 miles of heating coils for hot oil.

Deep well pumps are on the deck, with drive engines in an all- weather enclosure. A recessed house for quarters and galley is heated and air-conditioned.

The "Rockland" is the latest in the Wiley built deck, tank, dump crane and coal barges; clamshell dredges; tugs and towboats; tankers, passenger and fishing vessels. With

Wiley's broad marine capabilities, we can custom-build to your specifications.

Wiley's facilities are located in

Port Deposit, Maryland.

For more information, contact:

A Unit of AMCA International Corporation

P.O. Box 97

Port Deposit, Maryland 21904 U.S.A. (301) 378-4111

Telex: 90-8232

April 15, 1980 11

8

8

10

10