Page 19: of Maritime Reporter Magazine (June 15, 1980)

Read this page in Pdf, Flash or Html5 edition of June 15, 1980 Maritime Reporter Magazine

1

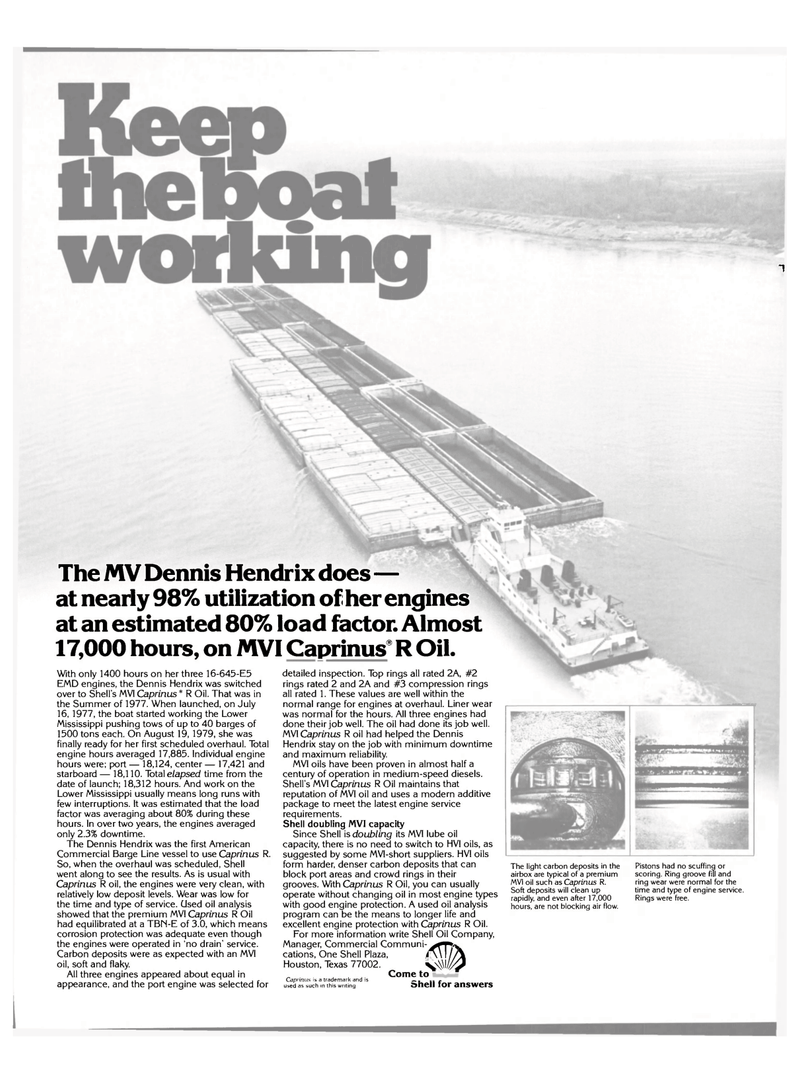

The MV Dennis Hendrix does— at nearly 98% utilization of her engines at an estimated 80% load factor. Almost 17,000 hours, on MVI Caprinus R Oil.

With only 1400 hours on her three 16-645-E5

EMD engines, the Dennis Hendrix was switched over to Shell's MVI Caprinus * R Oil. That was in the Summer of 1977. When launched, on July 16, 1977, the boat started working the Lower

Mississippi pushing tows of up to 40 barges of 1500 tons each. On August 19, 1979, she was finally ready for her first scheduled overhaul. Total engine hours averaged 17,885. Individual engine hours were; port — 18,124, center — 17,421 and starboard — 18,110. Total elapsed time from the date of launch; 18,312 hours. And work on the

Lower Mississippi usually means long runs with few interruptions. It was estimated that the load factor was averaging about 80% during these hours. In over two years, the engines averaged only 2.3% downtime.

The Dennis Hendrix was the first American

Commercial Barge Line vessel to use Caprinus R.

So, when the overhaul was scheduled, Shell went along to see the results. As is usual with

Caprinus R oil, the engines were very clean, with relatively low deposit levels. Wear was low for the time and type of service. Used oil analysis showed that the premium MVI Caprinus R Oil had equilibrated at a TBN-E of 3.0, which means corrosion protection was adequate even though the engines were operated in 'no drain' service.

Carbon deposits were as expected with an MVI oil, soft and flaky.

All three engines appeared about equal in appearance, and the port engine was selected for detailed inspection. Top rings all rated 2A, #2 rings rated 2 and 2A and #3 compression rings all rated 1. These values are well within the normal range for engines at overhaul. Liner wear was normal for the hours. All three engines had done their job well. The oil had done its job well.

MVI Caprinus R oil had helped the Dennis

Hendrix stay on the job with minimum downtime and maximum reliability.

MVI oils have been proven in almost half a century of operation in medium-speed diesels.

Shell's MVI Caprinus R Oil maintains that reputation of MVI oil and uses a modern additive package to meet the latest engine service requirements.

Shell doubling MVI capacity

Since Shell is doubling its MVI lube oil capacity, there is no need to switch to HVI oils, as suggested by some MVI-short suppliers. HVI oils form harder, denser carbon deposits that can block port areas and crowd rings in their grooves. With Caprinus R Oil, you can usually operate without changing oil in most engine types with good engine protection. A used oil analysis program can be the means to longer life and excellent engine protection with Caprinus R Oil.

For more information write Shell Oil Company,

Manager, Commercial Communi-^^p",-;,, cations, One Shell Plaza, i' X

Houston, Texas 77002. VW^

Come to

Cdprinus is a trademark and is „ , .. c used as such in this writing Snell IOr answers

The light carbon deposits in the Pistons had no scuffing or airbox are typical of a premium

MVI oil such as Caprinus R.

Soft deposits will clean up rapidly, and even after 17,000 hours, are not blocking air flow. scoring. Ring groove fill and ring wear were normal for the time and type of engine service.

Rings were free.

18

18

20

20